For decades, KOSMEK has been the market leader in Asia. The increased demand in KOSMEKs patented Low-Pressure-Technology brought this unique company to Europe almost 10 years ago. Since then, the business has grown more than 30% annually. The success story started with a technical limitation: nearly 40 years ago Japanese car manufactures limited their maximum hydraulic pressure to 70 bar. KOSMEK has stood up to this limitation and has created one of the most innovative developments of the past 30 years for this market: products that produce higher clamping forces with low pressure, guarantee higher accuracy and are maintenance-free.

E.E: What are the main areas of activity of the company?

KOSMEK: KOSMEK has products for workholding, factory automation, die-casting and injection molding machines as well as for presses. 360 national and international patents currently protect these products.

E.E: What’s the news for 2020 about new products?

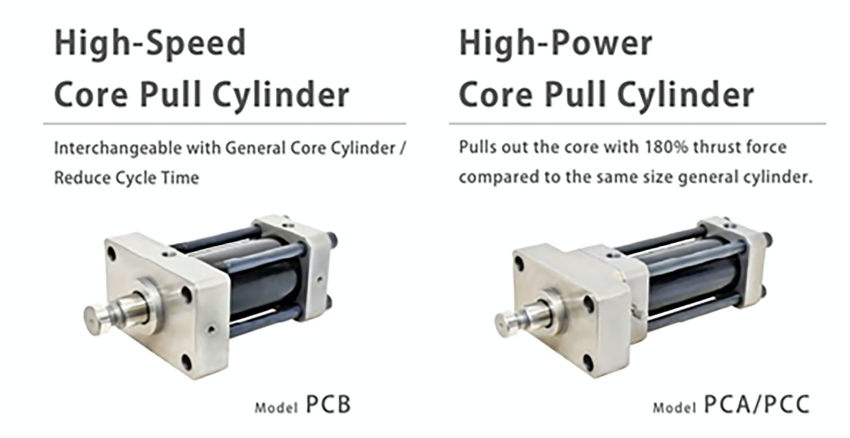

KOSMEK: “High-Power” and “High-Speed” core pull cylinders. If the core-pull is influencing the cycle time KOSMEK cylinders can reduce cycle times by up to 5 seconds. The patents for this technology are based on the principle of force increase by double pistons on the one hand–, on the other hand by speed increase due to smaller cross-sections and also on the inimitable “high-power-patent”. In any case KOSMEK can offer the ideal cylinder.

If high force is required immediately, like at the beginning of the core pull due to the “sticking effect”, the cylinder only applies this force in the first 20 mm of the path. The remaining path is taken with the highest possible speed (= “high-speed” core pull cylinder).

If you need an even higher force, like it could be applied with a commonly dimensioned cylinder and installation limitations are existent, the “high-power” cylinder from KOSMEK helps. The “high-power” cylinder applies 180% of the force with the same dimensions. Again, only in the first fifth of the movement. After that the cylinder works with maximum speed until piston cushioning at the end. This saves up to 5 seconds of cycle time. In situations where the core has to resist the force induced by the injected material, KOSMEK takes advantage of its “high-power” patent. This multiplies forces via ramps inside the cylinder.

E.E: What are the ranges of traded products?

KOSMEK: Workholding, factory automation, welding, washing, die-casting, injection molding and presses.

E.E: At what stage is the market where you are currently active?

KOSMEK: Saturated.

E.E: What can you tell us about market trends?

KOSMEK: The market is seeking for more efficiency to remain competitive. Especially in Europe it is vital to have efficient production processes because labor costs are rising every year. And here KOSMEK products help because 360 patents stand for technology leadership. At KOSMEK you automatically get the most innovative product on the market. As the only company in the world, we can equip the entire production process with our products. From the positioning and clamping of the workpiece to factory automation to the initial equipping of machine tools. This not only reduces the complexity of planning with different contact persons, it also simplifies resource management.

E.E: What are the most innovative products marketed?

