LORSEL GROUP is a brand for a group of companies in the region: LORSEL STROJEVI Ltd, Zagreb, Croatia; LORSEL Ltd., New Belgrade, Serbia; LORSEL BH Ltd., Tešanj, Bosnia and Herzegovina.

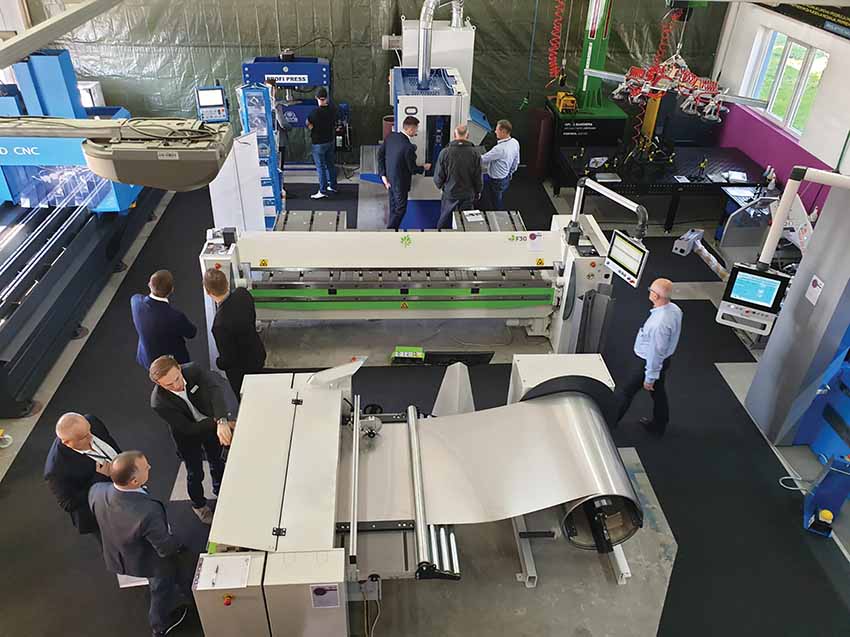

The machines and services offered by LORSEL GROUP are needed by companies engaged in making metal products from sheet metal and tubes processing, making metal structures, boilers, stoves, shelves, industrial equipment, railway vehicles, other various vehicles, catering equipment, machines, various metal appliances, metal casings, devices for various purposes, pipeline production, welding and other companies in the metal industry. Roll bending machines, additive metal printers, bending and punching tools, welding tables and other advance technologies for metal processing.

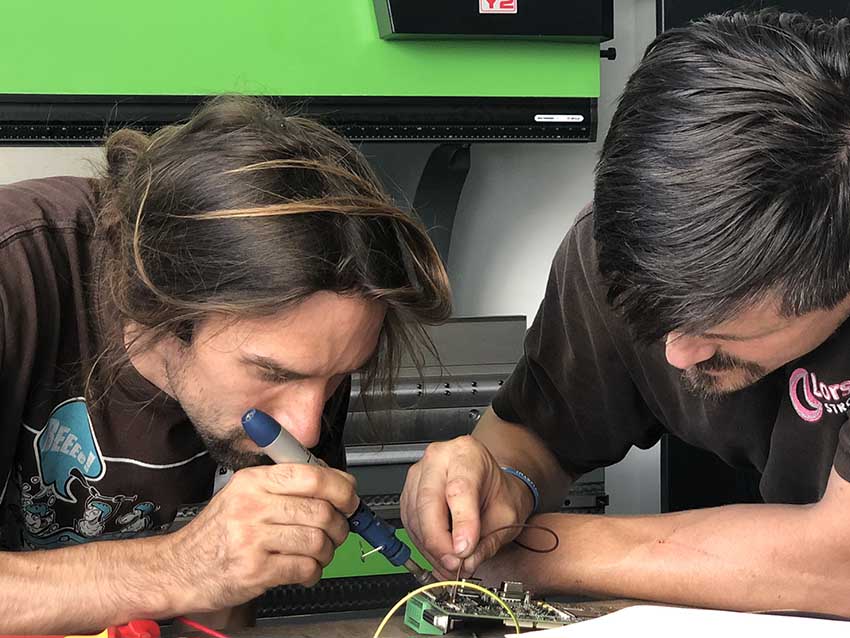

The company also provides services of sheet metal working machines and other industrial equipment. LORSEL’s service team is open to new ideas and react as quickly as possible to the problems that have arisen, as well as to effectively solve them. They enjoy assisting customers in supporting them during the service and maintenance of machines and production facilities.

Easy Engineering: What are the main areas of activity of the company?

LORSEL: The company Lorsel strojevi Ltd, Zagreb is the first company that was founded within Lorsel group. That was in 2011. Since beginning, the company is focused on the service and sales of machines and tools in the metal industry, especially in sheet metal processing. Working with the world’s best companies in their sectors and finding the best technological solutions for our customers has put the company in a leading position in the region.

Our way of working is to solve different problems for our customers. With extensive industry experience, we try to give each customer the best quality ratio to invest in it. Over time, we have developed into a young HI-TECH company with a high level of technical skills.

Whether in the service, selling machines, tools, connecting customers with subcontractors and helping with product development, we always give our best to help solving isuesses a customers productions.

Improving skills and investing in new knowledge is our main focus, or as it is said in Japan – KAIZEN orientation.

