Mech Solutions is a fast-growing 3D printing company based in Ontario, Canada. The company provides industry-related services such as 3D printing hardware sales, maintenance, and 3D printing service. Furthermore, Mech Solutions has developed its cloud-based AI-empowered 3D printing management platform called ‘Cloud 3D Print’ and launched its product to the global market in 2022 Q4.

The company offers some smart solutions such as AI-based spaghetti failure detection, 3D printing project management, and cloud-slicing through its cloud-based platform and is working on the development of the next-generation AI-empowered Mech 3D printers. Mech Solutions left a significant impact on the market after the joint contribution of its highly expert team and its associated R&D partners at various institutes. It received $1.5M in funds for the “Research and Development” (R&D) project from the Canadian Government. Moreover, it continuously strives to indulge with other organizations for continuous development, growth, and collaboration.

Interview with Haoliang Zhou, CEO of Mech Solutions.

Easy Engineering: What are the main areas of activity of the company?

Haoliang Zhou: Mech Solutions is currently involved in the research and development of AI and deep learning in 3D printing failure detection. It is working with the University of Toronto and Ontario Technology University for further R&D in the product. The concept of artificial intelligence (AI) has become increasingly prevalent in the industry, but there is still insufficient understanding of what AI can exactly do for manufacturing companies like Mech Solutions.

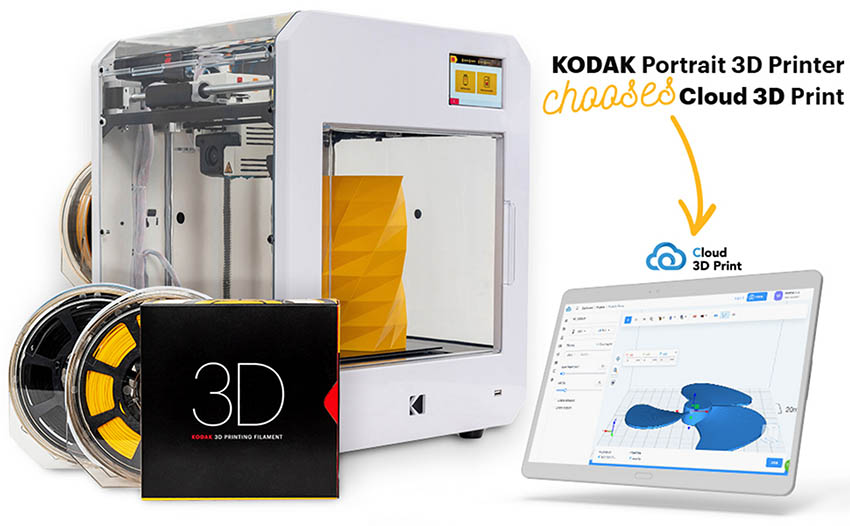

To enhance the reach of its cutting-edge product, Cloud3DPrint, Mech Solutions has collaborated with numerous 3D printer manufacturers around the world for the integration of Cloud3DPrint into their hardware. The main aim of this collaboration is to build the next generation of cloud-controlled 3D printers.

Currently, the company is actively participating in different global exhibitions to gain maximum exposure and collaboration opportunities. As every start-up needs marketing of its product and services to the global market in the initial phase. To develop in this area Mech Solutions continuously involves in such exhibitions for further development and growth opportunities.

E.E: What’s the news about new products?

H.Z: The development of a smart 3D printing ecosystem is one of the major goals of Mech Solutions. Upon launching its easy-to-use and appealing cloud 3D printing management platform Mech Solutions has maximized user efficiency and is continuously putting more effort into providing solutions. The management of all the 3D printing jobs via Cloud3DPrint and its AI-integrated remote feature has revolutionized the manufacturing world. Initially, spaghetti failure was one of the major hurdles in rapid prototyping. But its integration of AI and image processing technique in 3D printing have abruptly enhanced the fabrication process.

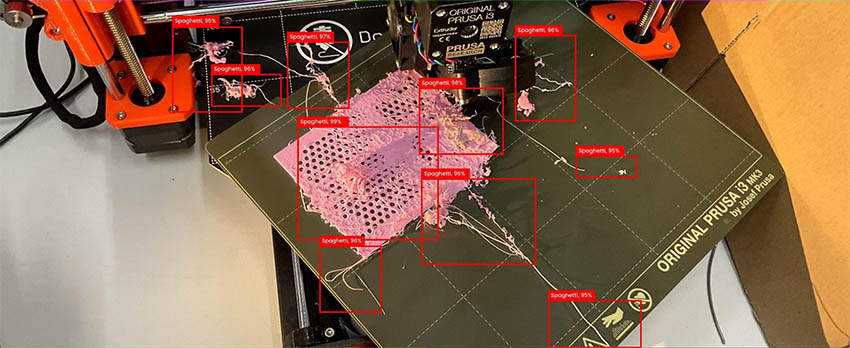

Moreover, the remote failure detection via camera feature of Cloud3DPrint further adds more value to the user experience. A red frame is drawn in the 3D printing failure area and the user is alerted through a beep on their smartphone through an email or notification. One of the major product development goals of Mech Solution is to develop its own IOS and Android app that will add significant value to customer ease and business development. The utilization of our expertise in 3D printing helps the company to reduce costs and improve the efficiency of CAD/CAM.

