Latent Heat Solutions LLC (LHS®) is a thermal engineering company focused on improving safety, preventing thermal runaway, and incorporating thermal management in Li-ion battery systems, electronics, and industrial systems.

LHS is part of the CAVU group which consists of Microtek Labs Inc. and American Thermal Instruments (ATI). Microtek is a manufacturer of passive thermal management materials based on phase change materials, and ATI designs and manufacturers temperature monitoring and sensing equipment

Interview with Mark Hartmann, CTO at Latent Heat Solutions LLC.

Easy Engineering: What are the main areas of activity of the company?

Mark Hartmann: LHS thermal management materials provide energy absorption and heat dissipation characteristics for passive thermal control. These materials are designed to prevent thermal runaway, maintain homogenous temperatures across cells, and reduce battery overheating due to fast charging/ discharging which leads to less battery degradation and an increased battery life.

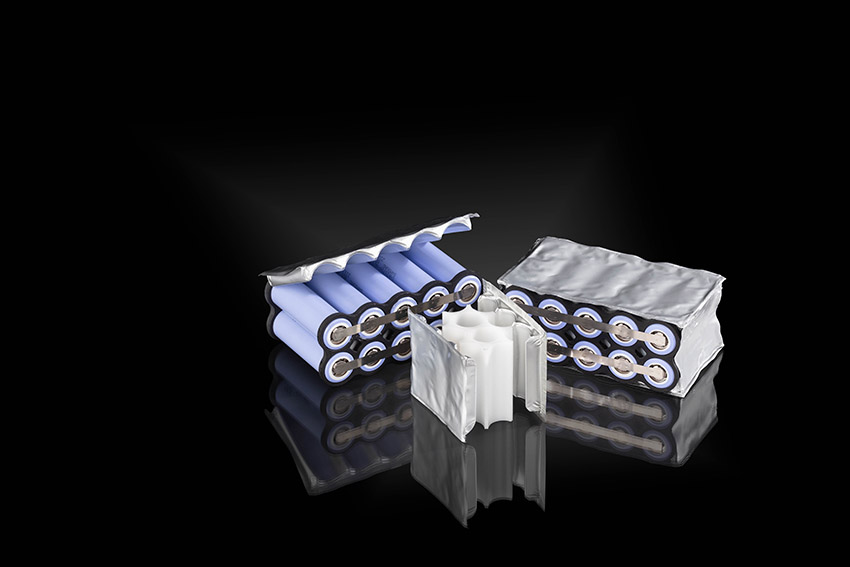

LHS produces two main product lines. The XTS runaway prevention system provides dual benefits by eliminating thermal runaway and providing thermal management to the cells by absorbing and dissipating thermal energy, controlling ejecta, and reducing cell-to-cell thermal transfer during catastrophic thermal events – thereby providing both safer and better performing battery systems. The LHS Fill & Flow® system are designed for ease of application and use while providing passive energy absorption, thermal mitigation, homogeneity, and improved battery pack performance.

E.E: What’s the news about new products?

