Naveena Exports Ltd. is a third-generation family-owned business, a growing conglomerate dedicated to progress and sustainability for over three decades. Naveena started as a knit wear and gradually emerged in denim industry with the production capacity of 36 million meters per annum. The group now has grown to include different sectors of energy, construction and steel.

Naveena Denim NDL is a denim manufacturing subdivision established in 2006 with production facilities in Lahore Pakistan. NDL specializes in manufacturing world-class denim fabric and has offices in Europe, US, and Bangladesh exporting denim fabric over the globe.

Interview with Rashid Iqbal, Executive Director at Naveena Denim NDL.

Easy Engineering: What are the main areas of activity of the company?

Rashid Iqbal: NDL is a denim fabric manufacturing unit producing fabrics from basic to high end fashion denims with innovation, collaboration and social responsibility.

E.E: What’s the news about new products?

R.I: With the denim industry undergoing transformation, mills, and brands are moving away from conventional products with innovation, collaborations, and social responsibility!

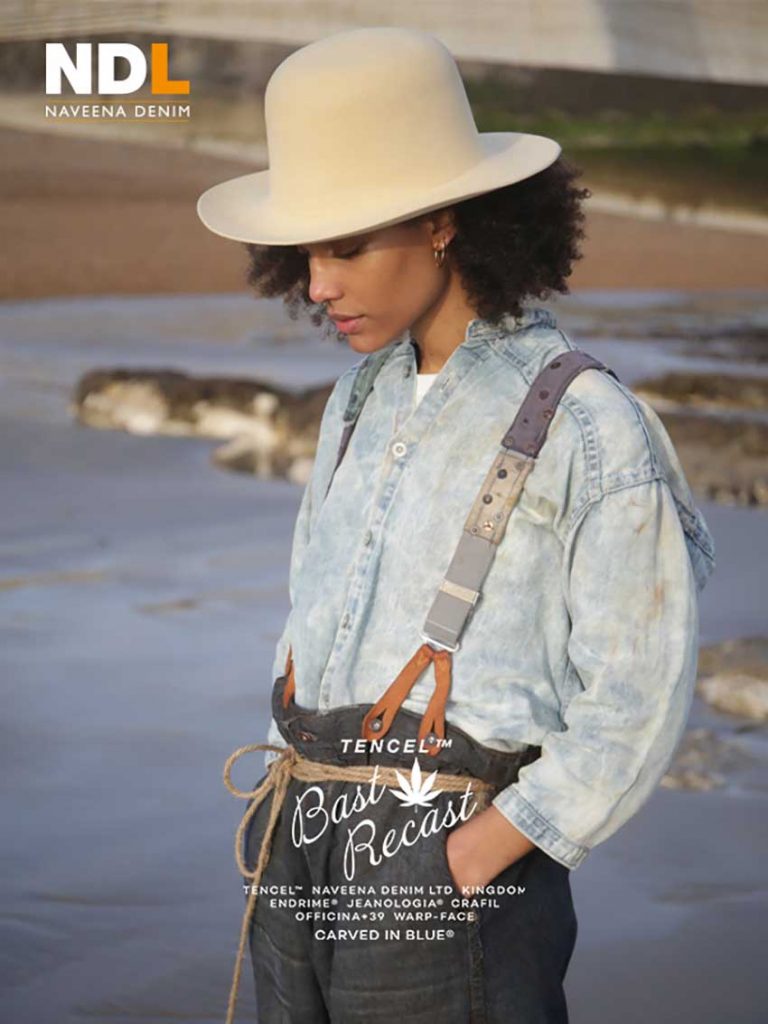

A conventional denim manufacturing process is an environmental catastrophe due to its extensive use of water, energy, and other resources. Our fabric innovations and products are a testament to our goal of going carbon-neutral. From the spinning of fibers to the denim finishing processes, we have taken various sustainability initiatives to create low-impact denim. Our products emphasize the concept of circularity and biodegradability by providing an end-to-end solution in denims.

Our investments in sustainable G2 Dynamic Technology by Jeanologia have helped us save 75% of water and chemicals compared to conventional denim finishing. We are using natural and regenerated fibers in our collection replacing the conventional synthetic-based fibers that are considered to be the major cause of accumulating the landfill and polluting marine life.

E.E: What are the ranges of products?

R.I: We offer a variety of fabrics with a personalized approach tailored to the brand’s needs.

