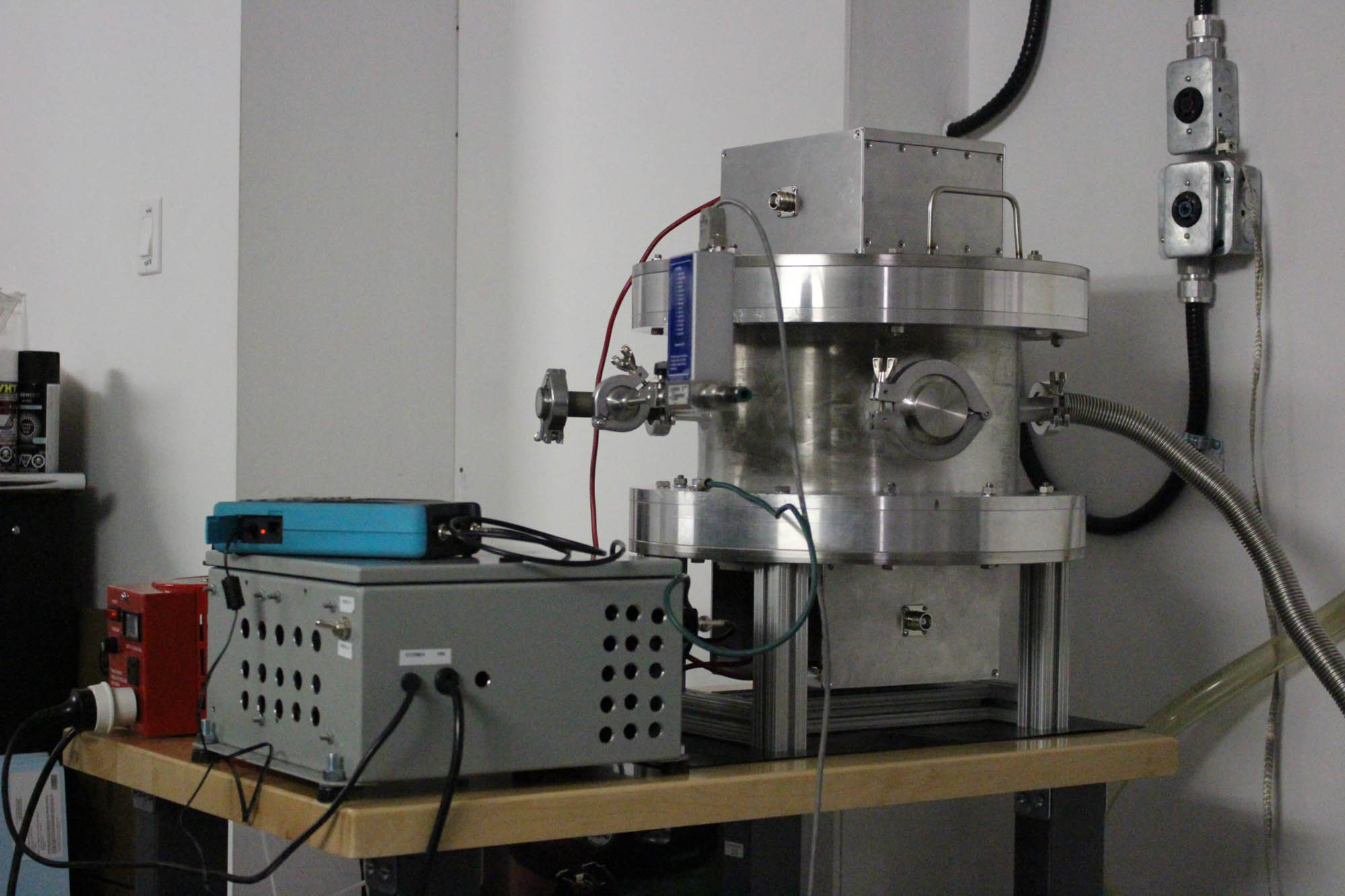

Meaglow Ltd. Was founded in 2009 in Thunder Bay, Ontario, as a semiconductor equipment supply company which had initially hoped to supply universities and colleges with machines for depositing thin films with equipment price tags of $500,000 to $1,000,000. Before the 2008 collapse there had been a buoyant market in this area, however post-2008 there was no recovery of this market. Government grants that allowed universities to buy such equipment were reduced so that this market largely disappeared. However, Meaglow had some innovative attachments to their system and these could be sold separately at prices the market could cope with, in particular, they began selling a new type of patented gas plasma source, one with less oxygen contamination problems than the older legacy sources that were in use at the time.

Since then, the company has sold over 85 plasma sources in 14 different countries, to such customers as the NASA Goddard Flight Center, the NASA Jet Propulsion Laboratories, the US Naval Research Laboratories, Lawrence Berkeley National Laboratories, the National Taiwan University, the Indian Institute of Technology, among many others.

Their Chief Scientist and President visited Australia in 2019 while there were severe fires in that country. In response to this, the company has also been developing water misting anti-pollution products, which they hope to have available soon.

Interview with Dr. K. Scott Butcher, President of Meaglow Ltd.

Easy Engineering: What are the main areas of activity of the company?

K. Scott Butcher: Sort of said that above. We work in the semiconductor equipment supply area. Interestingly, we are located in Thunder Bay, because it is a Canadian rustbelt city. There are many machine shops here, and they have the time to produce our equipment quite quickly, so we do in-house design, assembly and testing, and out source our parts manufacture to local machine shops. We can produce our equipment very quickly because of this model, sometimes within a couple of weeks. Prototypes have been done as quickly as four weeks.

Just to mention, plasma sources are used in semiconductor thin film deposition to make some gas products – such as nitrogen, which is quite inert – more reactive. The sun is a plasma ball, fluorescent lights are plasma sources. A plasma source is basically a gas that is made electrically and chemically active by applying a voltage across it, often under partial vacuum, to tear electrons away from the molecules.

E.E: What’s the news about new products?

