Molecor is a leading Spanish company that develops Molecular Orientation Technology applied to pressurized water pipes. It specializes in the manufacture of Oriented PVC pipes and fittings for pressurized water conveyance.

Founded in 2006, Molecor began it business focusing on two main lines: the development of cutting-edge Molecular Orientation technology applied to PVC and the manufacture of highly effective solutions for pressurized water transport.

Molecor currently has production plants in Spain, Paraguay and South Africa, technology installed on 5 continents with more than 20,000 kilometers of TOM® pipe installed around the world and is currently experiencing rapid expansion of its PVC-O ecoFITTOM® fittings.

Easy Engineering: What are the main areas of activity of the company?

MOLECOR: Molecor has two headquarters in the province of Madrid, Spain. In Getafe there are facilities dedicated to R&D, a center in which new, increasingly efficient systems are developed for the manufacture of PVC-O products for the transport of pressurized water. The development of technology to manufacture PVC-O pipes up to DN1200 mm is one of the latest projects the company is working in together with the development of technology for the manufacture of PVC-O fittings.

The production center with 9 production lines for TOM® PVC-O pipes is located in Loeches. Installations in which pipes of all available diameters are produced, from DN90 to DN1000 mm in pressures from 12.5 to 25 bar, and ecoFITTOM® PVC-O fittings from DN110 to DN400 in PN16 bar. These products are manufactured with the technology developed exclusively by the company and are exported to the five continents. Thousands of kilometers of TOM® PVC-O pipes are already installed around the world in supply networks, irrigation, reuse, fire networks, etc.

E.E: What’s the news for 2021 about new products?

MOLECOR: This year we will again be the first to reach a new record in Oriented PVC pipes, producing a diameter of 1200 mm. And we have a very active R&D area with CPVC-O projects, the most suitable product for earthquakes, self-locking solutions, etc.

We are continuously improving all of our production processes through advanced data analysis in our three factories.

SUSTAINABILITY is one of the keys to our medium / long-term strategy and for this reason we are implementing programs such as Operation Clean Sweep, a global and voluntary initiative of the plastics industry to reduce the loss of primary microplastics, in any of their forms by environment. Working on our own EPD (Environmental Product Declaration) of our pipes and fittings and also setting up a photovoltaic installation in our Loeches factory in PPA (Power Purchase Agreement) format, a long-term 100% sustainable energy purchase agreement that does not require an initial investment.

In the commercial part, apart from continuing with the growth in our reference factory in Loeches with 2 new lines and the growth of our plant in South Africa and Paraguay with one more production line in each of them, we have two other implementation projects very advanced that we hope to launch before the end of the year: one in Eastern Europe and the other in Latin America.

E.E: What are the ranges of products?