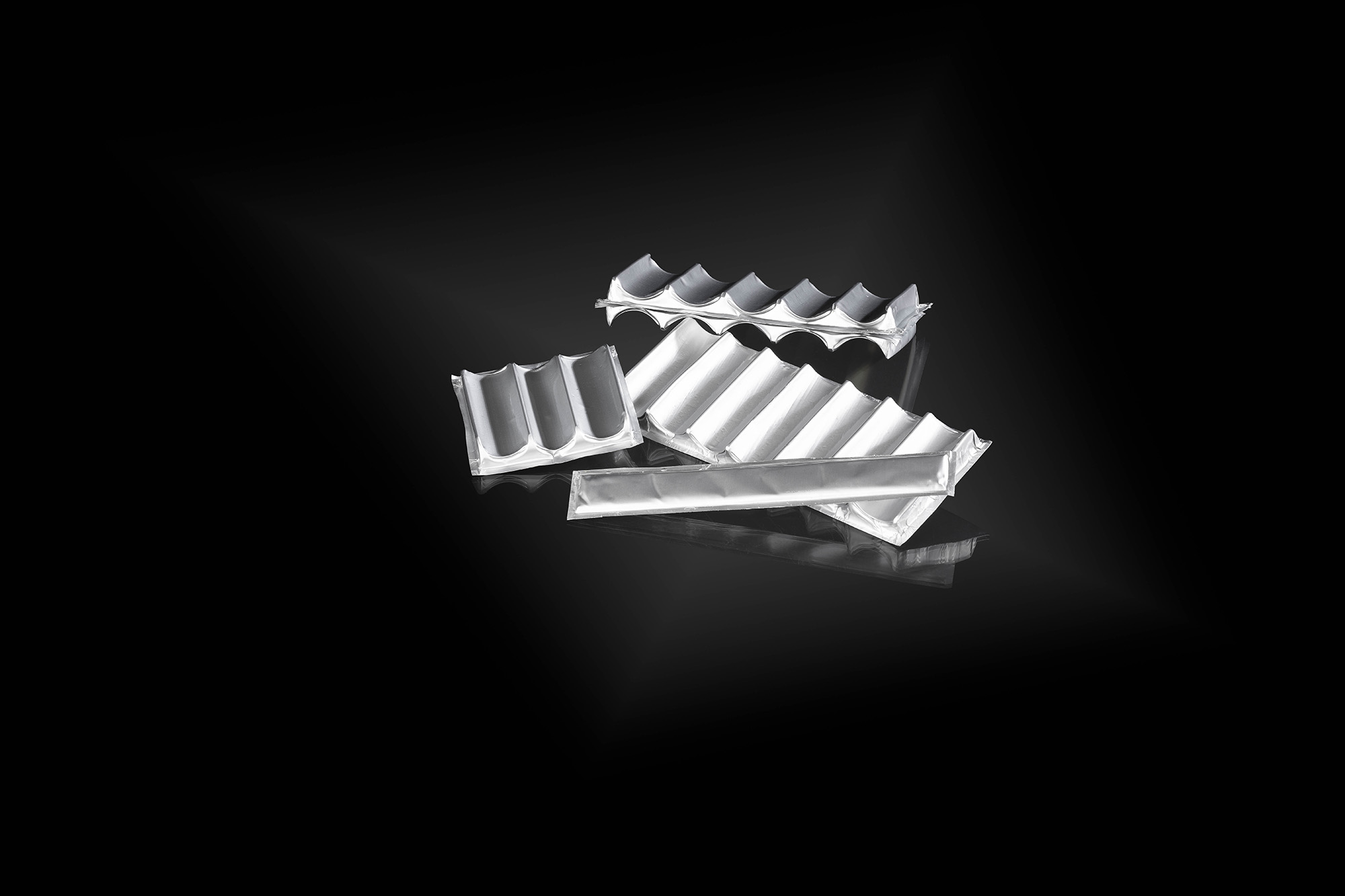

M.H: LHS has many exciting new products that we are offering to the market. We are introducing the XTS Conformable pouch system which allows for drop-in and greater ease of use in various pack designs and cell architectures while providing thermal runaway protection and cell ejecta management with the lowest parasitic mass addition in the industry. The conformable pouch system with increased thermal conductivity also provides unparalleled fire barrier resistance for use in and around pack enclosures.

The new XTS SC1 FR composite material provides UL94-V0 yellow card certified FR performance which allows for incomparable thermal runaway prevention and high temperature thermal absorption in a customized modular structures designed to the customers pack architecture and requirements.

LHS continues to expand the protective temperature ranges of the Fill & Flow product line with our introduction of the F&F-90R. This product has a protective transition temperature in the mid 40-degree Celsius range which complements our higher temperature products.

E.E: At what stage is the market where you are currently active?

M.H: The global Li-ion electrification market is exponentially growing with constant commercial introduction of all types of equipment switching from petroleum powered to electrified systems. LHS has been supplying commercial products to our core market of 2, 3, and 4-wheel e-mobility vehicles, autonomous delivery vehicles, drones, and medical equipment markets. LHS is most active in industries that need high performance, insured safety, and thermal protection from catastrophic thermal events that can damage not only the powered expensive equipment, but also the human user.

E.E: What can you tell us about market trends?

With the increase in energy density and human interactions with Li-ion systems, we are seeing more and more inquires for thermal runaway and thermal barrier protection for safer systems.

E.E: What are the most innovative products marketed?

M.H: The XTS conformable pouch offers a solution to both safety and performance concerns using a unique thermal storage material which absorbs and stores significant thermal energy while also exhibiting excellent flame barrier properties. Applied in an innovative conformable form, this approach can be readily employed across a diverse range of applications and associated battery architectures, extending from small configurations up to larger format systems.

E.E: What estimations do you have for 2022?

M.H: We have targeted and are on track to see a 35+% annual growth in both our XTS® and Fill & Flow® product lines.