LeMur is based in Ala, Northern Italy, a town famous all over Europe for its silk production from late Reinassance to the modern yarn industry. They are specialized in covered stretch yarn products and it is equipped with the most modern technologies for the manufacture of covered yarns. The company is a point of reference in the European stretch yarn market thanks to the high quality of its products, the capability to satisfy every customers’ request and the quick assistance.

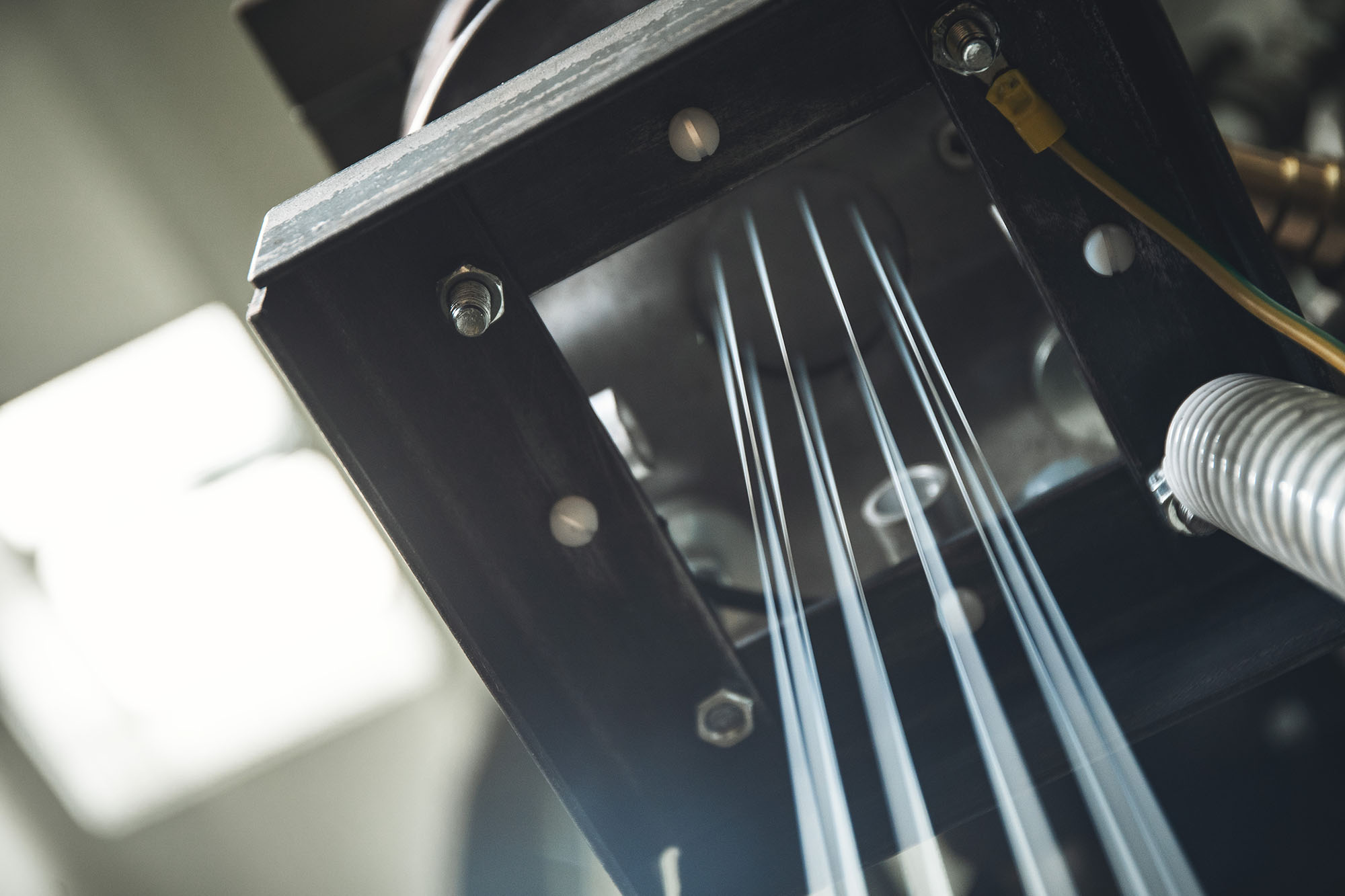

Moreover, LeMur Srl developed in their own R&D lab an innovative spinning technology which leads to the worldwide unique continuous elastic silicone yarn muriel ®.

Interview with Thomas Klotz, General Director of LeMur Srl.

Easy Engineering: What are the main areas of activity of the Company?

Thomas Klotz: Core of LeMur Srl business is the production of single, double as well as air-jet covered spandex yarns for hosiery, seamless, flat & warp knitting, weaving and more. Moreover, in its own Research and Development division LeMur has been able to design and develop a worldwide-patented technology for the spinning of silicone yarn. Thanks to this particular technology, LeMur Srl is the first and only Company able to produce a silicone based elastic yarn with diameter < 1 mm, registered with the trademark muriel ®.

E.E: What’s the new about new products?

T.K: The peculiar properties of silicone such as UV resistance, thermal stability, chemical resistance, biocompatibility and others make possible the use of muriel ® yarn in many different application fields beyond the textile industry, such as medical, light management, food contact, automotive, protective wear and much more.

E.E: What are the ranges of products?

T.K: Following products have been fully industrialized and are available for mass production: muriel ®-med , with excellent biocompatibility for plastic surgery, muriel ®-ray, resistant to UV rays and chemicals, muriel ®-ts with its remarkable thermal behavior, the conductive muriel ®-sensor, developed for smart- and biomedical textiles, the high friction yarn muriel ®-grip, used to create areas with anti-slip features on products like socks, tights and sportswear, and muriel ®-food , the elastic yarn for food contact by high temperature cooking, meeting the highest health standards.

E.E: At what stage is the market where you are currently active?

T.K: The technology that leads to the spinning of muriel ®, the finest continuous elastic silicone yarn in the world, is protected by international patents, so we can proudly say that LeMur Srl is a point of reference and benchmark in this growing business area.

The excellent job done in the past years shows now its results: we receive daily new requests for cooperation and development of new elastic products with Companies from all around the World.

E.E: What can you tell us about market trends?

T.K: Luckily, due to the quality of our products, the traditional yarn covering, core business of the Company, has been constantly growing in the last years, providing LeMur Srl with precious resources that have been reinvested for new technologies and innovative materials, with an eye on sustainability and energy optimization. In the year 2021 we installed a new spinning plant that allowed us to double our production capacity.

E.E: What are the most innovative products marketed?

T.K: Right now, we have open projects involving smart textiles for sport and biomedical applications, as well as aeronautic and aerospace products. Moreover, we are working on technologies allowing us to spin “hybrid” as well as magnetic and luminescent elastic yarns for futuristic applications.

E.E: What estimations do you have for the rest of 2022?

T T.K: he year 2022 is coming to a very positive closing, and we are sure that this growth will not stop in the year 2023. We are constantly working to improve the quality of our products and to ensure the production capability needed to meet 2023 projections.