Lj. Ristic is recognized as one of the pioneers of MEMS (Micro-Electro-Mechanical-Systems) Technology, having contributed to multiple groundbreaking advancements in the field. He also served as the editor for the book ‘Sensor Technology and Devices’, widely recognized as the first book that shed light on MEMS technology and micromachining techniques, highlighting the essential role this technology would play in developing sensors and actuators. Currently, he holds the position of Chief of Business Development and Strategy at Mirrorcle Technologies.

Interview with Lj. Ristic, Chief of Business Development and Strategy at Mirrorcle Technologies.

Easy Engineering: What is MEMS technology and how are MEMS Mirrors related to it?

Lj Ristic: MEMS technology is a derivative of integrated circuit technology used to make small micromechanical structures from silicon. These structures are membranes, beams, cantilever, springs, or any combination of them. They move, they bend, they tilt, they oscillate, and doing so, they convert electromechanical or optical signal into useful electrical signal, subsequently processed in analog or digital domain.

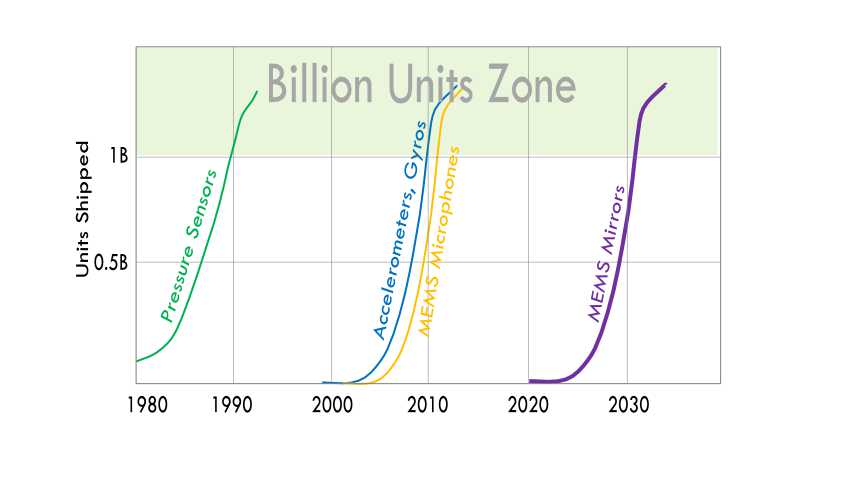

The basic MEMS structures are used to make MEMS Products; MEMS Mirrors are just one type of MEMS products. Other products include pressure sensors, accelerometers, gyros, microphones, inkjet printheads, RF and timing devices, and many others.

E.E: What does the supply chain look like and who are the big players in MEMS Industry?

L.R: The MEMS Industry supply chain can be divided into front-end and back-end. The front-end supply chain focuses on silicon, leveraging mature IC-process steps alongside some specific steps for making MEMS structures. The technology on the front-end is always several generations behind the leading-edge IC nodes, thus it benefits from maturity and lower cost of manufacturing. Today, Si-MEMS production primarily utilizes 6” and 8” wafers. Most of the MEMS companies use foundry services, while only big players can afford internal manufacturing capabilities.

The back-end supply chain focuses on assembly often utilizing diverse packaging schemes tailored to the product application. Typically, packaging for MEMS products is more complex than packaging for standard ICs. Most of MEMS companies rely on CMs for back-end processing.

The big players in the MEMS industry are Bosch, Broadcom, STM, TDK, Qualcomm, NXP, and TI, followed by many companies with smaller product portfolios. The newcomers in the MEMS industry do not have a choice but to rely on MEMS foundries and CMs for volume manufacturing.

E.E: Can you give us a brief description of your company?

