Moso3D is a new developer and manufacturer of 3D printers and additive manufacturing equipment. The company is focused on FFF technology, but they develop custom tools for pellet extrusion, silicone and paste, metal extrusion, laser engraving, etc.

As specialists in 3D printing, the Moso3D team has developed a machine with the features they always wanted in a printer. The Moso MT printer has features such as self-calibration of the bed height, self-calibration of the offset between extruders, heated chamber, Hepa filters, magnetic hot bed, heated material bay. In short, everything you need to get the best printing experience possible.

Interview with Víctor Abad, Marketing Manager at Moso3D.

Easy Engineering: What are the principal areas of activity of the company?

Víctor Abad: Moso3D is focused on Additive manufacturing development in professional sectors with main customers from industrial maintenance, technological & engineering centers for material testing, medical sector and professional users in 3D printing departments.

Moso3D took the idea that has already been implemented and working in the world of CNC machining (automatic interchange of different tools) and developed a 3D printer capable of housing multiple extruders.

That is why Moso3D is not only focused on the printer itself, but on the development of new tools. Adapting the technologies that are appearing on the market to this tool changer system.

E.E: What’s the news about new products?

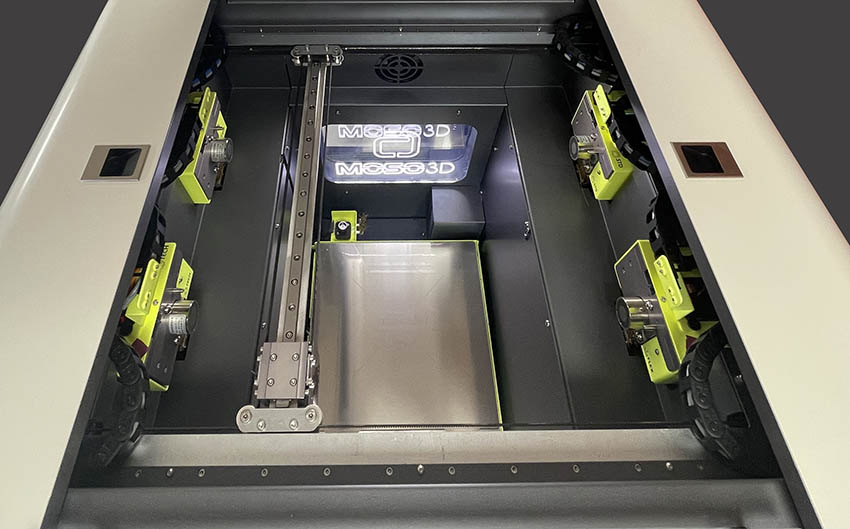

V.A: Moso MT is an automatic tool exchange system that allows custom extruder combinations for each application.

The versatility of a multi-tool system like this allows for a multitude of applications and advantages over fixed multi-extruder systems.

From the simultaneous use of different nozzle diameters to the ability to use filament of different diameters (1.75 or 2.85 mm) in the same print to the possibility of having spare extruders of distinctive characteristics ready to use. Thanks to the interchangeable system of extruders, it is easy to mix up to 4 materials without contamination between them, thanks to the fact that each material has its own extruder.

E.E: What are the ranges of products?

V.A: The 3D printers

Our main product is the MOSO MT 3D printer and the MOSO MT ECO version.

The MOSO MT printer uses a custom Core XY system which, together with a strong chassis, supplies a robust platform for the motion system, delivering high-quality print speeds and accuracy.

The materials that it is capable of printing, under the open-source material philosophy, is a wide variety of thermoplastics, and this list will be increased with the development of new heads/tools in the future.

Being able to choose the diameter of the nozzle from the slicer, and not needing any manual action to change the diameter, is one of the advantages. Being able to use filament of different diameters (1.75 or 2.85 mm) in the same print, mixing up to 4 materials without contamination between them thanks to the fact that each material has its own extruder or just having spare extruders ready to print if a jam occurs are just some of the improvements.

