Easy Engineering: A brief description of the company and its activities.

MICROCUT: Microcut is the reference address for high-precision finishing of small bores.

With passion we develop machines and tools for the efficient finishing of small bores with highest quality requirements for the diameter range from 0.015 mm – 8 mm. As a service we offer Microcut contract honing.

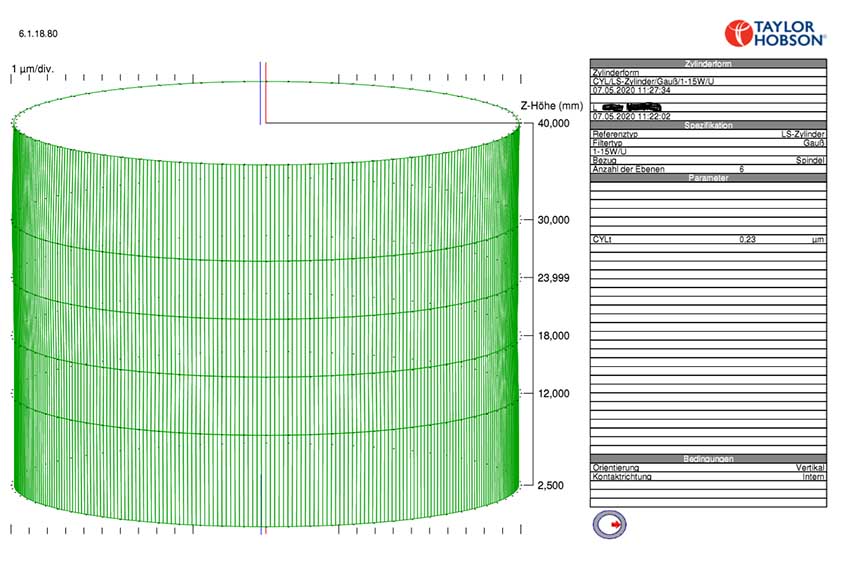

The Microcut Honing System for small bores is an easily controllable and robust process and guarantees minimum dispersion of shape accuracy, surface quality and dimensional accuracy.

The Microcut Honing System, developed specifically for small bores, has outstanding technical and economic advantages over established processes such as internal cylindrical grinding and conventional honing.

In 2019 we proudly presented the sonic-honing technology, which combines highest precision AND productivity. With this development stage, the cutting performance could be increased by factor 4, the surface roughness improved and the tool life extended.

With the Honing Module MH©cut we bring our 4.0 technology directly onto a machine tool, such as a hard turning lathe, thus enabling complete finishing in one clamping.

In the course of the general miniaturization of components, the Microcut Honing System offers solutions for small bores, where established methods reach their limits due to their principles.

An ever-increasing demand for quality, with high cost pressure, can additionally favor a process change to the Microcut Honing System.

Low tool costs per bore as well as low space and energy requirements of the systems underline the sustainable customer benefit of our technology.

The process is suitable for small quantities, e.g. in tool and mould making, but also for large series in the automotive industry. Our machines are modular and scalable.

Due to the easily reproducible, exceptionally good shape accuracy, the demand for Microcut machines for larger diameters is also increasing. The advantages are particularly evident in interrupted main bores with releases and cross bores, such as in hydraulic control components.

E.E: What are the main areas of activity of the company?

MICROCUT: As mentioned at the beginning, we are active as a machine builder and as a service provider in the field of contract manufacturing.

The main industries we serve are tool and mould making, aerospace, automotive, medical technology and the watchmaking industry.

E.E: What’s the news for 2021 about new products?

MICROCUT: Since we launched our SONIC-HONING technology in late 2019 early 2020, we will focus on implementing this technology for our customers in 2021. In 2022, we will launch our UniBore 900 machine line and increase our machining diameters from 8mm to 15mm.

E.E: What are the ranges of products?

MICROCUT: Our machine program fully covers requirements for small series in the mould and tool bar as well as high volumes in the automotive sector. With our new UniBore 900 generation, we have once again increased our focus on fully automated production.

For all areas where the acquisition of a new machine is not yet profitable, we offer contract manufacturing.

Here we can produce series of 1 – 1 million.

E.E: At what stage is the market where you are currently active?

MICROCUT: It is quite complex to describe the current market situation, due to our diverse areas of application in the various markets. Some markets have collapsed due to the COVID-19 pandemic while others have experienced massive growth.

In general, however, we can say that our markets are on the move and we are satisfied with the current order situation.

E.E: What can you tell us about market trends?

MICROCUT: Although we will expand our portfolio and be able to process larger diameters of up to 15mm in the future.

It is becoming apparent that the demand for high-precision small bores for diameters between Ø 0.5 mm to Ø rah2.5 mm is growing steadily.

Everything in the tool and mould making sector benefits from ultra-precise production with Microcut Honing technology.

In the automotive sector, the internal combustion engine is declining, but we can still look forward to sufficient orders here.

It remains exciting to follow the developments in the automotive sector. In addition to the electric drive for passenger transport, other concepts for long-distance and freight transport are in the starting blocks and we look forward to playing a key role with our technology in this area as well.

E.E: What are the most innovative products marketed?

MICROCUT: Having already rolled out a highly innovative technology with SONIC honing, currently we are guided by what is happening in the market in general and make sure that we continue to be among the first movers in the field of Industry 4.0. Fully autonomous production, implementation of production data in the cloud and the complete networking of our machines will certainly continue to play an important role in the area of high production.

E.E: What estimations do you have for 2021?

MICROCUT: We will close 2021 on a positive note, hoping to win many more new customers by the end of the year.

For 2022, we are looking forward to making our technology accessible to even more people and we are finally looking forward to participating in trade fairs again.

The first one we will attend is the Grinding Hub in Stuttgart in 2022.