Loftware is the world’s largest cloud-based Enterprise Labeling and Artwork Management provider, offering an end-to-end labeling solution platform for companies of all sizes.

Interview with Josh Roffman, Marketing & Product Management at Loftware.

Easy Engineering: What are the main areas of activity of the company?

Josh Roffman: We help companies improve accuracy, traceability, and compliance while improving the quality, speed, and efficiency of their labeling. As the leading global provider of Enterprise Labeling and Artwork Management, along with Clinical Trials Labeling and Content Management, Loftware enables supply chain agility, supports evolving regulations, and optimizes business operations for a wide range of industries, including automotive, chemicals, consumer products, electronics, food & beverage, manufacturing, medical device, pharmaceuticals, retail, and apparel.

E.E: What are the ranges of products?

J.R: Whether you have five printers or thousands, looking for cloud or on-premise, we’ve got a labeling solution that fits your business requirements:

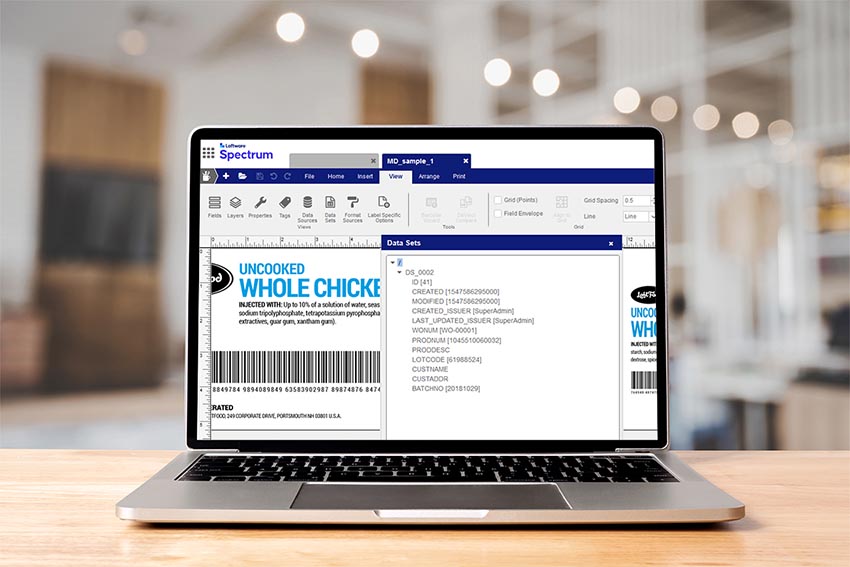

Loftware Spectrum: Loftware Spectrum is the only all-in-one labeling solution to be delivered completely via a browser-based interface. It redefines how enterprises create, manage, and print labels, enabling them to seamlessly implement, deploy, maintain, and scale labeling operations across their entire global network.

Loftware NiceLabel: From label design to print – Loftware NiceLabel offers companies everything they need to manage their labeling process in one, easy-to-use system. Designed for rapid deployments at one site or across multiple locations, it’s an ideal solution for mid-sized or growing businesses.

Loftware Prisym 360: Loftware Prisym 360 delivers innovative content management features which incorporate industry best practice, designed specifically to meet the highly complex regulatory requirements essential for clinical supplies labeling.

Loftware Smartflow: Loftware Smartflow provides businesses with the purpose-built tools needed to manage packaging artwork quickly and efficiently. Smartflow transforms artwork management, streamlining the packaging concept-to-shelf process by implementing accountability and structure.

E.E: What’s the news about new products?

J.R: Loftware Spectrum 4.6 allows customers to drive printer device types from an all-in-one digital solution, enabling businesses to seamlessly deploy, maintain, and scale all their labeling, marking, and coding operations across multiple locations. A key component of Loftware Spectrum 4.6 is added support for all Loftware NiceLabel’s printer drivers.

Loftware NiceLabel 10.2 offers an enhanced view of labeling operations and streamlined printer management. This latest release saves users time, adds control, and expands their ability to manage print resources via the cloud.

Loftware Prisym 360 1.16 introduced a new Clinical Data Connector and Randomization Module designed to increase the efficiency of clinical trial supplies operations while reducing risk and simplifying compliance.

Josh Roffman, Loftware SVP Marketing & Product Management at Loftware.

E.E: What can you tell us about market trends? / What estimations do you have for 2023?

J.R: Our “Top 5 Trends in Labeling & Packaging Artwork for 2023” report, which surveyed nearly 500 professionals within organizations across all major industries and 55 countries, revealed five key trends for the coming year:

#1 The cloud becomes the preferred deployment method

The past few years have brought a rapid upturn in cloud adoption with businesses looking to address “anywhere anytime” connectivity. Now in 2023, the cloud has become the preferred deployment method for business applications and for improving supply chain efficiencies.

Of course, labeling is one area where we are seeing a significant shift. This is because cloud-based labeling empowers organizations to speed deployment and take fast, corrective actions to eliminate bottlenecks, improve collaboration and time to market, and ensure compliance while future-proofing labeling operations.

#2 Traceability increases in importance

Today’s global supply chain requires new levels of visibility as companies add new partners, expand into new regions, and attempt to meet increasing regulatory and customer demands. Ultimately, enabling transparency throughout the supply chain has become a necessity so that companies can ensure quality, safeguard products, protect patients, streamline the location of inventory, and guarantee on-time delivery to market. To do this, businesses are demanding solutions that enable faster reaction times to manage potential recalls and avert risks presented by falsified goods and counterfeit products – all of which could damage brands and threaten customer safety. To manage these threats, businesses must embrace technologies that improve the ability to track and trace products throughout their lifecycle and across the global supply chain.

#3 Supply chain issues continue to impact business

Companies continue to adjust their business strategies as they look to address the state of today’s global supply chain. To survive this shifting business landscape and keep supply chains running smoothly, companies must be prepared to explore alternative ways to optimize business processes and create new efficiencies. More and more corporate leaders recognize the direct connection between labeling and supply chain health. As a result, cloud-based labeling solutions have been put firmly on the radar of organizations that need to extend labeling to new partners and suppliers, accommodate a remote workforce, and ensure the continuous movement of parts and products without delays – both upstream and downstream.

#4 Increased desire for a “one solution prints all” standardized platform

There’s an effort today to move beyond reaction to digital maturity. As part of this digital transformation journey, companies today are seeking an all-in-one labeling solution that can meet the full scope of their requirements for bringing products to market quickly, efficiently, and more competitively. Then there’s increased demand to print on anything from hard or flexible plastic like a water bottle, to a foiled pouch or even a curved surface, or even wood. This has created a desire for a solution that offers integration capabilities to manage output for all devices from thermal label printers, to color inkjet and laser, coding and marking devices, visual inspection systems, serialization solutions, and more. Ultimately, these companies are looking for a “one solution prints all” standardized platform that reduces redundancies, increases efficiencies, and saves time and expense.

#5 Companies adopt composable business model for agility and resiliency

It has become clear that to compete, companies today must be agile and resilient. This means they must be able to adapt to new circumstances and do so quickly. A composable business model is the key to digital transformation in all areas of business and is the future of labeling and artwork management. This model is intended to increase agility and accelerate application development by reusing existing assets and reassembling them in unique ways to satisfy specific user requirements. Today’s cloud-based labeling and artwork management solutions help companies manage speed, agility, and modularity so they can embrace this new composable business approach.