Easy Engineering: A brief description of the company and its activities.

MIG-O-MAT: Since 1972, MIG-O-MAT has been developed forward-looking welding technologies and produces the corresponding appliances and plants in the fields of plasma welding and microflame soldering. Just with the plasma technology in connection with automatizador partly-automatized surroundings, especially safe and economic welding processes are possible. With our experience of decades and our mature and more and more improved products, we are able to offer our customers an optimal support starting with the advices regarding the design up to the company during the production process. If requested, we produce sample series until a trouble-free operation process is secured.

As the appliances are enveloped and produced by ourselves, we are able to react with a maximum of flexibility to the existing requirements and conditions and so, we reach tailor-made solutions with regard to the application. Again and again, our customers are enthusiastic – as especially in cases of a difficult problem definition, by which a conventional welding technology is not offering satisfying results, we convince by effectiveness, economy and process security. Not for nothing, MIG-O-MAT is belonging to the market leaders in the fields of plasma welding and microflame soldering and serves customers worldwide, who want to play safe with the high quality of the MIG-O-MAT-products „Made in Germany“. MIG-O-MAT is part of the worldwide acting UNIWELD Group, producing i. a. the high-performance welding units for the aviation and aerospace sector, the installation of power stations, steel and container production and for the large space tube production.

E.E: What are the main areas of activity of the company?

MIG-O-MAT: Main areas are plasma welding and micro flame soldering.

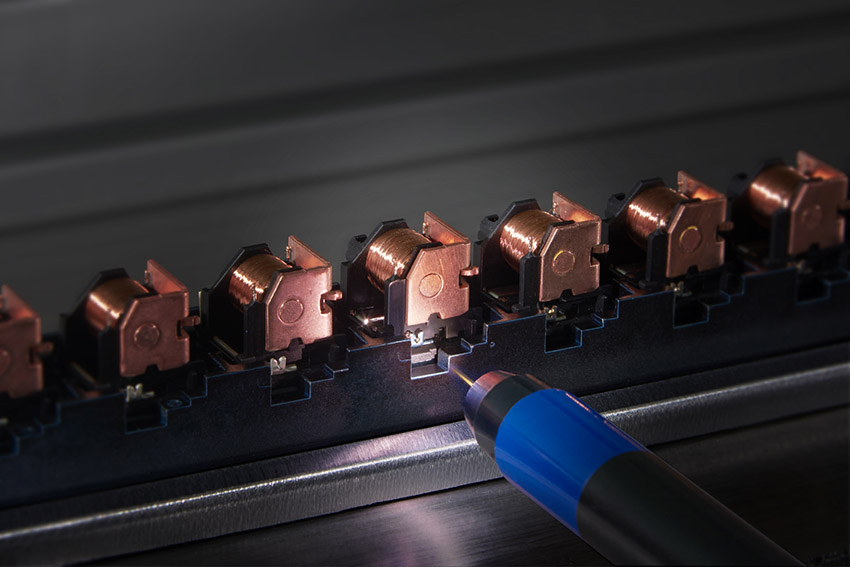

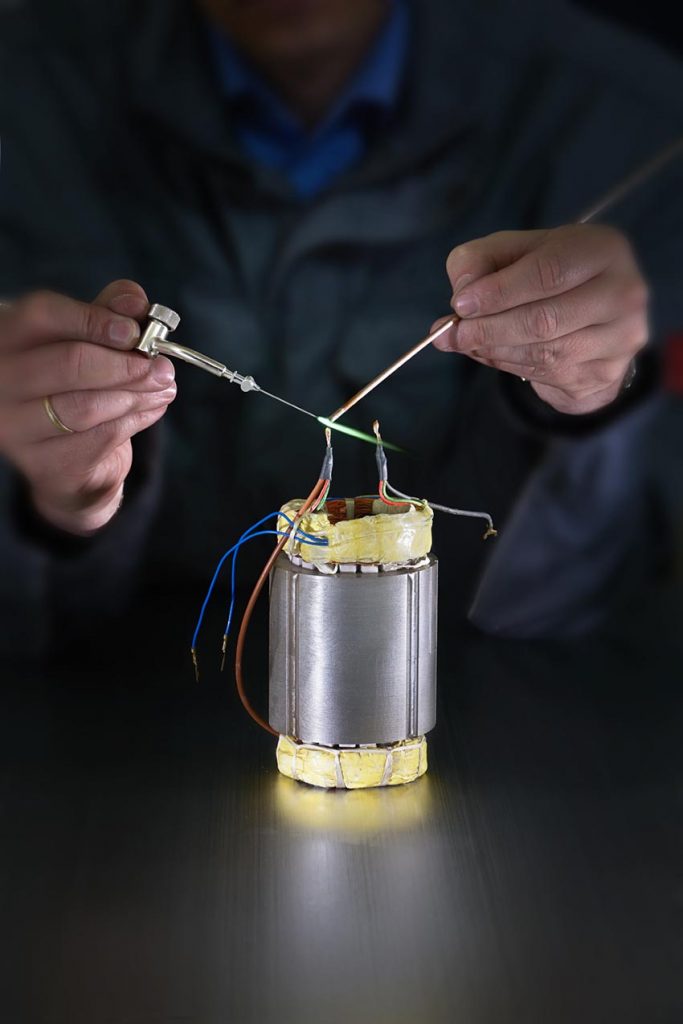

Plasma welding is used in several fields, for welding very thin material (0.1mm) in the field of production of bellows for automotive, in the middle range for production of turbo charges up to the range with material thickness of 3-10mm for welding stainless steel tanks and plates. Micro flame soldering is used where a concentrated, small reproducible flame is used, starting for crafts like gold smith, dental labs up to industry like production of electromotors, electronic parts or cable assembly.

E.E: What’s the news for 2021 about new products?

MIG-O-MAT: The trend continues towards the automation of processes, for which MIG-O-MAT offers solutions for the integration of welding and manufacturing systems into the customer’s structure (Industry 4.0).

E.E: What are the ranges of products?

MIG-O-MAT: Micro flame soldering machines which produces oxygen and hydrogen by splitting of water (green energy) and plasma welding, which is a special welding process for high requirements in a big range of products, component weights of 1g – 20t.

E.E: What can you tell us about market trends?

MIG-O-MAT: The markets are changing increasingly. Even if a lot is currently being produced for internal combustion engines, the trend is towards production technologies for electric cars. Both micro plasma welding (welding of hairpins) and microflame soldering for connecting cables offer an interesting manufacturing technology, which, however, is unknown in many areas.

E.E: What are the most innovative products marketed?

MIG-O-MAT: All products are innovative, although the technology behind them has been known for decades 😊. As an example, microflame soldering, which uses electrolysis to generate oxyhydrogen from water (hydrogen-oxygen mixture). The first devices were developed by MIG-O-MAT in 1972 and the technology is brand new again today due to the trend towards hydrogen as a future energy supplier.

E.E: What estimations do you have for 2021?

MIG-O-MAT: Our goal for 2021 is to make both technologies better known, especially in the field of electromobility. For this purpose, various trade fairs are visited (e.g. Coiltech) and application reports are created.