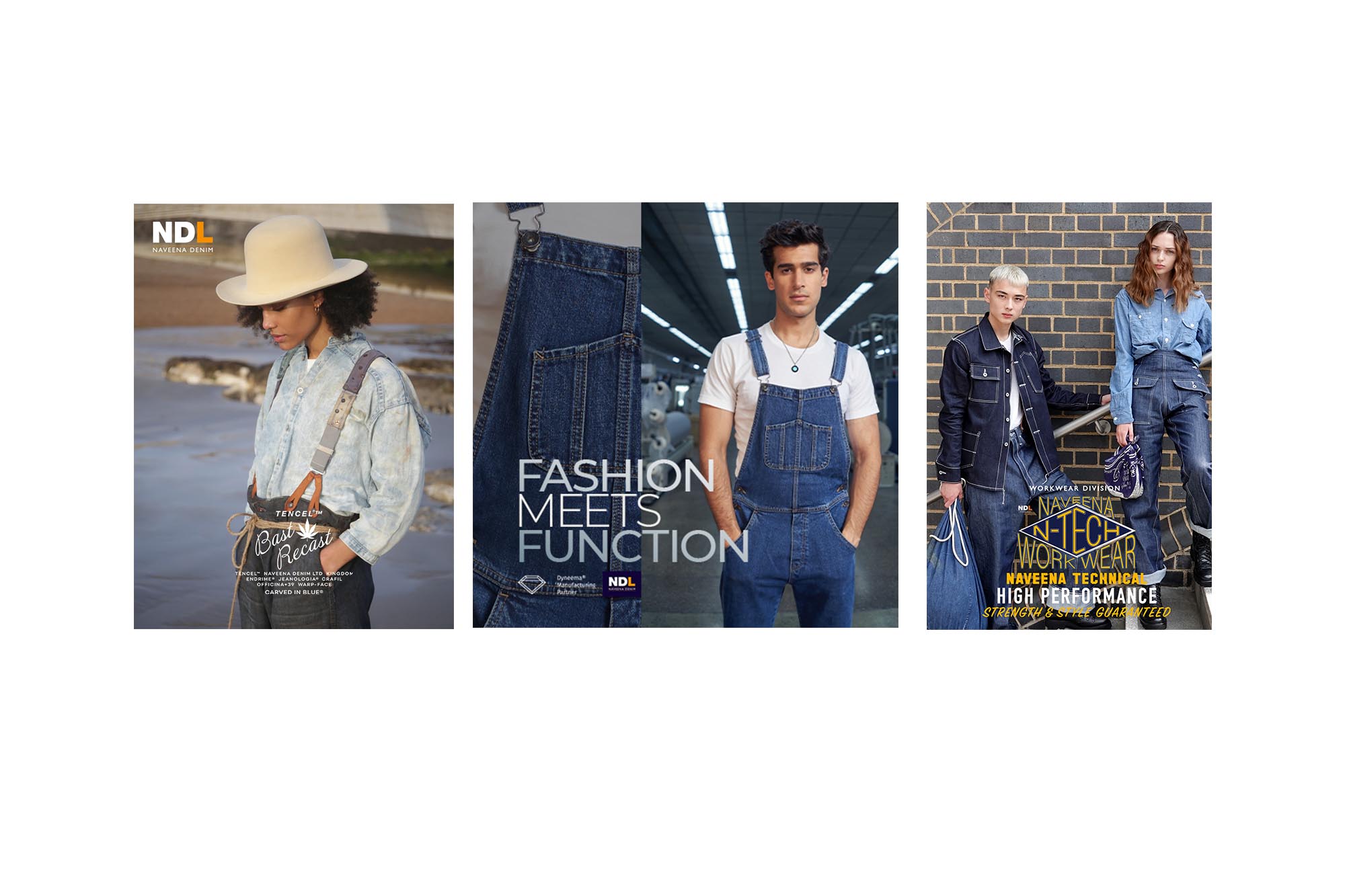

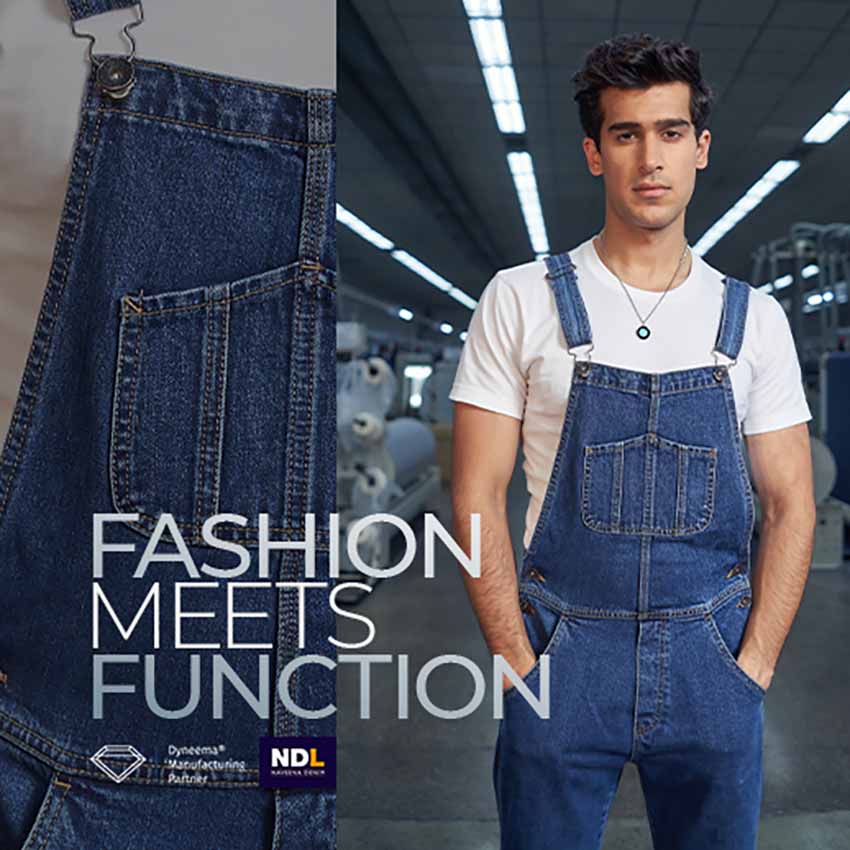

From natural fibers like Hemp, Cotton, Linen and Wool to regenerated fibers like Lenzing Tencel and Refibra, our products are developed according to the latest trends in denim fashion. The versatility in manufacturing denim has enabled us to weave fabrics including the world’s softest fiber Miyabi by Mitsubishi to the world’s strongest fiber Dyneema by Avient which is 15 times stronger than steel.

Dyneema Denim

We specialize in constructing fashion denim for ramping up the style quotient with fabrics characterizing functional attributes.

E.E: At what stage is the market where you are currently active?

R.I: The denim industry has evolved from the destructive part of denim manufacturing to conscious innovations. The key ingredient in denim is to create low-impact jeans with newness. Recent years have seen an increase in the awareness of sustainable development. This concept of eco-friendly manufacturing has enabled us to innovate fabrics considering the environmental aspect.

The evolution of workwear jeans has also garnered significant importance in the market. Designed to meet the demands of workwear, our fashion-crafted denim collection: Fashion meets Function and Strength N Style combines functionality with style to make sure to slay your day.

E.E: What can you tell us about market trends?

R.I: The denim trends in the market has changed drastically over the past few years. The pandemic (Covid) was a real game changer as we witnessed the shift in the buying behavior. Transparency has become an imperative. Consumers now prefer denim fits that provide a core comfort with the authentic character. Comfort stretches have taken over skinny jeans. Straight leg styles have continued to dominate on the runway and on social media while the relaxed fit is key right now.

E.E: What are the most innovative products marketed?

R.I: NDL is recognized as a mill of innovation and that’s what keeps us going. Through collaborative efforts with brands and supply chain partners, we have developed conscious denim collections that are unique in construction and are sustainably dyed using eco-friendly dyeing techniques. Our recent capsule collection with a German based brand Tom Tailor is designed using a natural fiber(Hemp) to reduce the dependency on cotton and other parameters required for its cultivation.

Collaboration drives NDL’s Hemp Denim – insidedenim

E.E: What estimations do you have for the rest of 2022?

R.I: This year and in the years ahead, eco-consciousness will be the concern for everyone. The adaptation of fast fashion has created an awareness among the Generation Z to focus on the shelf life of the garment/ jeans rather than just being a fashion symbol.