Our solutions can let one person monitor hundreds of 3D printers and manage all the data on the cloud. At present, Mech Solutions is using a powerful module that has high accuracy, fast response, and a very low false positive rate. It can be said that no one in the world can be more accurate in AI-based spaghetti failure detection than Mech Solutions at the moment.

E.E: What are the ranges of products?

H.Z: Initially, Mech Solutions started as a 3D printing services company. But as time passed the team experienced manufacturing downtime in the current 3D printing setups. The manufacturing downtimes were mainly because of downloading the slicing software repeatedly, losing CAD files, and babysitting the slow 3D printing process. After closely analyzing the manufacturing workflow the team of Mech Solutions was able to find a way out with its dash of expertise, a sprinkle of persistence, and a bucket of passion for 3D printing. In this way, the Cloud 3D print got its birth.

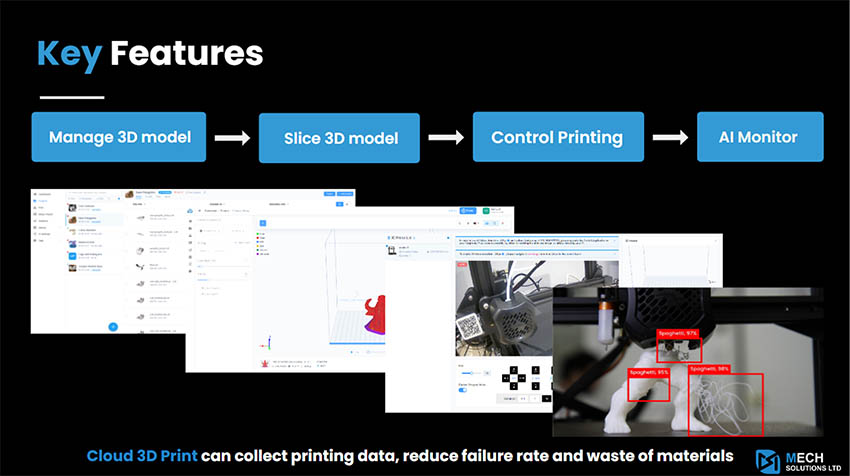

Currently, Cloud3DPrint includes the following features:

Cloud-based Project management: Whatever the application is, Cloud 3D Print will help the user efficiently manage their 3D printing projects. The project management software allows the user to sit back and relax as all aspects of the projects are under control.

Remote control and monitoring: Watching a 3D printer operate is mesmerizing yet painfully slow. Cloud 3D print offers advanced remote monitoring and control features for 3D printers. Cloud monitoring allows the user to view the real-time progress of their jobs with snapshot features and the ability to record live videos.

Cloud storage: Managing the 3D printing workflow in cloud storage is easier than ever. The storage feature centralizes the users’ 3D printing and streamlines their data while keeping it safe. Our online cloud storage system automatically organizes their data according to their personal preferences.

AI Failure detection: Cloud 3D Print monitors through AI-Integrated cameras around the 3D printers. The powerful calculation engine, backed by a robust deep learning model, is programmed to detect general printing errors such as spaghetti failure.

Online slicing: When a user operates a 3D printing job, he will get a set of simple yet powerful tools to explore, analyze and slice 3D models, and send them to 3D printers – all without jumping from one environment to another. That’s what Cloud 3D Print provides: an integrated user experience for handlings 3D models and 3D printers on the cloud.

E.E: At what stage is the market where you are currently active?

H.Z: After years of market cultivation, the 3D printing industry laid a certain market foundation in the manufacturing industry. In 2030, it will become a market worth hundreds of billions. Based on the Delphi study of Additive Manufacturing for economic and social implications for 2030 shows that a significant amount of small and medium enterprises will share industry-specific additive manufacturing production to achieve higher machine utilization and quality assessment. Mech Solutions believe that in 2030 conventional measures of “time to market”, “product life cycle” and “ramp-up” will have diminished as the novel digital products will be in a continuous beta stage and be subjected to frequent design iterations and constant modifications.

At present, Mech Solution has optimized its product development strategy to address the gap in software services for consumer-grade 3D printers. The company is continuously striving to enhance the 3D printing experience for enthusiasts through the implementation of online collaboration and management features. This product offering is expected to attract a wider consumer demographic, including those who are less technically proficient, to explore and adopt 3D printing technology. By doing so, Mech Solution aims to drive the advancement of the next generation of 3D printers.

The entire industry is still in the early days of the market, just like when smartphones didn’t even exist. For example, the underlying drivers of 3D printing are still not standardized as other conventional manufacturing machinery is standardized by ASME and ISO, the printing failure rate is high as not much data has been collected yet, the 3D printing is still slow due to lack of availability of efficient lead screws, motors, and assemblies. Moreover, the software services for 3D printing are currently still in the developmental phase.