E.E: What’s the news about new products?

LORSEL: LORSEL GROUP cooperates with leading companies on the world market that long time ago offered solutions for automation of production processes with the aim of greater efficiency and reduced labor costs. For this reason, we have started to deliver more and more machines with different automation, especially panel benders, laser cutting machines, punching machines that have automatic loading, unloading, and sorting of finished positions. The demand for laser cutting machines is very high, and in 2021 alone we have managed to sell 22 laser machines for metal sheets and pipes, which is an absolute record so far. Some lasers were new, some used. In general, laser cutting machines are increasingly in demand, as they allow for a high-quality, fast, and affordable cut. The number of operations decreases, and the accuracy and quality are very high. In addition, customers invest more in equipping the factory plant, to have the best possible machines and minimize the operator’s influence, again, mainly due to lack of quality manpower.

E.E: What are the ranges of products?

LORSEL: LORSEL GROUP represents world-renowned machine manufacturers by groups: laser cutting machines for plates, tubes and profiles, plasma and oxy-fuel cutting machines, waterjet cutting machines, bending machines for plater, tubes and profiles, roll bending machines, plate and tube grinding machines, punching machines, drilling and tapping machines, welding tables, levelling machines, software, tools, vacuum lifters, different small machines…

Some of the manufacturers we represent are PRIMA POWER, WEBER, FACCIN, FLOW, ARKU, CMA, SOITAAB, SIEGMUND, BLM GROUP, ELEPHANT, WILSON TOOL, ROLLERI, HAEGER, CIDAN, SCANTOOL, SIGMANEST, TAYLOR…

E.E: At what stage is the market where you are currently active?

LORSEL: Last year was the best year ever for many manufacturing companies. So, it is the same with us, which we could not really expect to such an extent following all the pandemic circumstances. In addition, the market remained unpredictable with prices and problems with deliveries of materials and equipment within the agreed deadlines. But there is certainly another trend, which is precisely the large growth that further highlights the issue of lack of qualified human resources. Since most companies achieve significant business growth, the need for people in the market also increases. Labor capacity in the region is not enough, so production facilities mostly employ foreign workers. In the metal industry, in addition to workers from the region who went from country to country for work, workers from Nepal, the Philippines, India, Pakistan and other countries appear. A few years ago, we did not even think that workers from these “distant” countries would be employed in Croatia and region… But the growth of the market continues, so the employment of foreign workers will be increasing.

Domagoj Jendris, DIrector & Owner LORSEL GROUP

E.E: What can you tell us about market trends?

LORSEL: What is happening in our region is primarily the moving of production from Asian countries to the region. Companies from Germany, Italy, Switzerland, Austria, and other EU countries are increasingly choosing subcontractors where they can arrive by car in a day or less, to do some kind of audit, negotiation, agreement. There is a great opportunity for companies in the region to get a lot of jobs and new customers.

Serbia has been able to bring major European and global producers to its country for several years, opening production facilities. Regardless of the conditions they receive or offer, these firms become drivers of an industry to which larger domestic firms as subcontractors. Overall, the economy is growing a lot because of it. Similarly, on a smaller scale, this happens with the market of Bosnia and Herzegovina and Macedonia. Croatia is at the end of this segment. In Croatia, a relatively small number of foreign production companies opened production facilities, and the industry depends on companies with their own products or on those who manage to find customers in foreign countries for which they work directly.

Of course, there are also problems and obstacles around the prices of raw materials and their availability. It is not easy to guarantee complete deliveries on time and keep prices for customers without changes. We hope that this trend will weaken, as many manufacturers find it difficult to do business.

E.E: What are the most innovative products marketed?

LORSEL: There are a lot of interesting technologies from our portfolio that are innovative ones.

Primarily those technologies are:

- Additive laser technology

- Automation of loading, feeding machines, sorting, and storing positions in automated storage – Prima Power Night Train

- Automatic bending machines – servo-electric panel bending machines with different possibilities of loading, automation and connection to other machines in a line – PRIMA POWER

- 3D laser cutting machines – PRIMA POWER

Other types of process automation with robots or line systems for most machines from our portfolio (grinding, levelling, bending, cutting, punching etc.).

Basically, based on the product and the volume of production, we can start with the customer cooperation with the so-called “stand-alone machines”, which can gradually or in one jump switch to fully automated system. We have recognized the manufacturers in the market, with which our customers can grow in the future, and we represent them. We expand our portfolio in connection to market needs and to be able to make our customers leaders.

This is our greatest innovation.

E.E: What estimations do you have for 2022?

LORSEL: In 2022, costs will rise greatly. Utilities, gas, electricity, raw materials… It won’t be easy keeping up with inflation. Manufacturing firms have work to do, but it’s hard to say how much price differences will remain after all the costs increase. This all leads to inevitable wage increases, so I think that manufacturing companies in metal and other industries will have goal to try to do as many as possible, but with as less workers as possible. There will be less and less skilled workers, but also fewer young people who want to work in production.

This is all very bad, because the economy of the region, Europe and the World is based on production. We cannot all live only on services; someone must also make products that are consumed and used in everyday life.

Only if all of us in production will be replaced by ROBOTS and AUTOMATION.

One story for the end:

They say that in the future production companies will have only 2 workers – 1 human and 1 dog. Human will be there to feed the dog, and the dog will be there to not let human touch anything.