L.B. Bohle with the headquarter in Germany, is one of the largest system suppliers for the pharmaceutical processing industry and related sectors. Internationally active, the company focuses on machinery and equipment as well as process technology and components. In addition, L.B. Bohle offers sustainable solutions for demanding production processes in batch and continuous manufacturing.

The company offers a comprehensive product portfolio for your pharmaceutical solids production. Their products provide added value for your production. L.B. Bohle has the optimal machine for your process, from weighing, to wet and dry granulation, grinding and sieving, blending, tablet coating, tablet checking through to product handling.

Easy Engineering: What are the main areas of activity of the company?

L.B. Bohle: L.B. Bohle is the most innovative technology company in the planning and implementation of machines and processes for the pharmaceutical solids production. As a technology leader in machines, systems, and processes for the pharmaceutical tablet manufacture, we offer retail or all-in-one solutions for the entire production process.

The headquarters are in Ennigerloh, Germany. About 280 specialists build a highly qualified team. The manufacturer has subsidiaries in Sassenberg and Ennigerloh (Plant 2, Plant 3, and´Plant 4), Germany, L.B. Bohle LLC, in Warminster, PA, USA and L.B. Bohle India Private Ltd. in Ahmedabad, India.

Furthermore, the company is represented all over the world in about 40 countries by independent sales agencies.

E.E: What’s the news about new products?

L.B. Bohle: Product efficiency increase is the central benefit of L.B. Bohle. To this end, we offer both complete production plants and solutions for individual production steps. The basis for this is fast development and production of sophisticated, pragmatic, and customized applications.

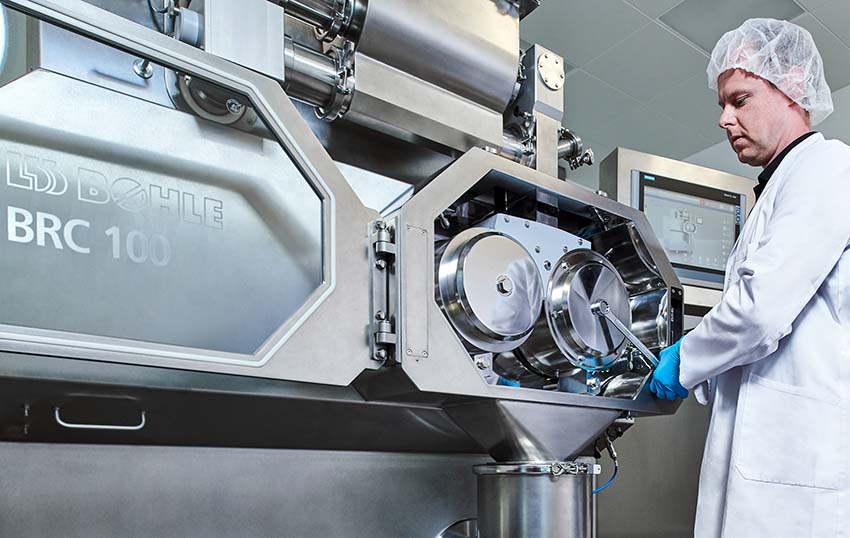

In the last few years, we have made several innovations for different production steps. For batch processing steps, we can name new equipment in dry and granulation, sieving and milling, and product handling.

Furthermore, we have introduced equipment for the continuous manufacturing of pharmaceutical solids. L.B. Bohle offers stand-alone systems for the Continuous Manufacture of twin-screw granulation, drying, dry granulation and coating as well as the QbCon® production plant.

E.E: What are the ranges of products?

L.B. Bohle: We offer a comprehensive product portfolio for the pharmaceutical production. With machines and systems for the following process steps, we are going to provide daily profit to the production of our customers in batch and continuous manufacturing:

- Weighing

- Dry and wet granulation

- Milling and sieving

- Container blending

- Tablet coating

- Tablet checking

- Product handling

E.E: At what stage is the market where you are currently active?

L.B. Bohle: L.B. Bohle is one of the most requested suppliers for pharmaceutical equipment worldwide. Furthermore, we are a pioneer in continuous manufacturing.

E.E: What can you tell us about market trends?

L.B. Bohle: You can find the following trends on the market:

- Increased Demand for Personalised Medicine

- The demand for machines that can process active or highly potent ingredients continues to rise

- Introduction of Continuous Manufacturing

E.E: What are the most innovative products marketed?

L.B. Bohle: Beside tablet coating machines, machines of the QbCon series for continuous manufacturing are the most innovative product marketed.

The QbCon® continuous manufacturing systems allow for production of pharmaceutical solids from powder to the coated tablet with a throughput from 5 to 25 kg/h. QbCon® stands out with its modular design that ensures maximum flexibility and efficiency for the customer.

QbCon® enables three production processes:

- Continuous direct compression

- Continuous wet granulation

- Continuous dry granulation

QbCon® 1, a continuous twin-screw granulator and truly continuous dryer, is the only system for research and development world-wide that meets the quality demands of pharmaceutical manufacture.

Furthermore, with BCD fluidized bed dryer, L.B. Bohle enables continuous drying of granules for the first time.

E.E: What estimations do you have for 2022?

L.B. Bohle After a very successful year with strong sales growth in 2021, we are going to estimate a continuous growth in 2022. Thanks to a strong order entry for 2022, we firmly expect the trend to continue.

We plan to consolidate and expand our existing position as an expert in batch and continuous manufacturing and generate further growth worldwide.