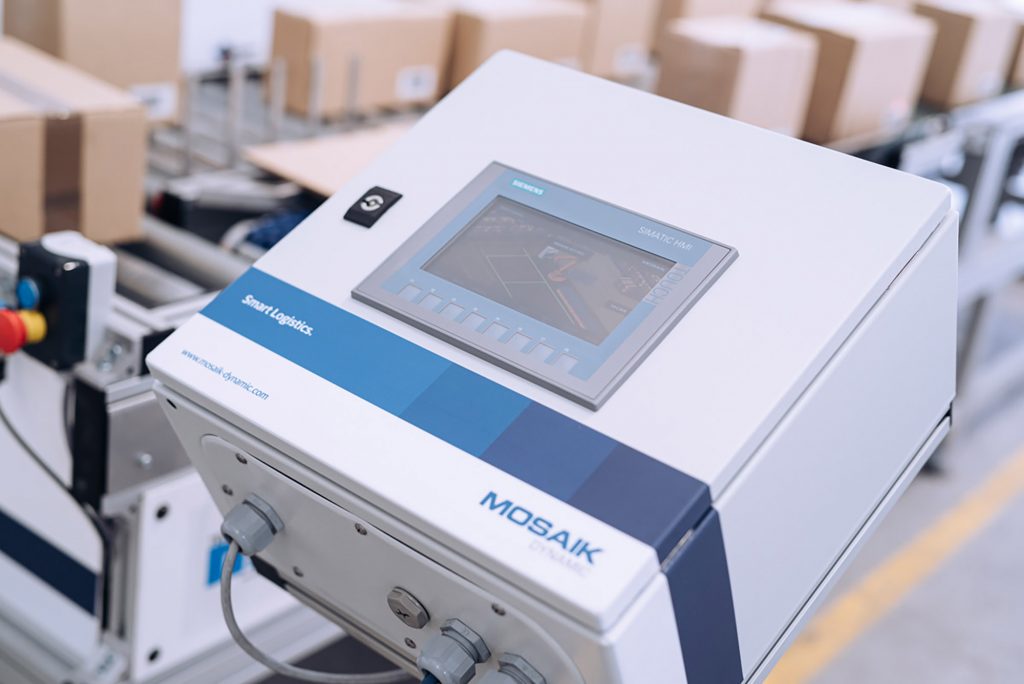

Mosaik Dynamic is a technological innovation company that was born to respond to the needs of industry and logistics 4.0. The main objective is to create added value to the logistics processes of companies through artificial intelligence with our products for the automation of the end of the line.

Interview with Andrea Berni Artal, Marketing & Business Development Manager at Mosaik Dynamic.

Easy Engineering: What are the main areas of activity of the company?

Andrea Berni Artal: Mosaik Dynamic’s main area of activity is the development of both classic and mixed palletizing software with innovative and unique technology on the market registered with the World Intellectual Property Organization and protected by intellectual property protection laws.

E.E: What’s the news about new products?

A.B.A: Our latest release is the MOSAIK RT mixed palletizing system.

This technology allows the robot to autonomously palletize boxes of different sizes on the same pallet.

The launch of the improved version of our classic palletizing system, MOSAIK FX, is also planned and it will be released very soon, with new features and applications.

E.E: What are the ranges of products?

A.B.A: Our group of products are technologies oriented towards the automation of palletizing. Based on the needs of the client and the installation, we offer 3 types of software:

MOSAIK FX: The classic but ultra-flexible palletizing technology. It is indicated for robotic installations that simultaneously palletize different models of boxes that arrive from different lines. The controller globally manages a multipalet palletizing cell, providing the robot with total flexibility and minimizing downtime.

MOSAIK RT: The most innovative product: the mixed palletizing technology developed by MOSAIK DYNAMIC that allows the automation of the end of the line of a logistics installation. Combine boxes of different sizes on the same pallet creating the mosaic in real time through artificial intelligence. In addition, it is compatible with the main brands of robots on the market.

MOSAIK SQ: Uses artificial intelligence in the cloud to analyze the boxes, order them and create the optimal mosaic. It indicates to the warehouse the box output sequence and automatically palletizes the orders. This technology is in development and will be available soon.

E.E: At what stage is the market where you are currently active?

A.B.A: Both the logistics sector and the automation and robotics sector, which would be our main lines of action, are in full growth.

The market is in a good moment and every time the client is more aware of the benefits of automating logistics processes.

In our specific case, we identified in the market the need to automate mixed palletizing, which is traditionally done by hand, with a system that can be easily integrated and adapted to the production line, that does not require a large investment and that is also capable of work in real time. As far as we know, today we are the only company that offers this type of technology with these very specific characteristics since, in the rest of the solutions that exist, it is necessary for the system to know in advance the total content of the order to be palletized or the order in which the boxes arrive at the robot; in our case it is not like that: the system works in real time.

E.E: What can you tell us about market trends?

A.B.A: Both the logistics and robotics sectors are experiencing significant growth and there are two main trends that directly affect us in each of them:

On the one hand, in the logistics sector, the automation of processes is gaining ground, which represents a great opportunity for companies like us. The savings in costs and time involved in automating a warehouse, the end of the line, palletizing… is very important for a sector that generally works with very tight time frames.

Regarding the robotics sector, for our part we would highlight Edge Computing and the rise of artificial intelligence.

E.E: What are the most innovative products marketed?

A.B.A: Without a doubt, our most innovative product is MOSAIK RT.

Currently, mixed palletizing is done manually, but this entails a series of problems that we can avoid by automating it: such as work-related accidents, sending a package to the wrong destination, or damage to the merchandise.

Therefore, the benefits provided by this mixed palletizing technology and the rapid return on investment make it a profitable and efficient system for companies and their processes.

The most remarkable novelty of MOSAIK RT is that the system is able to choose the optimal placement for each of the boxes that advance towards the robot and change the plan as new boxes are added if necessary. The system creates the mosaic in real time, that is, without prior order planning or sequencing.

E.E: What estimations do you have for 2022?

A.B.A: Our goal for 2022 is to continue growing as a company and developing solutions for the automation of logistics processes and industry.

Much remains to be done to improve the profitability and efficiency of companies’ production and logistics processes, although the sector is on a very good path and our goal is to position ourselves as one of the leading companies in it.