Modula is the name of the Italian company that designs and manufactures automatic vertical warehouses suitable for any industrial sector or environment. Modula is also the name of the warehouses they make which are used to store various types of product, from small electronic components or pharmaceuticals to heavy and bulky objects like moulds or engine/car parts.

These vertical warehouses are designed to reduce occupied floor space by 90%, increase productivity, speed up picking throughput and improve warehouse efficiency by reducing risks to both people and goods. The first Modula was produced in 1987.

Easy Engineering: What are the main areas of activity of the company?

MODULA: For sure you know VLM: Vertical Lift Module.

Vertical storage solutions are perfect for making the most of the height of the buildings while saving floor space; are the ideal answer for an orderly, clean, safe and fast warehouse.

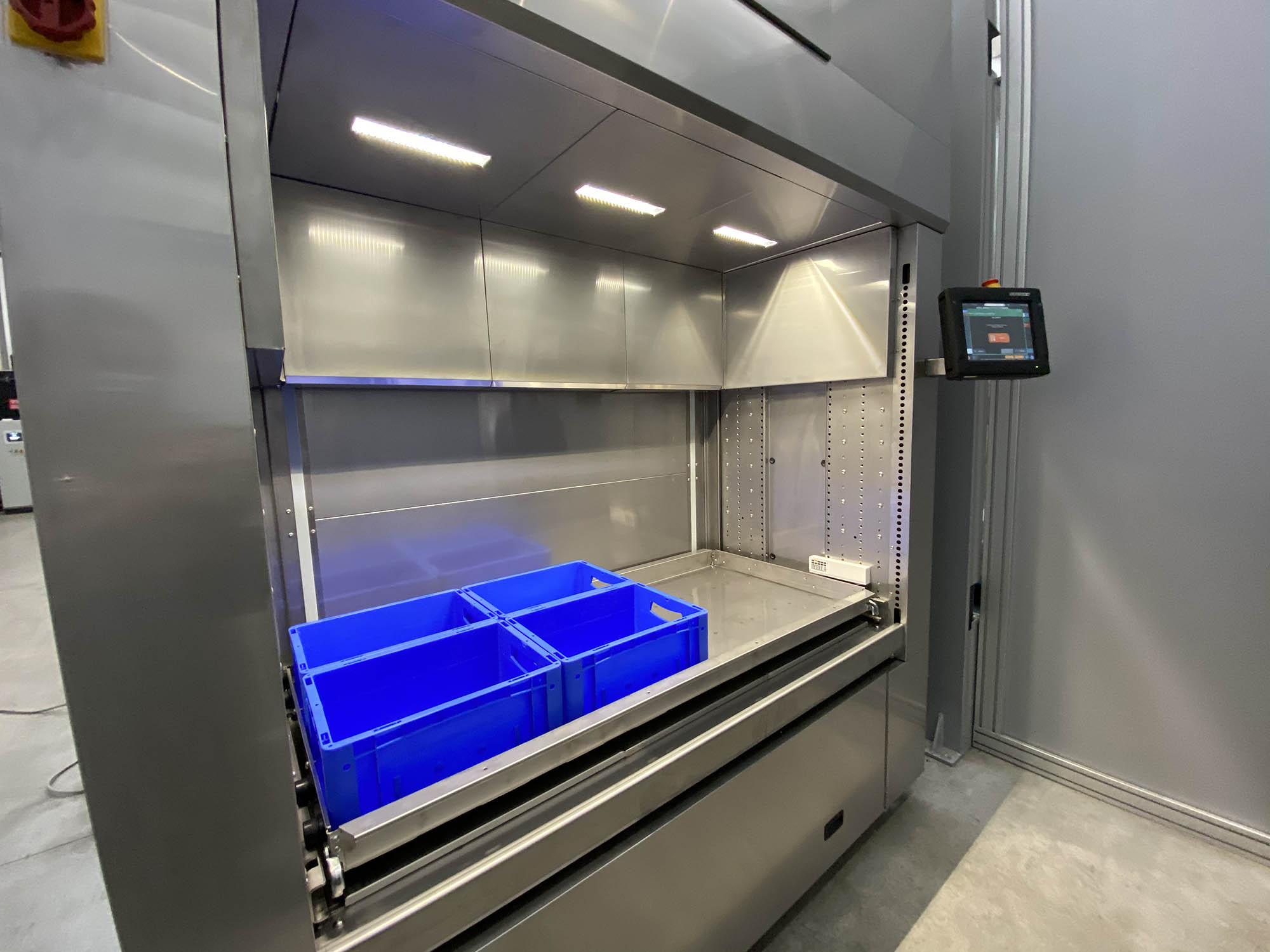

A vertical warehouse is composed of a sturdy steel structure that houses and supports the trays, a motorized central elevator to move them from the support shelves to the operator bays and one or more bays for picking up and pouring the materials.