K.S.B: We have been developing some antipollution technology, which we hope to have available in 2023. However, in terms of our plasma sources we have developed a very small plasma source for the NASA Goddard Flight Center and are hoping to also provide that as a product in 2023 as well. A pocket plasma source.

E.E: What are the ranges of products?

K.S.B: Introducing a new technology to what has become a conservative market has proven a long haul. Our sales grow steadily every year and we are well established now, but we never really saw our product lines explode into the market, despite obvious advantages over legacy technologies. We have a couple of standard plasma sources we provide now depending on the vacuum systems used, however we still provide a large number of custom made plasma sources. We can make these very quickly because our production model, based on local contract machining, works well in our current location.

E.E: At what stage is the market where you are currently active?

K.S.B: The market has really only been active since about 2007. We sell most of our products to people with atomic layer deposition equipment. That market was very small prior to about 2007, however computer chips have now gotten so small that this method of depositing films, one atomic layer at a time (actually less than that, but that’s a separate story) has become very important for the semiconductor industry. It is now a multibillion dollar industry.

E.E: What can you tell us about market trends?

K.S.B: We export most of our products, with South Korea and the USA being major customers. With Coivd we have seen pauses in sales while things were closed down, followed by waves of orders when things reopen again. Over all the yearly sales have been quite good under Covid, but bumpy. Other international events can also affect sales, American Presidential elections have created order pauses as well. Going forward we are selling into a buoyant market with steady growth, so our sales should continue to grow as well.

E.E: What are the most innovative products marketed?

K.S.B: Ours is the most innovative product in our market. We have patents for hollow cathode gas plasma sources. We are “the” supplier of that product for plasma based thin film deposition. We now produce a third generation product that can be used for large area deposition. We have made plasma sources as large as 12” in diameter to date.

E.E: What estimations do you have for the rest of 2022?

K.S.B: The rest of 2022 is not far away, usually at this time of year we see a bit of a spurt in sales ahead of year end. Should be the same this year.