Due to the exponential growth in the demand for 3D printing, Mech Solutions aims to develop such products that can meet the pain points of users in the market around the world. The efficiency of Mech Solutions in providing meeting these pain points will lead to a high-speed growth of the company in the next 3-5 years. This is the reason why Mech Solutions claims to become the industry leader in the next 3 years.

Mech Solutions believe that 3D printing is an essential field for the upgradation of national industries. The market development in recent years shows a sharp increase in the market trend for 3D printing in China, driven by the rise in demand for rapid prototyping and production across several sectors, including consumer products, healthcare, aerospace, and automotive. In addition to investing in and sponsoring research and development, the Chinese government has supported the advancement of 3D printing technology.

E.E: What can you tell us about market trends?

H.Z: The 3D printing industry is expected to experience significant growth over the next decade, with a projected market value of US$16.7 billion in 2022 and US$82.1 billion by 2030. This represents a compound annual growth rate of 23.7%, highlighting the increasing demand for 3D printing technology. The 3D printing market can be segmented into three main categories: software, hardware, and services. Of these, the software currently holds the largest share of the market, accounting for 35.7%. In 2022, the software market is estimated to reach US$6 billion and is expected to grow to US$25 billion by 2030.

Due to its maturity and the wide range of capabilities, it provides, 3D printing is positioned to become a dominating technology shortly across several sectors. 3D printing is an important factor of Industry 4.0 because automation allows it possible to produce complicated shapes, reducing inventory, manufacturing on demand, promoting local production, and shortening supply chains. According to research, the remarkable track record of 3D printing will fuel its anticipated expansion, and is expected to produce $2 trillion in components and finished goods by 2030.

The software services of 3D printing are mainly divided into 3D model design, scanning, 3D printing process control, post-processing, and other categories. The Mech Solutions product belongs to 3D printing process control software. At present, the entire market has just started to grow, and the annual growth rate is expected to reach 25% in the next few years.

E.E: What are the most innovative products marketed?

H.Z: The goal of Cloud 3D Print is to design and build a next-generation smart 3D printer that will be integrated with our AI-powered printing management platform (Cloud 3D Print). The innovative scope in the AI part is to investigate the variable methods to achieve failure detection, including machine learning, such as recurrent neural networks (RNN), and deep learning, such as Convolutional Neural Networks (CNN).

Speaking technically, the failure pattern itself is pretty tiny and complicated, therefore, it will require us to train different models and develop an algorithm to obtain high accuracy while minimizing the false positive. Various reasons lead to false positives in our AI detection. Initially, every model is trained on a limited and biased dataset due to a lack of exposure to real-world scenarios. It leads to the over-fitting of the data which results in false positives. Poor quality data such as missing values and incorrect values or irrelevant features can also result in false positives in AI predictions. It’s essential to be aware of these possible causes of false positives and to put mitigation strategies in place, including employing a variety of representative training data, assessing and fine-tuning algorithms, and putting transparency and fairness standards in place.

In light of the above issues, Mech Solutions also aims to develop an algorithm to post-process the AI results and improve the reliability on the server side. In this area, Mech Solutions have applied for two patents regarding the AI algorithm. In this field, we only have one competitor called The Spaghettis Detective. Mech Solutions claims that its algorithm is more accurate than the other competitor as it can detect more patterns which lead to greater accuracy. Mech Solutions confidently have been leading in this area for at least 2 years.

E.E: What estimations do you have for 2023?

H.Z: Mech Solutions follows the concept of Industry 4.0 by developing its products according to new technologies, manufacturing factors, and workforce organization. Cloud3D Print aims to change the production process by creating a highly efficient production system that reduces production costs and improves product manufacturing efficiency. The manufacturing industries are transformed from mechanization to digitalization with the help of Information and Communication Technology (ICT).

Now, the advancement of ICT and the Internet of Things has enabled smart manufacturing or Industry 4.0. Following the standards of Industry 4.0, Mech Solutions aims to embed Cloud 3D Print into 3D printers or Internet of Things (IoT) accessories to provide an all-in-one cloud solution for 3D printer manufacturers and end users. Back in 2022, when the product launched, Mech Solutions remained in close association with the 3D printers and IoT manufacturers to deliver the product to manufacturers. With all those efforts, Mech Solutions obtained 1000 users and got a lot of positive feedback.

In 2023, Mech Solutions aims to sign contracts with five KA in order to obtain more than 9500 SaaS subscriptions. Upon successfully achieving this target, Mech Solutions will build brand awareness in the industry by setting out some essential brand development strategies. Mech Solutions also aims to build technology barriers with AI and data management. After 2023, Mech Solutions aims to develop quickly by forming stand cloud solutions in the industry and supply more than 10 KA manufacturers to obtain 100,000 +SaaS subscriptions by 2025. Mech Solutions hopes to occupy a 12% market share in three years and become the leader of the market by successfully utilizing such efficient practices.