Following the principle of goods to man, the goods are delivered to the operator in a perfectly ergonomic position.

E.E: What’s the news for 2021 about new products?

MODULA: In the last months, Modula S.p.A. introduces new designed to maintain the cold chain and operate in controlled environments.

The three solutions developed by Modula are:

- Modula Climate Control: Controlled temperature and humidity storage systems;

- Modula Clean Room: Storage systems for clean rooms;

- Modula Dry: Low humidity (dry room) storage systems.

Today, companies in all sectors need to invest in logistics, a fundamental driver which is often a critical success factor. It is well known that a warehouse is not merely a storage place but a real backbone of the supply chain, a catalyst of added value which, if well managed, can provide benefits to the entire chain, both upstream and downstream.

Those who work in sectors such as the pharmaceutical, food, chemical or electronics sector look for automated solutions that facilitate access to SKU codes while meeting the need to access a high number of items on the one hand and to make the most of the available space on the other. In addition, the regulations in these sectors are often stringent and specific equipment and structures are required for the storage of certain goods.

These were the needs that prompted Modula to develop its new storage solutions. Let’s take a look at them in detail:

Modula Climate Control

Designed for storing materials in environments subject to variations in temperature, where the accurate control of storage conditions is therefore necessary in order to prevent the interruption of the cold chain or deterioration of the stored materials. Some of the sectors in which this need is critical are the electronic, chemical, pharmaceutical, plastic and food sectors. Whether we are talking about manufacturing or distribution industries, safety is a top priority in warehouse design, and it is essential for products and/or components to be kept under strict control and constantly tracked.

Thus, Modula Lift was engineered to guarantee an efficient storage environment with controlled temperature and humidity conditions. Modula CC offers an operating temperature range from +2°C to +25°C (±1°C), with a relative humidity control >5%.

Modula Clean Room

Most semiconductor manufacturers, hospitals, and chemical, electronics and pharmaceutical companies need storage systems capable of operating inside clean rooms while ensuring that the class of the room itself is not affected and preventing contamination of the stored materials.

Whether the materials are sterile instruments for operating rooms or dust sensitive components for semiconductor manufacturing, Modula Clean Room solutions offer conditions that comply with ISO 14644 standards and meet class 7 and 8 requirements.

To keep the quantity of particles in the air as low as possible, it was necessary to work on two main aspects: limit the production of dust by the storage system during operation as well as the deposit of any dust existing in the clean room on the surface of the storage system.

Modula Dry

Just as there are materials sensitive to temperature and dust, there are also materials that suffer from the presence of humidity: thus, for the storage of these materials it is necessary to ensure that the relative humidity present in the environment is below a certain value.

The electronics, automotive and semiconductor industries are some typical examples of sectors in which these specific solutions are widespread. From a technical standpoint, solutions similar to those for temperature control are adopted when it comes to guaranteeing a relative humidity below 5%.

“These three different highly technological products expand our range and represent an efficient and cutting-edge solution in terms of storage under controlled conditions. Our goal is to respond to the demand of rapidly evolving sectors and guarantee our customers maximum flexibility thanks to scalable and modular systems,” explains Managing Director Massimiliano Gigli.

E.E: What are the ranges of products?

MODULA: Modula creates advanced automated storage and retrieval systems to transform material handling – dramatically boosting productivity and accuracy, reducing storage space requirements, and enhancing worker safety and job satisfaction.

Vertical lift modules and horizontal carousels available in a wide range of widths, heights and capacities, suitable for everything from small retail outlets to giant distribution centres, ideal for high-speed order fulfilment applications as well as any low-ceiling environment.

