How do you feed a growing population without overwhelming the planet? That is the key question for N2 Applied, a Norwegian technology company that aims to improve global food production.

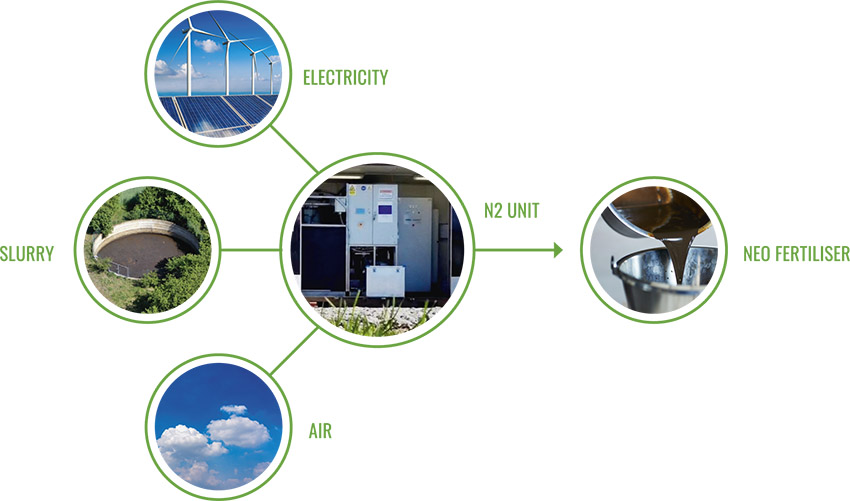

The company has developed a small machine that can upgrade organic waste, such as livestock slurry, into a high-quality fertilizer, using only air and electricity. They use plasma technology to turn air into a reactive nitrogen oxides gas which then is absorbed into a liquid substrate such as livestock slurry. This process reduces emissions of methane and ammonia from manure management, as well as provides a sustainable substitution for fossil-based chemical fertilizer.

Interview with Kåre Gunnar Fløystad, Communication Manager at N2 Applied.

Easy Engineering: What are the main areas of activity of the company?

Kåre Gunnar Fløystad: N2 Applied is a technology company that is focused on innovations related to nitrogen production. Main areas currently are the commercialization of manure processing technology, with connections to agronomic field work and further technology development. The effects on emissions and crop growth have been tested in a wide trial program, showing an average yield improvement of 40% (2020 season) compared to raw manure, and the emissions of ammonia and methane are stopped in storage and manure application.

E.E: What’s the news about new products?

K.G.F: A major milestone for us has been to demonstrate that the technology works at full-scale on regular farms, but also to get further substantiation on the environmental effects. We have now shown the potential of emission reductions with well-known independent research partners in the Nordics and the UK. The emissions of methane and ammonia are reduced and the nitrogen use efficiency of the livestock slurry as a fertilizer is significantly improved by turning it into Nitrogen Enriched Organic fertilizer (NEO). This provides further confirmation of trial results from previous years.

In 2021 the company went through a piloting phase involving 8 different farms and biogas plants in the Nordics, UK and the Netherlands. The piloting has proven the technology and lead to improvements which are now implemented in the newest generation of the N2 Unit, ready for market launch in 2022.

E.E: What are the ranges of products?

K.G.F: Our product is the N2 Unit. A containerized set of machinery that is placed on a farm to upgrade liquid manure into a sustainable, high-quality fertilizer. The machine increases the fertilizer value and reduces emissions, – using only air and electricity. By doing this, we can take fossil based chemical fertilizer out of food production and make farming more circular.

E.E: At what stage is the market where you are currently active?

K.G.F: The need for new environmental solutions in food production is clear for everyone. Consumers and policy makers demand change and the agrifood industry is looking for new ways of sustainable food production. What is missing are holistic solutions that both improve production and additionally reduce emissions. We are confident that we have developed a product that both handles the need for nitrogen to make plants grow, the importance of reduction in air pollution caused by ammonia emissions and the global call for less greenhouse gas emissions by stopping methane emissions from the manure.

E.E: What can you tell us about market trends?

K.G.F: It is impossible to look beyond the recent events in Ukraine and the uncertainties related to food security. It influences both food production, cost of fertilizers and energy, and comes in a time where the agricultural sector has been the rising production costs. It is best exemplified with the dramatic increase in fertilizer prices over the last year, causing farmers to consider reducing the use of fertilizer, and thereby the food production. Simply because the increasing production cost is taking away the possibilities to make a decent income on the products. Now food security will be increasingly important, and it might also provide a call for more independency from centralized fertilizer production.

On the longer term, we experience an increased focus for more sustainable food production. Consumers and policy makers demand change and the agrifood industry is looking for new ways of sustainable food production. The discussions from COP26 in Glasgow and the Methane pledge which were signed are calling for reduction of emissions, also from the agricultural sector. Both the UK, EU and other countries are reshaping their agricultural policy and seek to include a broader focus on the environmental side of food production.

We also see the agri-food industry taking more responsibility for the development towards more sustainable food production. Numerous companies have now pledged their ambitions towards net-zero and are looking for ways to help their producers to do the same. Consumer behavior is changing and demanding more sustainably produced food. This might lead to the agri-food industry act faster than national authorities.

E.E: What estimations do you have for 2022?

K.G.F: Through 2022 we expect to increase sales in our core markets in the Nordics and the UK. We also expect to announce the entrance into a large market very soon. By now, our order book looks good and we are seeking to upgrade our production capacity to cope with the increased demand. We are entering partnerships with both agrifood industry and agri-equipment companies.