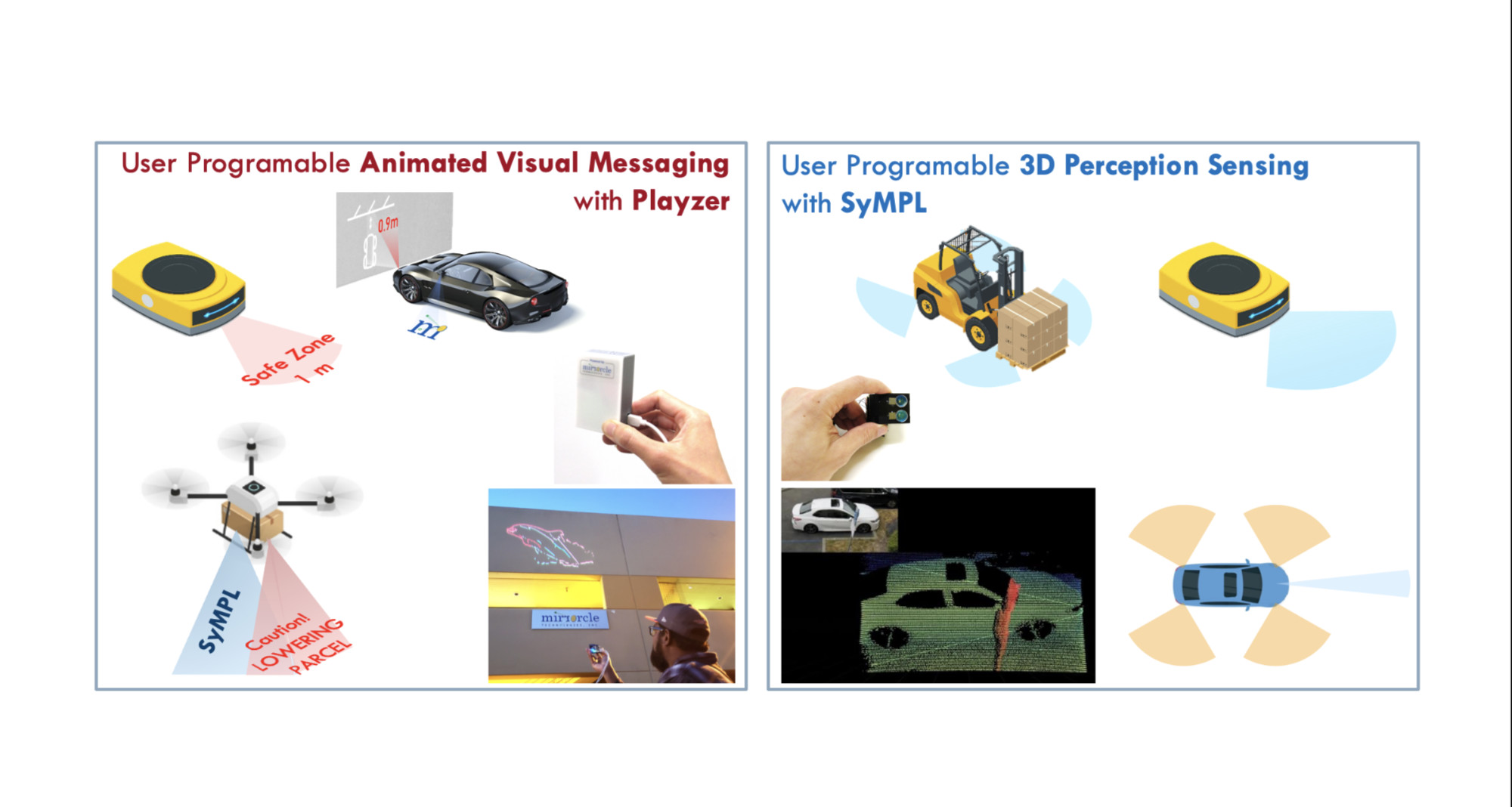

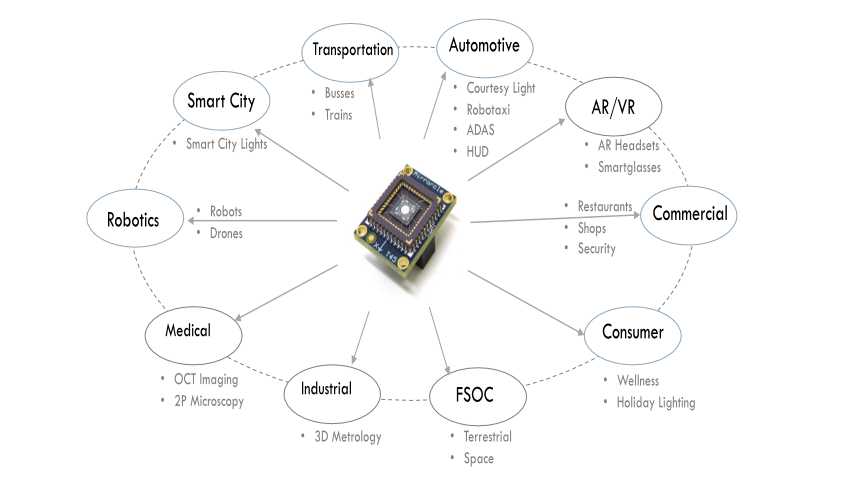

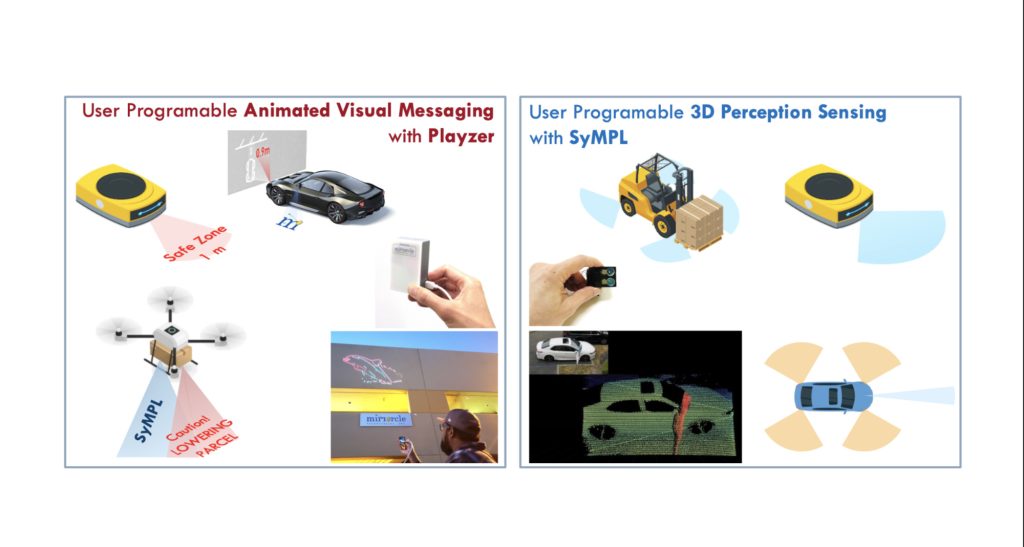

L.R: Mirrorcle Technologies is a leading supplier of MEMS Mirrors and programable light solutions. Mirrorcle has developed single and dual-axis MEMS mirrors based on proprietary gimbal-less IP. We have developed pocket size laser projector marketed as Playzer, and one of the smallest Lidars marketed as SyMPL. We offer our products as standalone devices, subsystems, or complete systems. Moreover, Mirrorcle has been developing for years proprietary software, a key differentiation feature in our solutions. For our manufacturing we rely on foundry and CM services. Our products are used in VGLP projectors for human-machine interaction including robots and drones, systems for optical communications, 3D Scanning and Metrology in industrial production, optical scanners in medical applications, and many other applications. For our manufacturing we rely on foundry and CM services.

E.E: What are the main areas of activity of the company?

L.R: The company has been developing MEMS Mirrors for more than a decade and is the leader in this field with strong IP. Whenever a solution for moving an optical or laser beam in controlled direction is needed, a MEMS Mirror becomes essential. We offer off-the-shelf products, but we tailor products to our customers’ needs. Thanks to our offerings, customers can get custom-made solutions and embed them further into more complex designs.

E.E: What’s the news about your new products?

L.R: Currently we are enhancing products by introducing hermetically packaged devices, RGB Playzer, and developing the smallest form factor Lidar in the world. In addition to hardware and software, the company has recently added development efforts in AI for the enhancement of MEMS Mirror technology platform.

E.E: What are the ranges of products?

L.R: We offer MEMS Mirrors from sub-mm to 7 mm in diameter – the most comprehensive product portfolio in the world. This level of wide-bandwidth programmability is not available from other competitors. On the Playzer side we offer mono-projectors in four different colors, R, G, B and violet. And we offer one of the smallest mid-range Lidars. We also offer a variety of development kits coupled with proprietary software.

E.E: What is the state of the market where you are currently active?