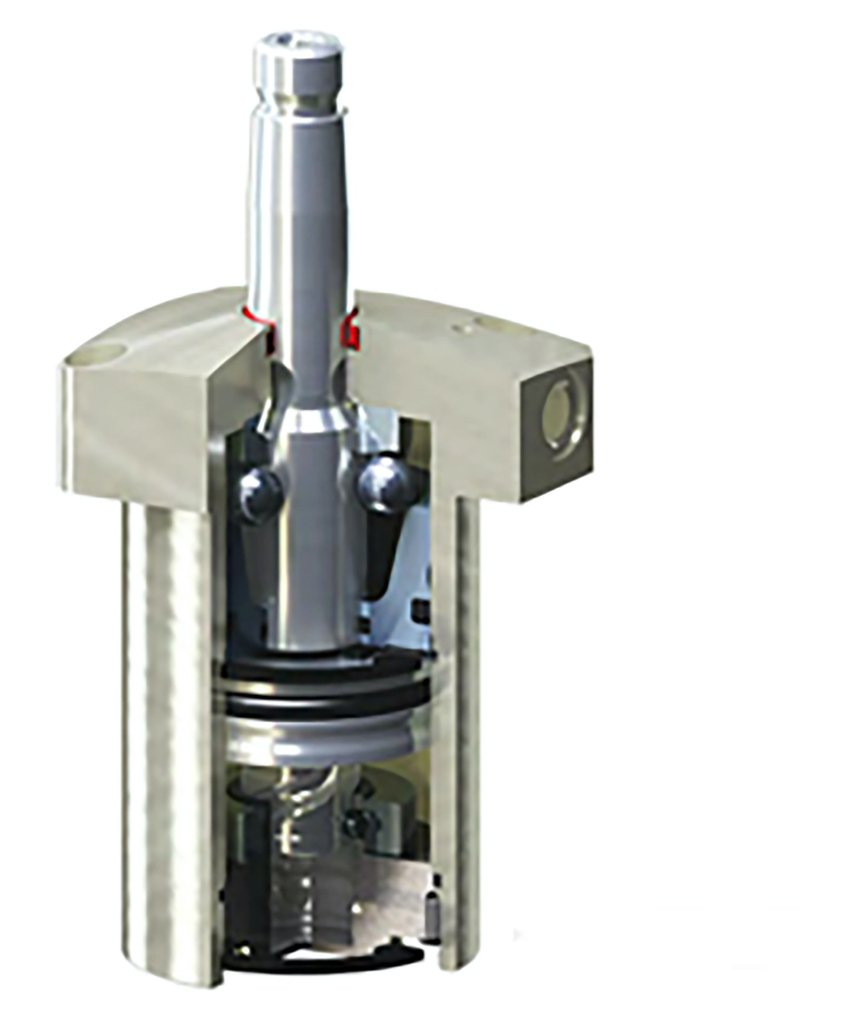

KOSMEK: “High-Power-Technology”. A quantum leap for the machining industry was the patent application of KOSMEK for a simple but effective mechanism. – The so called “high-power-patent” uses a power amplification via ramps, which are located inside the cylinder. In best case, this force enhancement can be a tripling of the purely by the hydraulic or pneumatic induced force. Or vice versa, you can use a smaller size for the same power requirement and use the gained space for larger workpieces.

As a positive side effect, a mechanical locking system is also provided, which allows pneumatic cylinders to apply holding forces even in case of pressure loss. If you work against the cylinder-force, in case of a high-power-version you work against a holding force, which exceeds the force originally applied pneumatically or hydraulically by a factor of seven.

If the lever sinks, in the case of KOSMEK, the cylinder compensates this movement and the clamping and holding force remains up. This can happen if e.g. during machining a rough cast surface pits due to the high forces. This effect enables unimagined new possibilities, such as for example machining against the clamping lever, higher feed and larger tools or five-sided machining with only one clamping.

This technology is used throughout the entire product range of KOSMEK. – From High-Power-Core-Push-Cylinders to various clamping cylinders for machining devices and pallet clamping systems to smallest hole clamps for the semiconductor industry.

In any case, KOSMEK “High-Power” products are smaller, lighter, stronger and maintenance free – enabling initial cost savings of up to 30%!

E.E: What estimations do you have for 2020?

KOSMEK: In Europe we see a transformation of thinking: – From “we buy again the same components as we always did” to “let’s find out if we can find components on the market which help us increasing our OEE!”.