LINETECHNOLOGY GmbH was founded in 2019 out of a research and development facility of IFE Aufbereitungstechnik GmbH. The company currently has 13 employees at its headquarters in Waidhofen/Ybbs, Austria and is the system provider in the field of waste and composite material processing.

Easy Engineering: What are the main areas of activity of the company?

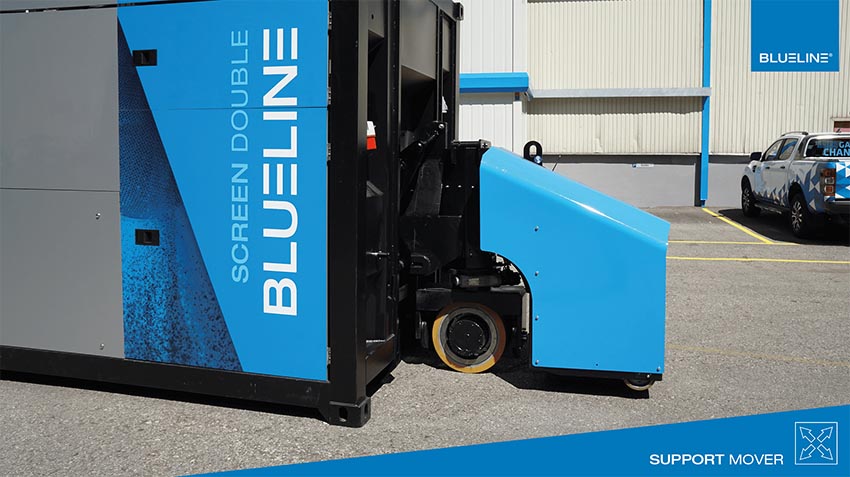

LINETECHNOLOGY: The development, construction, manufacture and sale of modular processing systems under the name BLUELINE. At our state-of-the-art pilot plant, our R&D department carries out material tests for customers and also simulates entire recycling processes.

E.E: What’s the news for 2021 about new products?

LINETECHNOLOGY: We are pleased that we can welcome, additionally to our existing cooperation partners, the companies Westeria GmbH and Andritz AG to the BLUELINE family in the new year. Both will expand the BLUELINE product range in their respective specialty areas with established technology. Westeria will provide bunker and wind sifter technology for BLUELINE, Andritz will supply components in the area of shredding.

E.E: What are the ranges of products?

LINETECHNOLOGY: The great strength of BLUELINE is the wide range of products, which covers almost all process steps of dry mechanical-physical processing. Everything from a single source and coordinated with the meaning of plug-and-play. Our flexible processing modules and the associated IT-based system control enable the customer to react quickly to different input materials or changes in the legal framework. For the customer, this means not only investment security but also the opportunity to try out new activities in the field of processing.

E.E: At what stage is the market where you are currently active?

LINETECHNOLOGY: Many areas of the recycling industry are facing a turning point, away from centralized to decentralized processing systems. In order to meet specified recycling quotas, the depth of the treatment processes must be increased and adapted to the respective input material. This is hardly possible with rigid or stationary systems. It is better to use flexible systems that can be adapted to the input material.

E.E: What can you tell us about market trends?

LINETECHNOLOGY: The trend on the market of recycling plants is clearly veering towards flexible and mobile systems. In addition, customers want more and more information about the current status of their systems, ideally in real time. Exactly these two points were core topics in the development of the BLUELINE and were implemented using the modular container design and an IT-based system control, which reflects all important process parameters in the monitoring.

E.E: What are the most innovative products marketed?

LINETECHNOLOGY: The most innovative product is BLUELINE, of course.

E.E: What estimations do you have for 2021?

LINETECHNOLOGY: I assume that the COVID-19-pandemic will be with us for a while. So, it will have a further impact on the economy and willingness to invest. But when it comes to recycling in particular, there is a lot of catching up to do due to recycling quotas and EU requirements. This, especially in the area of material recycling, can only be achieved with investments in innovative processing technologies.