Narran was founded in 2013 for the purpose of development and production of our own laser systems, automation, construction of single-purpose machines. Narran is a direct Czech manufacturer of laser cleaning systems. Depending on the needs of the application, the company can design and integrate the laser into production lines, build a robotic workplace or supply a portable mobile laser for a wide range of applications.

The company has experience with all types of laser applications and the possibilities of using lasers, from surface cleaning, through the engraving of materials to laser welding.

Interview with Antonín Malecký, CMO, Narran s.r.o.

Easy Engineering: What are the main areas of activity of the company?

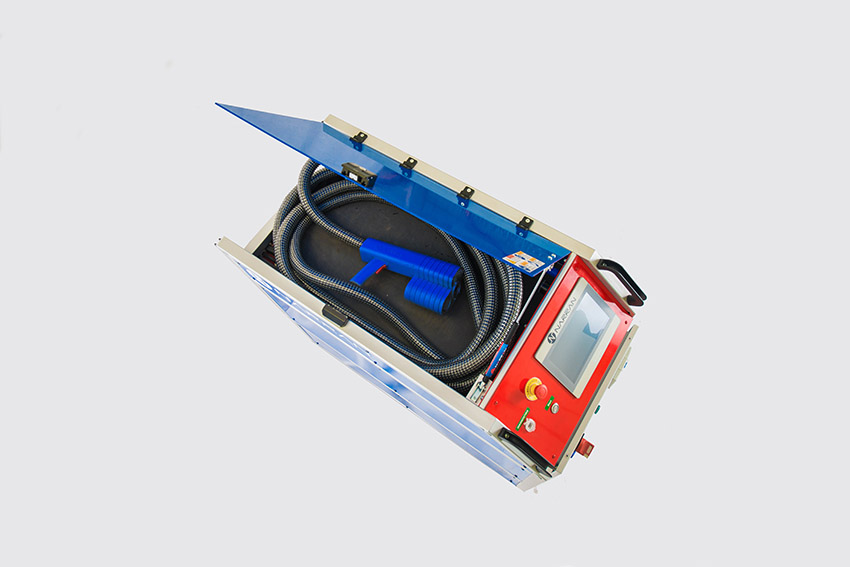

Antonín Malecký: The main product of our company is Narran ROD pulsed fiber cleaning laser. ROD Laser is a new generation mobile industrial cleaning machine, developed and built by Narran in the Czech Republic. It is equipped with a special fiber resonator, which allows cleaning without damaging the surface. ROD Laser is suitable for cleaning a wide range of materials, typically metals (cleaning rust, grease, paint, etc.), but also masonry.

We have sold cleaning lasers to more than 100 customers in more than 25 countries in the world, including USA, Australia, Indonesia, Malaysia and many others.

The main areas our lasers operate in are:

- Cleaning of industrial molds;

- baking sheets, injection molds for plastics and rubbers, printing cylinders, coated tools;

- Paint removal – paint stripping;

- Automotive industry, aerospace industry, plastic and composite materials, preparation before the next process, renovation;

- Restoration and conservation;

- Stone facades and buildings, sculptures, graffiti, revitalization of sandstone surfaces;

- Surface preparation;

- For painting, gluing, soldering and welding;

- Special cleaning laser applications;

- Surface preparation, TBC coating removal, glass/metal coating removal.

E.E: What’s the news about new products?

A.M: The most current product is world’s currently most powerful handheld cleaning laser with power of 2000W and pulse peak power of 1,3mW. The applications of this laser are especially in automotive, energetic, aviation, nuclear decontamination or space industries. The laser is available both in mobile unit with handheld process cleaning head as well as integrated into high-tech production lines for different purposes such as surface preparation or changing properties of laser ablated surface, it all ultimately depends on customers desired application. We are fully capable of adjusting lasers to best deliver the desired outcome for our customers.

E.E: What are the ranges of products?

A.M: We develop and manufacture lasers with powers between 50W and 100W that are mostly used in small range applications such as archeology and museum restoration or removing of light rust. Bigger range is 200W and 300W for use in car restoration, graffiti removal, industrial moulds cleaning, tire moulds cleaning, decontamination, cleaning of sandstone or other light types of stone and finally 500W and 1000W that are mostly being used in large scale operations, such as injection mould cleaning, heavy rust removal, automotive and aviation manufacturing applications.

E.E: At what stage is the market where you are currently active?

A.M: The laser cleaning market is currently relatively early in it’s existence, yet it is very fast growing, just waiting to be more common and known to the general public. The market is by many sources projected to grow exponentially in the few following years as the laser cleaning technology is getting more common and new applications emerge almost on daily basis. As with all technology, lasers are also getting cheaper than they were a few years ago as we manage to improve the manufacturing and development process.

E.E: What can you tell us about market trends?

A.M: The laser cleaning market is currently chipping away mostly dry ice blasting and chemical cleaning applications where laser proves to be much more efficient, ecologically friendlier and cheaper. Many manufacturers switched from conventional cleaning methods to the use of lasers to increase production speed by speeding up the cleaning processes therefore increase profits.

E.E: What estimations do you have for the rest of 2022?

A.M: Our estimations remain very positive as lasers prove to be a smart choice in most of the production areas we supply. Behavior of the market currently proves that especially laser cleaning area is just at the beginning of huge growth and we firmly hope that in a decade it will be extremely common for lasers to help with many processes, some of we might not even imagine now.