L.R: We see the market state on three levels. The first level includes market segments that are developed, like medical OCT, or 3D scanning in industrial segment. Mirrorcle is the absolute leader in these segments. The second level is made up of market segments in the early growth, like the FSOC. Here, customers are already having success with some initial wins; we are the leader in that market too. Finally, the third level is made of new market segments that are undeveloped; this is the future market; good examples are in automotive segments, XR/AR/VR, smart city, etc. Here too, we have been collaborating with strategic partners on new products to capture forthcoming growth.

E.E: What can you tell us about market trends for MEMS Mirrors applications?

L.R: MEMS Mirrors are at the cusp of explosive growth. They are becoming ubiquitous and can be found in many different applications including industrial precision manufacturing, robotics, transportation, automotive industry, smart city/smart lighting infrastructure, communications, XR/AR/VR, health care, security, and many consumer applications. MEMS Mirrors have reached maturity after a couple of decades of intensive development efforts. They are reliable and cost-effective products, well positioned for enormous growth. The MEMS Mirrors will be the next big thing in MEMS technology. We estimate that MEMS Mirrors will pass 1 billion units in annual shipment in the next ten years. One may ask: Is that realistic? Yole estimates that in 10 years the total shipment of MEMS devices should reach 50 billion units per year. One billion units of MEMS Mirrors would represent only 2% of the total number of MEMS devices, so, YES, we believe it is realistic, given the numerous applications that MEMS Mirrors are expected to enable.

E.E: What are the most innovative products marketed?

L.R: Innovation is essential to Mirrorcle success, and it is a part of our DNA. VGLP RGB Playzer is an excellent example of innovation that offers unparallel brightness and sharp images in a daylight environment. Another example of innovation would be a Lidar in the matchbox formfactor with only 1W of power consumption, and weight of less than 50 gr. Yet another example is the fusion of 3D perception sensing and projection capability. We hold a fundamental patent in that area. Everything Mirrorcle does is based on innovation. To be a successful company one must embrace innovation, listen to customers, and expand competence by investing in R&D.

E.E: What estimations do you have for 2024?

L.R: We expect inventory correction to playout and slow growth for the year driven by the overall geopolitical situation. So, it will be a good time to assess your strategy, realign your R&D efforts, and position the company for strong growth beyond 2024. The MEMS Mirror landscape is currently defined by small players. To capture the anticipated enormous market opportunities, they will need significant capital and strong strategic partners, thus we expect a consolidation process to start in this market segment.