4 tools / extruders FFF technology

- Print volume 300 x 300 x 300 mm

- External size 800 x 600 x 800 mm

- Bed temperature 150ºC

- Chamber temperature 70ºC

- Auto-leveling & Auto-offset

- Material Moisture Control / Heated material bay

- Hepa filter

- Automatic sliding door

- Intuitive interface

The Tool Heads

Moso3D introduced 3 tools, each custom designed to reliably print a wide range of materials. All of them with precision machined components that allow exact control of printing and positioning parameters, and include an accelerometer to auto-calibrate prints, dropping defects and increasing quality.

“Up to 4 simultaneous tools. Combinable according to your needs”

STANDARD TOOL: An all-terrain extruder for most applications. Direct extrusion, brass nozzle, temperature up to 280ºC and filament diameter of 1.75 mm.

FLEX TOOL: Tool specially designed for flexible filaments. Direct extrusion, precise control of the pressure on the filament, brass nozzle, temperature up to 280ºC, filament diameter of 2.85 mm. Capable of printing even the most flexible filaments with hardness of 60 Shore A

TECH TOOL: A tool designed to print technical materials reinforced with abrasive fibers at elevated temperature. direct extrusion, hardened steel nozzle, temperature up to 350 ºC, filament diameter 1.75 mm.

All the tools are built with high-quality machined components, which, together with the positioning system and accelerometer, guarantee precise and safe fixation. We are working on implementing new tools such as those for bioprinting, pellet extruder, paste extrusion, continuous fiber, laser marker, etc.

The Packs

To make starting to use the printer a simple experience, we have prepared packs with combinations of material, extruder and printing surface for a series of specific applications such as a pack for printing polypropylene, another for soluble supports that includes a cleaning station, another pack for flexible filaments, etc.

Each pack includes all you need to start printing, including custom printing profiles for our 3D printers, 2 filament spools, custom printing bed and detailed instructions on how to start printing. Using the provided extruders ONLY for those materials will keep your workflow flawless and with no other material contamination.

At this time Moso3d has 6 different packs that you can consult on its website in detail.

E.E: At what stage is the market where you are currently active?

V.A: At this moment Moso3D is only available at Spanish market. In 2023 Moso3D plans to jump into the European Market and present new tools for the tool changing system.

The Spanish market is young and still suffers from a lack of training and education in companies, although the speed of implementation of additive manufacturing follows in the footsteps of the rest of Europe, where it has not stopped growing in recent years.

Large companies have already begun the path of digitalization, now it is the turn of small and medium-sized companies that are beginning to see investment in 3D printing as a strategic advantage when it comes to improving their production processes and having versatile tools that fix problems fast.

E.E: What can you tell us about market trends?

V.A: In the sectors where Moso3D operates, especially the industrial and professional sectors, the main trends are the use of increasingly technical materials, such as metal, reinforced fibers, highly flexible filaments…

That is why Moso3D designed a machine capable of adapting to changing trends and the relatively rapid evolution of technology.

Most of the customers interested in this printer are professionals with special printing needs (such as printing very flexible materials, mixing materials or looking for a solution to be able to print polypropylene without problems), but mainly, customers who want their machines not to be outdated quickly.

E.E: What are the most innovative products marketed?

V.A: A 3Dprinter made of bamboo.

Moso MT ECO is not just a pretty design. With a reduction in consumption compared to the MT model, and thanks to its bamboo enclosure, we reduce the carbon footprint, energy consumption and increase recyclability.

Bamboo is called “green” due to the rapid growth of the plant. Using laminated bamboo doesn’t require cutting down a tree, plus it’s fairly temperature and humidity stable, and 100% recyclable.

This Moso MT ECO printer fits in design studios and places where sustainability and ecology are considered with special interest.

Ecodesign, circular economy and sustainability are present in every Moso 3D product. Thanks to our collaboration with the Treedom.org organization, Moso3D finances small agroforestry projects in different countries around the world by planting trees to offset the carbon footprint.

E.E: What estimations do you have for the rest of 2022?

V.A: Moso 3D will attend the FORMNEXT 2022 international fair with a double goal: to make itself known to the European professional 3D printing market and to look for partners and distributors for its equipment outside of Spain.

You can visit Moso3D at the Frankfurt fair, from November 15 to 18 in hall 12.1 – booth G118.