Mitsubishi Gas Chemical is one of Japan’s leading chemical manufacturers, leading the way in developing innovative technologies that are beneficial in today’s society. The company’s motto is to offer unique products through original technology.

Interview with Peter Lavelle, Assistant Sales Manager at Mitsubishi Gas Chemical.

Easy Engineering: What are the main areas of activity of the company?

Peter Lavelle: We manufacture products in a wide range of fields from natural gas to basic chemicals that are used in day-to-day life, fine chemicals that require advanced technological capabilities and functional materials. Using proprietary technologies and processes, we engineer new materials and cutting-edge products that are improving the way we do business and protecting our most important assets.

E.E: What are the ranges of products?

P.L: MGC is a true innovator when it comes to manufacturing specialty technologies that enhance the quality, performance and value of diverse products in myriad industries. From the world’s first oxygen absorber used to protect pharmaceuticals, industrial metals and foods, a variety of cleaning agents used in the electronics field, to industrial plastics with excellent mechanical strength and heat resistance, MGC is revolutionizing how companies are doing business in a multitude of markets.

E.E: What’s the news about new products?

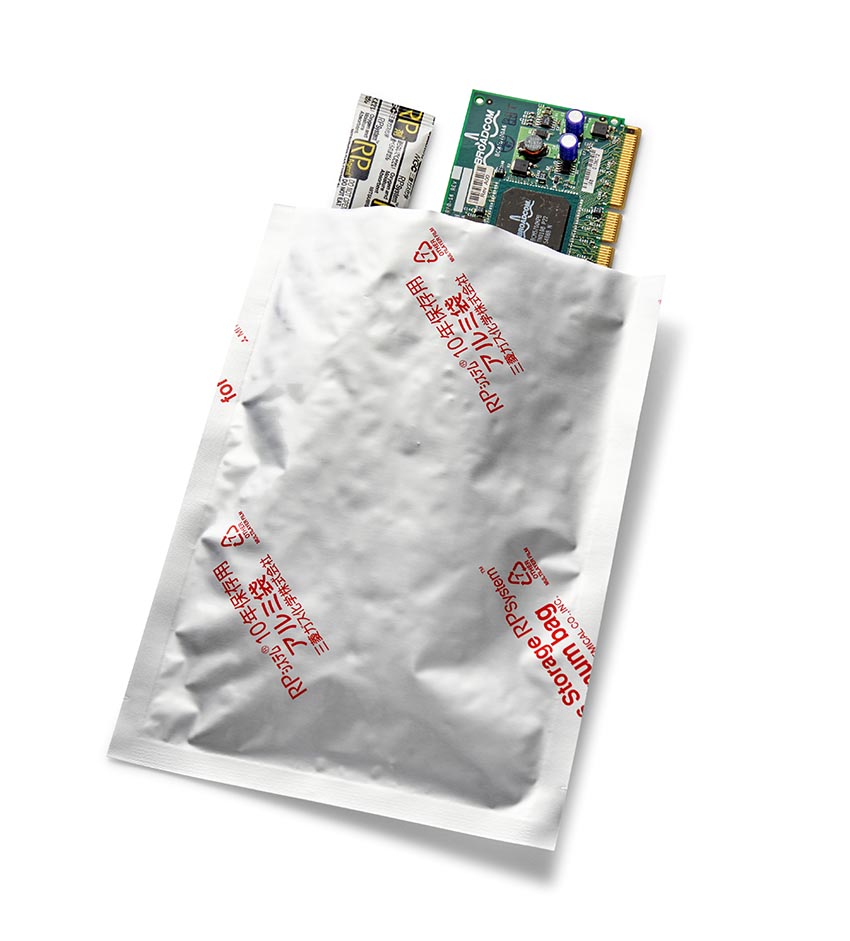

P.L: MGC recently introduced RP System, a unique packaging technology that protects and extends the shelf-life of sensitive products, to the North American market. Part of the AGELESS family of oxygen absorbers, RP System is designed to safeguard auto parts, electronics and industrial components from moisture and oxygen damage, effectively allowing them to be stored for years in pristine condition. By simply placing your product and one of our customized RP agents inside a gas barrier bag that’s been hermetically sealed, you are essentially creating an environment in which oxygen and moisture are virtually eliminated – in some cases for up to 10 years of storage.

E.E: At what stage is the market where you are currently active?

P.L: While RP System has been available in Europe and Japan for nearly two decades, MGC saw a need to bring this game-changing technology to US and Canada. At a time when supply chain issues are causing massive delays and wide-spread shortages globally, RP System provides manufacturers working with delicate parts and components – everything from circuit boards to semiconductors chips – a simple and cost-effective solution against corrosion and other forms of oxygen- and moisture-based degradation during overseas shipping and long-term storage.

E.E: What can you tell us about market trends?

P.L: As a result of the supply chain crisis, we are seeing companies across many industries, from automotive, electronics, medical device and pharmaceutical products to raw ingredients, attempting to respond to demand surges and labor challenges in various ways. With products that are transported in container ships experiencing lengthy delays, companies are being forced to make the tough decision to adjust production schedules and plan for downtime or to ship by air, an increasingly limited and price-prohibited shipping option.

This crisis is leading many companies to prioritize stability over lean manufacturing, with the supply chain situation not expected to clear up in 2022. Many companies are most likely preparing for the worst-case scenario rather than being caught by surprise as many were soon after the pandemic literally shut down the world.

In the current manufacturing climate, sustainability continues to be an important topic and a goal many companies are striving to achieve. With this year’s COP26, many nations are now engaged in effectively reaching net zero carbon emissions in the coming decades. How these goals are met rests squarely on the industry’s shoulders, and this is affecting decisions on everything from material sourcing, production scheduling, to even considering the role of the end user.

When discussing sustainability, it is important to consider the net carbon footprint, and in the end making production more efficient to accomplish these goals. Ultimately, these changes will translate to savings for companies. Under this current environment, trends are indicating the need for a more dynamic and flexible production model to meet stable and sustainable supply.

E.E: What are the most innovative products marketed?

P.L: MGC, having invented the first oxygen absorbing technology of AGELESS Oxygen Absorbers, is constantly pursuing disruptive technology. As mentioned earlier, RP System is receiving its first official launch in North America, providing protection from both oxygen and moisture and preserving the quality of everything from electronics, automotive parts and industrial components to bio-pesticides.

This is the only product in the market that provides both oxygen and moisture protection in one system, allowing manufacturers to think about their supply chain and production differently.

Due to RP System’s long shelf life, suppliers and OEM’s can operate larger production runs compared to smaller batches and be confident that they have sufficient stock in storage. Furthermore, the technology’s long-term protection also extends to the end user, who can be assured that the product’s quality or performance has not been affected during transit and that it can be used immediately upon receiving it or even years in the future.

By moving away from energy and resource-intensive lean manufacturing and changing the packaging culture, manufacturers can achieve a more sustainable operation through more efficient and flexible production, easing the burden of unpredictable parts forecasting in the future.

E.E: What estimations do you have for 2022?

P.L: All indications are that the global supply chain crisis will only get worse before it gets better so manufacturers are going to need to put a safety net in place that provides them greater production flexibility to ensure they have a steady and stable supply.

In addition, companies will need to prioritize their sustainability initiatives to meet growing consumer and governmental pressures. Therefore, it is imperative that companies learn to pivot and modify their current manufacturing methods to overcome the new challenges impacting industries everywhere.