Launhardt was founded in 1997 by Erich and Brigitte Launhardt with the technical focus on the polymer extrusion process. Since then, the company has grown significantly and has gained many new business areas. With the joining of Dr. Martin Launhardt and Christian Launhardt in 2019, the industrial 3D-Printing business has been included into the company and since then has been successfully extended.

Easy Engineering: What are the main areas of activity of the company?

LAUNHARDT: Launhardt is focused on the implementation of innovative polymer powders for the powder bed fusion processes such as the selective Lasersintering process (SLS). Within this area we offer an exclusively soft and elastomeric TPU material (Shore A 70), various PP materials and others.

E.E: What’s the news about new products?

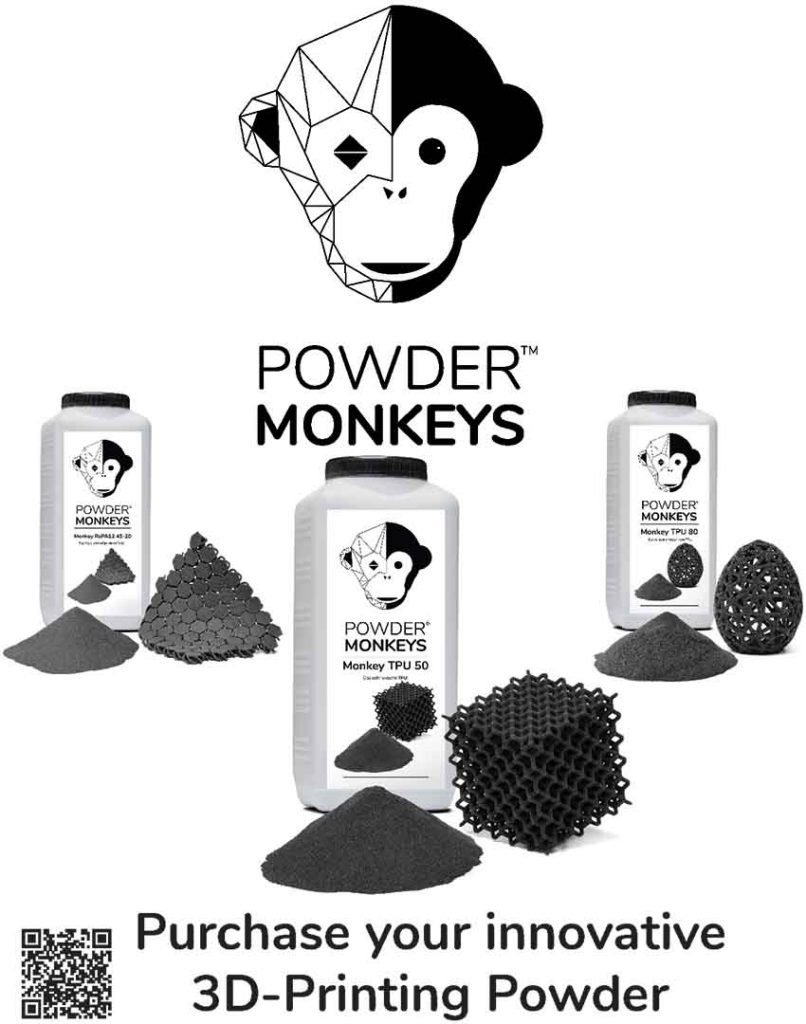

LAUNHARDT: As provider for powder bed fusion materials Launhardt has developed special materials for low power SLS machines such as manufactured by SinterIt and Sintratec. Under the brand of PowderMonkeys™ innovative Powder Materials are provided in user friendly packages.

E.E: What are the ranges of products?

LAUNHARDT: Under the brand of PowderMonkeys™ we offer a very soft elastomeric TPU material which is washable (Monkey TPU 50), a hard elastomeric TPU which is exclusively durable (Monkey TPU 80) and a refurbished PA12 material (Monkey RePA12 45-20) which has been manufactured out of recycled PA12 waste material. As we saw that the SLS process and the typical refreshing rate of 50 weight-% creates vast amounts of waste material we had to take the challenge to make this more ecological. Thus, we have developed a process to refurbish PA12 powders. Furthermore, our TPU powders are 100 % reusable. Only the amount of material taken out as parts needs to be added.

E.E: At what stage is the market where you are currently active?

LAUNHARDT: The distribution of new powder materials in the industrial 3D-printing area is sometimes difficult, because the initial demand for parts out of very flexible TPU materials is not as high as the demand for standard PA12 material. Thus, 3D-Printing factories sometimes hesitate to equip machines with new materials. Subsequently, we started channeling small orders and started manufacturing them at our site. Eventually, besides the powder material we can offer the manufacturing of SLS parts themselves.

E.E: What can you tell us about market trends?

LAUNHARDT: Although at the time many industrial machines are only available with a closed parameter setting, which to a certain degree inhibits the vast implementation of new materials, new machine manufacturers of industrial and consumer machines often go for open systems. This will very much enhance the implementation and usage of new innovative materials for the powder bed fusion processes.

E.E: What are the most innovative products marketed?

LAUNHARDT: For the whole additive manufacturing industry open machines with open access parameters are significantly important for the continuing development of new and innovative powder materials. This is comparable to the injection molding industry, where the machines are fully open to the manufacturers, such that the expertise is and stays with the manufacturers. Closed systems, instead, enforce the typical printer-toner-dependency and restricts innovation.

More and more new and open SLS machines are coming on the market, which opens the development of third-party material manufacturers.

Launhardt is actively developing new materials for open powder bed fusion machines such as an economic and very detailed Polypropylene especially for low laserpowered SLS machines.

E.E: What estimations do you have for 2022?

LAUNHARDT: In 2022 Launhardt will be back at the FormNext in Frankfurt and will have a bunch of new developments both in the industrial as well as in the consumer branch. New developed Powder materials for powder bed fusion processes and new special designs for the additive manufacturing.

There will be a new online shop for distributing the PowderMonkeys SLS Powder and new machines at Launhardt for characterizing new materials on various powder bed fusion machines.

Come visit us at the FormNext 2022 in November in Frankfurt.