MAXIMER LLC has been working on the woodworking equipment market for only 4 years, but for such short time the company managed to acquire loyal partners and establish itself as a manufacturer of high-quality equipment not only in the Ukrainian market, but also in Europe, Russia and Belarus.

During the years of operation, the company has grown from the production of individual woodworking machines to the development of individual automated complete cycle lines for wood processing and the lines for production of pallet boards. The company took part in international exhibitions such as LIGNA (Germany), DREMA (Poland), Woodworking (Belarus) and International Holszmesse (Austria). At DREMA (Poland), SKYWOOD machines were awarded Gold medals for excellent technical characteristics in 2018 and 2019.

The company is constantly designing and developing new machines for the needs of partners. In 2019-2020, the company made some equipment for agricultural sector.

The use of high-quality components, imported from Germany, Italy, Turkey, as well as the relatively low cost of metal and labor in Ukraine, give SKYWOOD machines a competitive price advantage for the equipment with high technical and quality characteristics. Considering the fact that most of the woodworking equipment in Ukrainian sawmills are mainly second-hand European machines, MAXIMER LLC is gradually taking the niche of a Ukrainian manufacturer of equipment of European quality, offering not only machines, but also a guarantee and service.

Easy Engineering: What are the main areas of activity of the company?

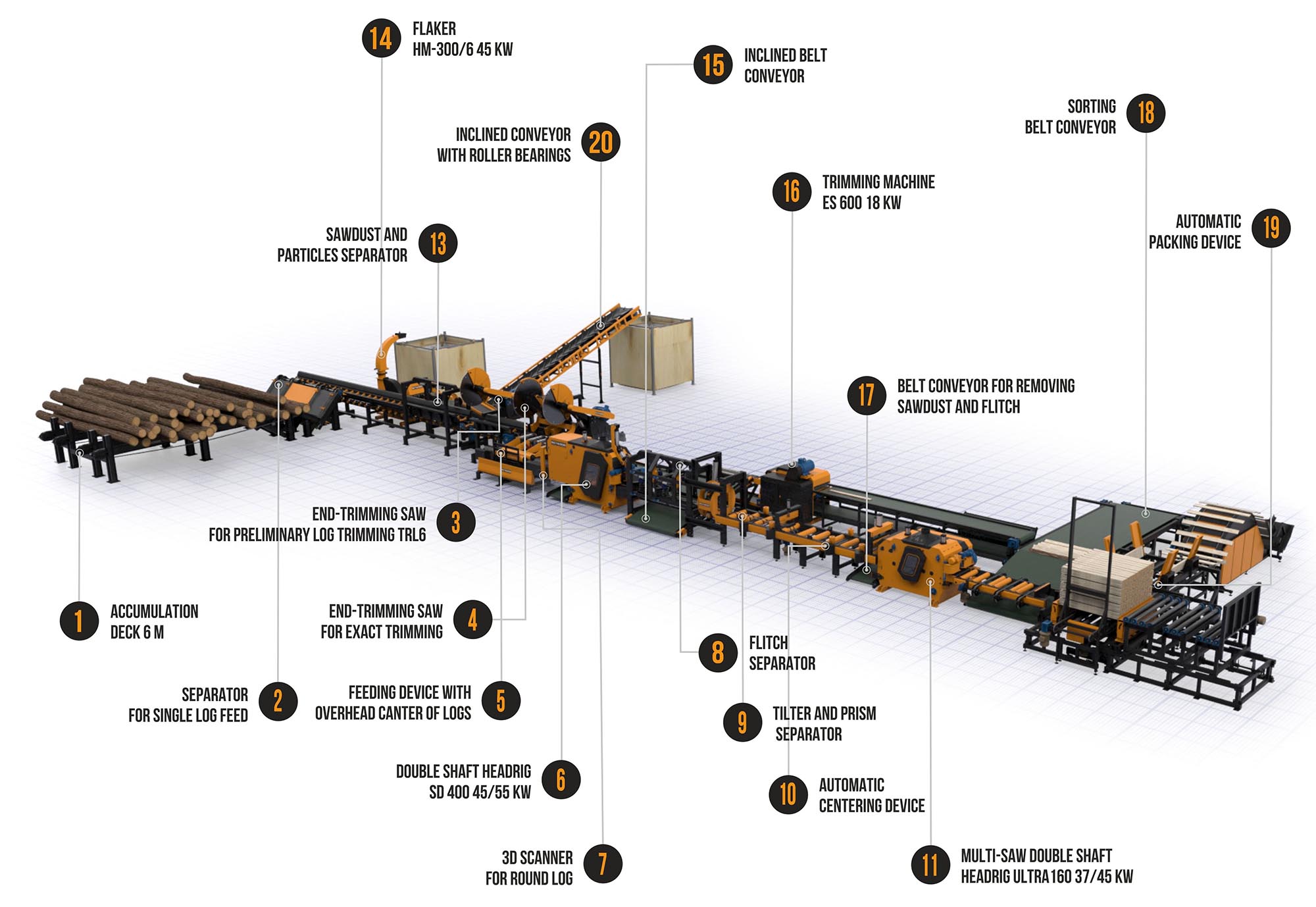

MAXIMER LLC: The main area of activity for the company is the development and creation of woodworking equipment in accordance with the technical requirements of the customer. It can be separate machines for different stages of wood processing, such as a log cutter, multi-saws, edging machines or crosscutting, as well as automatic and semi-automatic full cycle sawmill lines, with minimal involvement of technical personnel in the wood processing, where the client can receive 3 products at once: board, wood chips and sawdust.

The company provides warranty and post-warranty service for the manufactured equipment as well.

E.E: What’s the news for 2020 about new products?

MAXIMER LLC: In 2019 at LIGNA-2019, Hanover, SKYWOOD presented its new development with several patented mechanisms – the Line for the production of pallet boards P900, designed for processing round wood up to 460 mm in diameter. In 2020, the line was upgraded to process round wood up to 550 mm in diameter and with the higher processing capacity per shift.

At the request of our customers, we have developed a debarking machine DB600, which designed to remove bark from logs with a diameter of 100 to 600 mm in the basis of tree.

Another new addition to the company’s product line was the development of sorting lines for round timber and boards. Both lines are designed for sorting logs or planks according to the required size and can work either separately or be integrated into the sawmill line.

This year, MAXIMER LLC has developed an agricultural accompanying equipment – the Twist 600 harrow, which designed for soil cultivation in fields with a significant amount of organic residues, pre-sowing and soil preparation for grains and soil cultivation for winter crops.