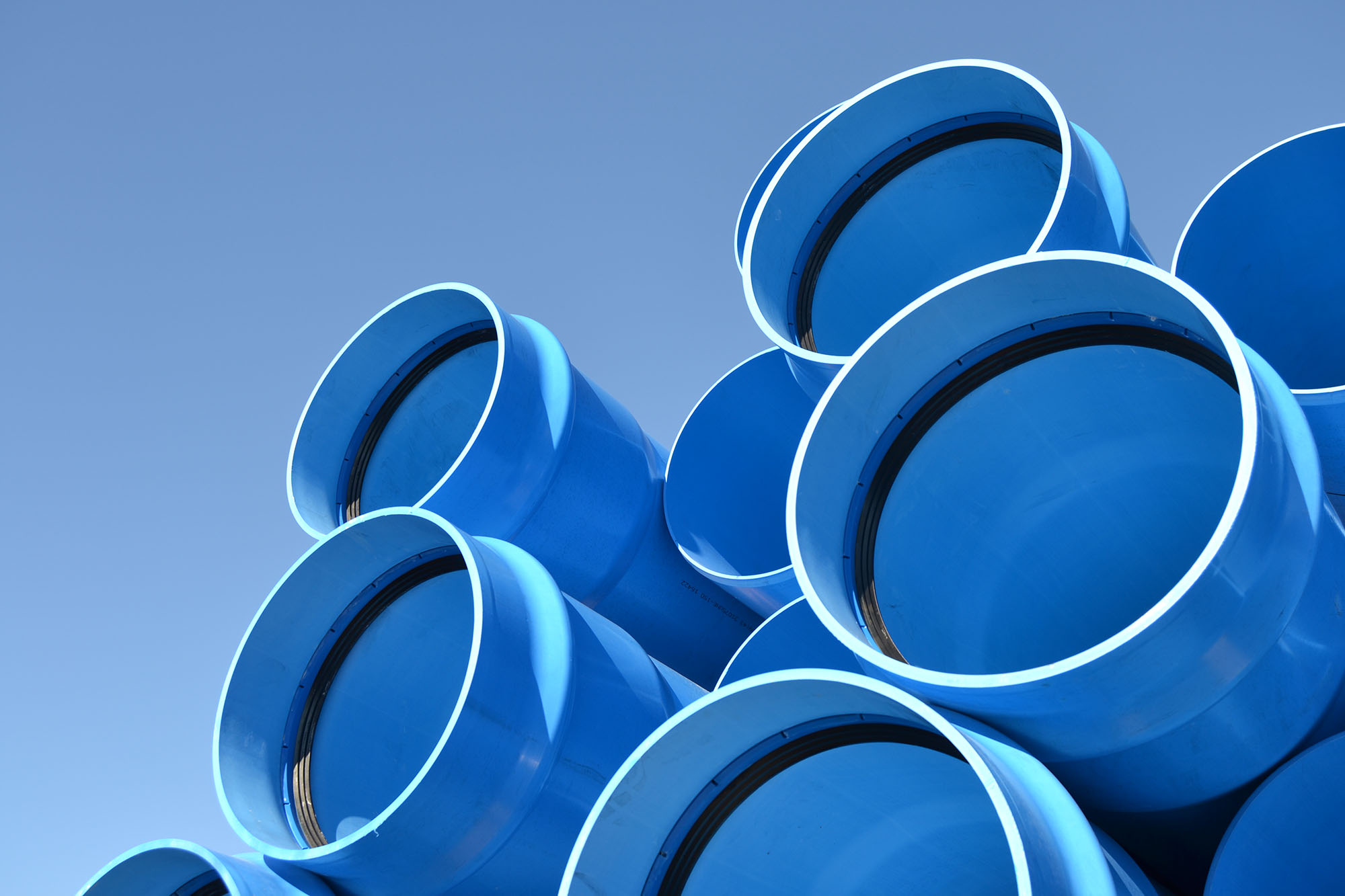

MOLECOR: The TOM® PVC-O pipe has a wide range able to cover all the needs of medium and high pressures. TOM® is manufactured from DN90 to DM1200 mm and pressures (PN) 12.5, 16, 20 and 25 bars.

It is supplied in total length (including socket length) of 5,95 m, but other lengths for special projects may be considered.

TOM® PVC-O pipes are manufactured in accordance with UNE-EN 17176:2019 standard, based on European Standard EN 17176 and also according to the International Standard ISO 16422:2014.

TOM® is only manufactured in the highest Molecular Orientation class (PVC-O Class 500) since with its highest orientation degree it guarantees better mechanical behavior.

Currently, ecoFITTOM® are manufactured in DN110, DN160, DN200, DN250, DN315 and DN400 in PN16 bar. The available range of products is being progressively widened until covering all the market demands.

E.E: At what stage is the market where you are currently active?

MOLECOR: Molecor is a global company and great part of its success, besides its state of the art technology, is the fact that it is present worldwide. Diversification makes that, first of all, Molecor market is each year enlarged and, second of all, that Molecor is more flexible to face unforseen situations, as we all know have experienced this past year with COVID-19 pandemic.

We are very much active in our „local” market which is Spain, Portugal, France, UK, Italy and East Europe. Also, South America and South East Asia. Our local market has experienced a great growth, over 20%, in 2020 and it is continuing that trend. Water project are considered essential and therefore they do not stop, neither the funding nor the execution. In South East Asia COVID-19 pandemic has delayed many projects, but we are optimistic for the second half of 2021 and 2022 and it will lead shortly to a local factory in the territory. In South America, our market share has also continued to grow during our last year and we have great expectations for this 2021.

E.E: What can you tell us about market trends?

MOLECOR: Currently, the greatest challenge that plastic pipe industry is facing is raw material scarcity, and therefore its scalation of prices. During the last year the PVC resin, main component of PVC and PVC-O pipes, has almost doubled its price leading to a great crisis in the sector, having as a result in many cases PVC transformers with their factories lock down, not due to COVID-19 (that also has challenged manufacturing sites to keep their workers safe), but due to lack of resin. And when there is resin, it is impossible to maintain prior prices with current costs. This is a crisis, that eventually will calm down, but as per today we are not certain if the peak has already been reached. So far, the trend has been up.

E.E: What are the most innovative products marketed?

MOLECOR: Molecor is characterized for being an innovative company in the pressure pipeline sector, as demonstrated by its trajectory since it has been the first company in the world to manufacture products such as DN500 mm, DN800 mm pipes and recently, the DN1000 mm Oriented PVC pipe.

It is also the only company that manufactures fittings in this material, Oriented PVC, making a complete solution in this material available to the market.

In addition, Molecor also markets its exclusive technology for the manufacture of PVC-O pipes, a highly efficient technology capable of manufacturing the widest range of diameters in this material.

E.E: What estimations do you have for 2021?

MOLECOR: 2021 is being a challenging year because of COVID restrictions from a commercial and productive point of view. But also, infrastructure projects have continued to be implemented in both our local and abroad market. Therefore, we are very optimistic with our budget and our growth estimation of 20% compared with 2020 (which was a good year also), seems very much feasible at this point of the year.

Raw material crisis should reach its peak in following weeks and before the end of the year it should come down. Not to prior prices, but at least not to twice resin price last year, giving some air to pipe manufacturers and final customers.