E.E: At what stage is the market where you are currently active?

MODULA: Today, Modula has more than 15,000 clients around the world and a production capacity of 3,500 machines per year from its 3 production facilities in Italy (Salvaterra di Casalgrande, Reggio Emilia), USA (Lewiston, Maine and Franklin, Ohio) and China (Suzhou).

Besides these facilities, we have 9 subsidiaries in Europe, America, Asia and Africa and a vast network of 50 authorised distributors. This ensures we have a presence where our clients are, allowing us to service all our main markets and respond quickly and locally to all our client’s needs.

E.E: What can you tell us about market trends?

MODULA: As for now, the consumer’s behaviour and needs change every day under the economic alteration. So, the supply chains depend not only on on-demand and delivery. Shippers must go on with the consumer’s needs and satisfy them.

The supply chain follows the market trend.

We can consider 2 kinds of customers in the contemporary market: digital and global.

It means each potential customer has the access to each product of every company under the hand. So, the competition between the manufacturers is very strong and companies have to innovate the products and make a faster supply chain.

Everything is very fast: trends appear and disappear quickly. It means all industry need flexibility and adaptability so they have two ways to work under the hesitation of the supply chains: agile supply chain and lean supply chain.

Logistics has been considered for a long time a cost centre to be optimized, making warehouse logistics operations efficient and effective has become a milestone to success for many companies.

For company’s competitive advantage, a strategic asset means:

- Important Savings;

- Proper management and allocation of spaces, vehicles and operators;

- reduction of lead times;

- increasing in safety and sustainability.

E.E: What are the most innovative products marketed?

MODULA: We are working on VLM interconnection and 4.o Industry that is not automation but interconnection. The human operator, connected to the system via smartphone, field terminals, tablets and RTLS systems, can possibly be ‘guided ‘, helped by the system.

It means solutions like Modula Cloud and WMS

Modula Cloud is the portal that Modula offers its clients to allow them to view and report on all information relating to warehouse activities including:

- system registry data;

- warehouse status;

- consumption;

- occupation (weight – volume – surfaces);

- tasks;

- maintenance;

- opening assistance ticket;

- trays;

- machine log and much more.

The platform lets you connect the Modula vertical warehouses managed by Modula WMS software to the Modula Cloud portal. Modula WMS collects and processes the information and activities from the warehouses, then transfers them to the Modula Cloud, which allows them to be viewed on an internet site that is accessed via personal authentication.

MODULA CLOUD ADVANTAGES ARE:

SAFETY

Developed entirely with Microsoft technology, it is hosted on the Azure platform which guarantees the highest levels of security. It uses the latest encryption systems for authentication and data exchange between WMS and Cloud.

SUPERVISION AND CONTROL

It will be possible to know if the VLMs are in operation or in alarm, how saturated they are in terms of volume, weight and surface area, how many cycles have been made and how many orders have been processed, the alarm history, energy consumption and other relevant data.

PREVENTIVE AND INTELLIGENT MAINTENANCE

Real-time monitoring, of any malfunctions, allows immediate interventions, and statistical analysis of the data facilitates the generation of predictive maintenance algorithms. No more unexpected shutdowns, fewer unnecessary and expensive activities, more process control.

DIRECT LINE WITH CUSTOMER CARE

With Modula Cloud, accessing the VLM remotely makes it easy to understand problems and solve them quickly. Statistically 80% of downtime can be solved in this way without on-site interventions.

E.E: What estimations do you have for 2021?

MODULA: In our industry 2021 started very well, after all the uncertainties brought by the pandemic last year; the market is slowly gaining traction and companies are heavily investing in logistics and automation.

The dynamics imposed by the pandemic and the powerful advance of E-Commerce, which in 2020 grew by 31% in terms of product purchases (source: B2C eCommerce Observatory, PoliMI), push many companies to revise their logistic models and optimize all warehouse and production processes.

Food & beverage, E-commerce, E-grocery and pharma are our focus for 2021 because of their big investments.

Industrial manufacturing that slowed down in 2020, now is restarting to consider significant investments. Most companies strongly believe that logistic automation can improve their business, agility and profitability; in these cases, Modula vertical solutions fit very well and with their fast Return of Investment are a “no brainer” choice to switch from a traditional to an automated warehouse.