MarineShaft A/S is a Danish-based workshop, that specializes in repair of rudder and propeller equipment with full class approval.

Easy Engineering: What are the main areas of activity of the company?

MarineShaft: MarineShaft specializes in cold straightening of all types of shafts and rudder stocks. We have approval from all the leading classification societies for carrying out cold straightening of propeller shafts and rudder stocks. We can straighten shafts of all sizes – from 20 mm to 1,500 mm in diameter using our purpose-built hydraulic press.

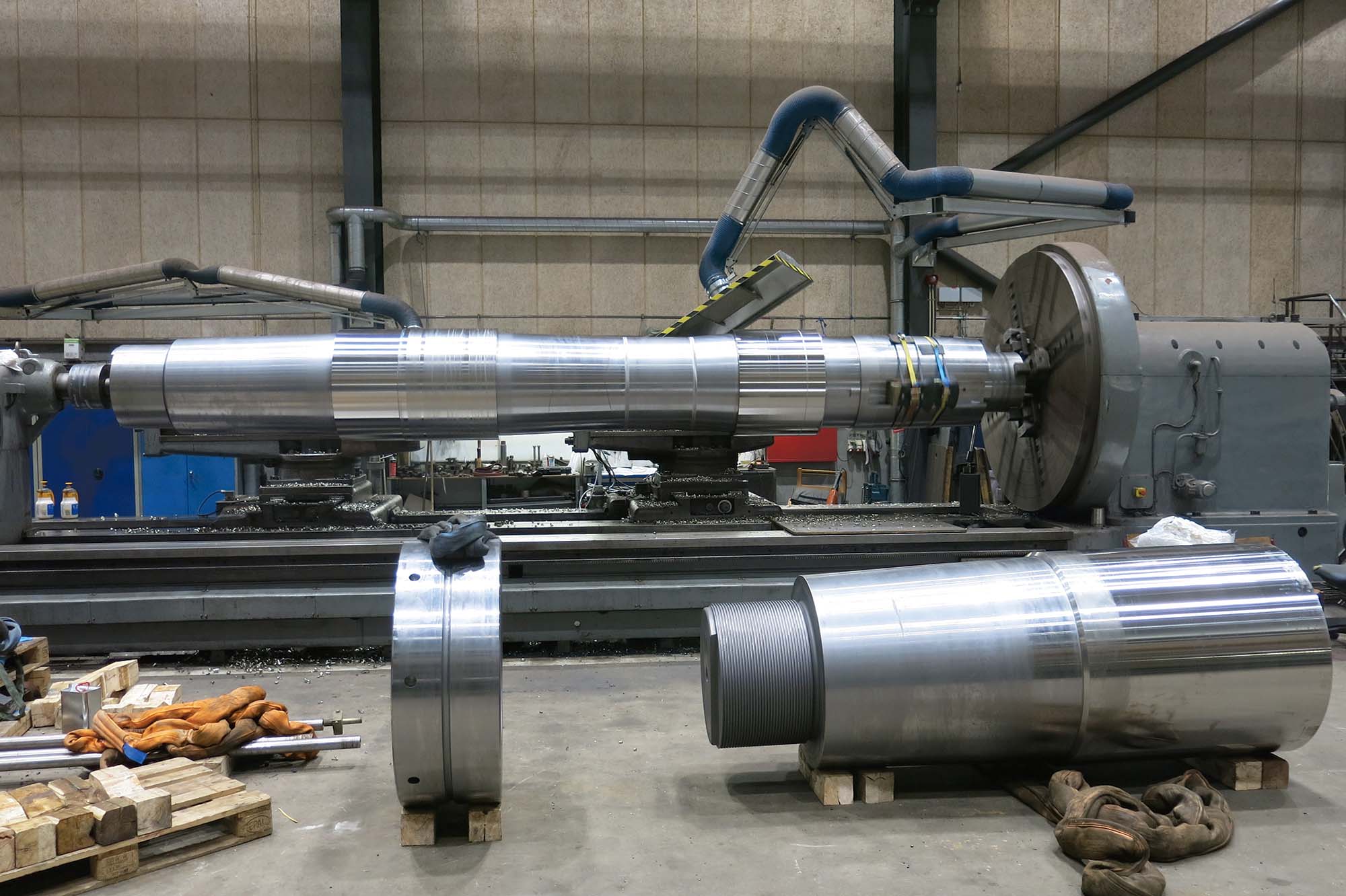

Our workshops in Denmark are fully equipped with a lifting capacity of 200 tons and our biggest lathe capacity is 27 meters. We always have the capacity for urgent repairs, and our skilled service engineers are willing to work around the clock when necessary.

All repairs are done in close cooperation with the classification societies, and a certificate is issued for each repair.

E.E: What’s the news about new products?

MarineShaft: It is of high priority to maintain our stock of raw materials in large dimensions for new manufacturing of shafts and rudder stock. We keep increasing our stock with material for tail shafts, intermediate shafts, etc. It is our goal to provide our customers with the fastest delivery time for new manufacturing. We only stock raw materials of European origin.

An example of a fast manufacturing job previously this year was for one new rudder stock Ø750×6600 mm in material C-Mn steel with two shrunk-on stainless steel sleeves and one rudder pintle Ø900x2585mm in material Mn steel with one shrunk-on stainless steel sleeve.

MarineShaft was able to offer a delivery time of only 15 running days. This short delivery time was only possible because we had the raw material in stock – with class approval and ready to be cut and machined momentarily, the order was received. The order also included the manufacturing of a rudder stock lower hydraulic nut and a new pintle nut.

The new rudder stock was sent by aircraft to a shipyard in the US, where the vessel was docking. MarineShaft service engineer traveled to the location to machine the rudder blade cones and casting.s

E.E: What are the ranges of products?

MarineShaft:

- Cold straightening of shafts and rudder stocks

- Repair/Reconditioning of rudders and rudder arrangements

- Repair/overhaul of propeller equipment

- Repair of propeller blades

- Laser cladding

- Micro welding

- Mobile machining services

- Manufacturing of shafts and rudder stock

E.E: At what stage is the market where you are currently active?

MarineShaft: 2022 started a bit slow, but since early spring the activity has been normal, and right now, we are busy in the workshop with repairs and replacements.

Buying raw materials has become more difficult with longer delivery times due to the world situation, and having a large stock on hand has been an advantage for us.

Our on-site services are slowly coming back to normal level after 2 years of almost no jobs abroad due to the covid pandemic. It seems as if more docking is taking place outside China.

E.E: What can you tell us about market trends?

MarineShaft: The shipping industry has been dealing with many legal requirements such as ballast water treatment, and the emission of Co2. – we think that restoring worn-out items by laser cladding and other restoring processes will become more of a focus as it is both a cost-saving and an environmentally good solution.

E.E: What are the most innovative products marketed?

MarineShaft: Overall, we could say all our services are, due to the quality and fast repair/replacement time. We also believe that Laser cladding will be a growing market.

E.E: What estimations do you have for the rest of 2022?

MarineShaft: The fall has been really busy, and we receive many inquiries. As we are an urgent repair workshop, we never know what the orders will look like 3 weeks from now, but we are optimistic and very satisfied with the order situation as it looks.