The company not only modernizes machines for the needs of the customers, but also develops individual equipment, if necessary.

E.E: What are the ranges of traded products?

MAXIMER LLC: On average, MAXIMER LLC sells 10-12 complete sawmill lines of different designs per year, 15-20 individual wood processing machines for different stages of wood processing, as well as related mechanization such as roller tables, conveyors, separators, wood chips, aspiration systems, etc. Given the growing demand for complete sawmill lines, the company decided to expand its production area and in 2021 increase the equipment manufacturing.

E.E: At what stage is the market where you are currently active?

MAXIMER LLC: 2020 has presented a difficult test for the world’s economy. Ukraine did not stand aside. Along with the dropping of the timber harvesting market, the market for the production of woodworking equipment also subsided. Nevertheless, we would like to note that the downtime, due to quarantine limitations, many sawmills used for the technical re-equipment of their production.

Due to the cancellation or postponement of international exhibitions, where we presented our equipment and new products, the number of new customers dropped by 1/3 compared to 2019, but did not disappear completely. Therefore, in 2020, the main emphasis was placed on working with existing partners. For them, we developed programs to re-equip and modernize existing lines. For our new customers, we have developed the most technically and financially optimal sawing lines.

However, in spite of everything, it is safe to say that the Ukrainian market is still developing and more woodworking equipment manufacturers may soon appear, since the volume of timber harvesting in Ukraine is one of the largest in Europe.

E.E: What can you tell us about market trends?

MAXIMER LLC: Currently, the complete solutions for sawmills are increasingly in demand in the market. That is, if a sawmill is being built from scratch, then the customer prefers to purchase a complete line including an aspiration system, drying kilns, waste disposal solutions, etc. from one manufacturer. Namely, a turnkey sawmill complex is actually being purchased. This is not only beneficial for customers, but also makes the wood processing more efficient from the point of view of a single well-coordinated system of operation of all mechanisms in the chain.

The purchase of one machine or mechanization becomes more and more unprofitable, unless a previously purchased line is being renewed or modernized.

E.E: What are the most innovative products marketed?

MAXIMER LLC: At the end of 2020, due to the high demand, we will present an updated version of our flagship double shaft machine SKYWOOD SD400. The new version is designed for wood from 120 to 450 mm in diameter and a minimum length of 800 mm. We wanted to answer the requests of our partners and created a machine that can cut small logs. We believe that in 2021 this machine will be in demand the most.

E.E: What estimations do you have for 2020?

MAXIMER LLC: The year 2020 was not an easy one in terms of organizing work and observing all security measures under quarantine conditions. But the company managed to adapt to the new working environment. Sales volumes this year have decreased by 1/3 and at the end of the year, we expect sales of about 5 million Euros. However, we are looking optimistic into 2021.