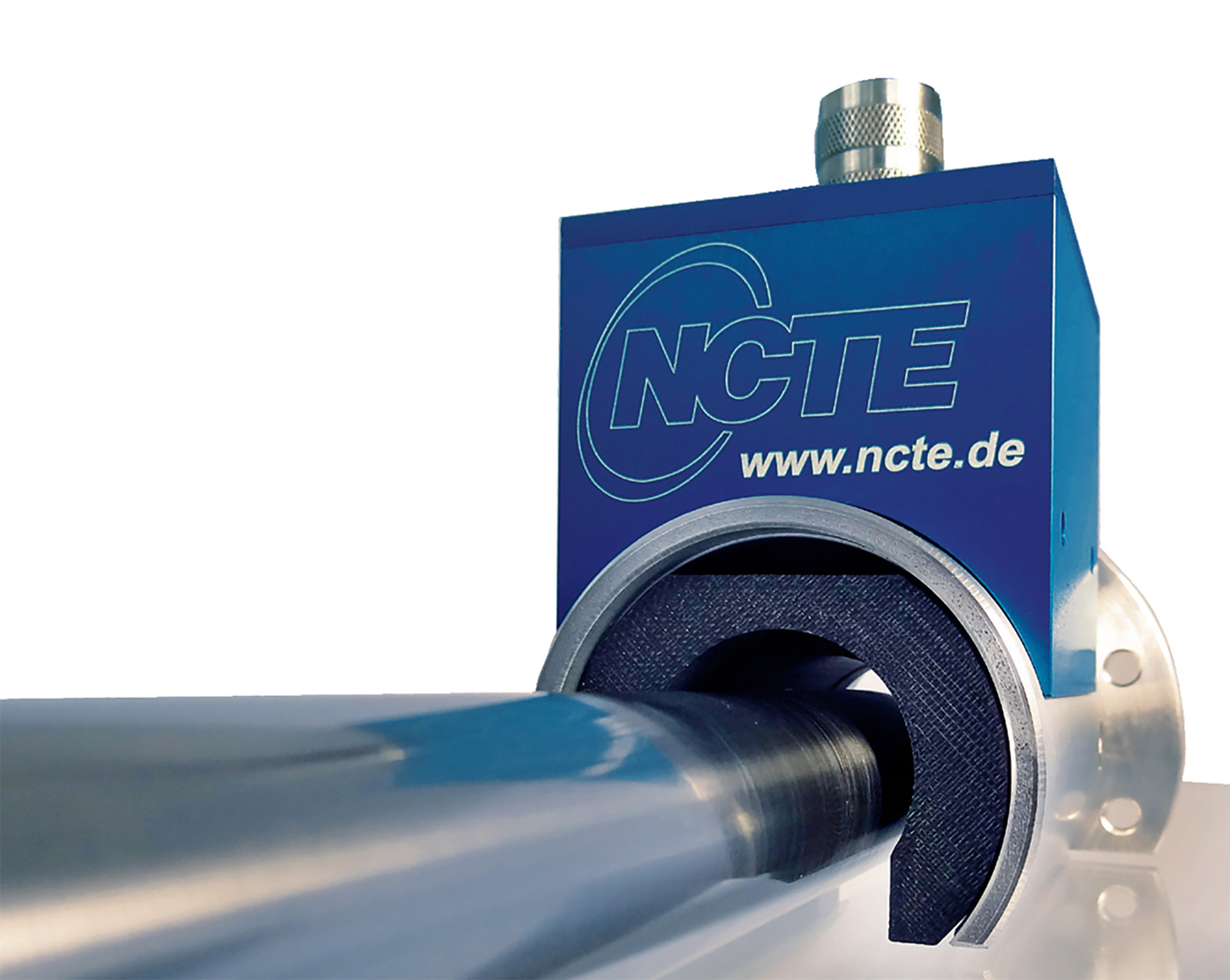

NCTE is a specialist in non-contact sensors for measuring torque, force, shear, speed, bending and position. NCTE uses a patented technology of elastic magnetostriction: By magnetization, metal can be made the “transmitter” of a sensor. A “receiver” detects magnetic field changes without contact and evaluates them in real time.

Founded in 2003 as a development company, NCTE has since evolved into a manufacturing technology innovator with series products. The globally active company develops and manufactures at the company’s site in Munich, Germany. Customers include KTM, TQ, Fazua and Schaeffler.

Easy Engineering: What are the main areas of activity of the company?

NCTE: With our sensor solutions, our customers from e-mobility, agricultural technology and Industry 4.0 leverage new potentials of their machines and products. Wherever forces are at work, we help to collect data in a simple way and in real time. This makes applications sustainably intelligent and conserves resources.

Our sensors measure forces completely contact-free. How does it work? Through the physical principle of magnetostriction: we introduce a long-term stable magnetic field into the shaft during the production process and measure the change in the magnetic field. This means that the NCTE does not need slip rings or telemetry when integrating sensors, does not need to be readjusted and operates completely wear-free. The sensors provide accurate measured values even with strong vibrations, temperatures up to 85 °C (185 °F) and speeds above 40,000 rpm. Even oil and water do not affect operation. In series products, the sensors can be operated over their entire service life. For the customer, the total cost of ownership drops significantly.

As a pioneer in the field of non-contact torque measurement, we are driven by constant innovation. We implement customer requirements in record time and are on hand as a realization partner with our know-how when it comes to designing new, customized applications.

E.E: What are the ranges of products?

NCTE: Our sensor technology supports sustainable mobility in e-bikes, ensures more efficient use of resources in agriculture and Industry 4.0, and strengthens the health and well-being of society in fitness equipment. The product portfolio includes standard products and customized sensor solutions, both in one-off production and for series.

We offer diverse sensor solutions that can be used anywhere from test benches to medical technology to highly complex industrial products.

We love new challenges and see ourselves as a partner to our customers. We work closely with them to achieve the best result together. Our NCTE team of experts then interacts with the customer to develop proposed solutions specifically for their application. We also help to further process and use the measured data – for example, to avoid overloads and thus expensive maintenance in machines.

We manufacture our non-contact torque sensors in the highest quality “Made in Germany”. This means they operate wear-free in the long term and can be used over the entire service life of the application. As long as the e-bike is running, the tractor is pulling its tracks and the end-of-line test lasts – our sensors reliably provide data where no one else can measure.

E.E: At what stage is the market where you are currently active?

NCTE: At the beginning of smart machines and products there is always a sensor, because only with a sensor data can be recorded and actions executed. With our sensor solutions, our customers from e-mobility, agricultural technology and Industry 4.0 develop their machines and products. Wherever forces act, we help collect data in a simple way. We make machines and products smarter. And without developments in sensor technology, many product innovations of our time would be inconceivable.

For decades, the market and application areas for torque and force sensors have changed little. In recent years, new requirements have arisen, and these require new innovative sensor solutions, even in large quantities. Conventional torque sensors based on strain gauges still have their justification, for example when it comes to very precise measurement in test bench applications. However, they are very expensive to purchase and maintain, which in turn prevents high-volume use in series production and thus does not meet the new requirements.

Likewise, previous technology is reaching its limits in Industry 4.0, Big Data applications and smart series products. With new technology, there is a solution to this problem that is suitable for series production: our non-contact torque sensors based on inverse magnetostriction. Magnetic technology is already used in a wide range of smart products such as e-bikes, for torque measurement in robotics or in drive shafts in industry. It represents both a non-contact and compact solution that is up to a factor of 10 more cost-effective than other measurement methods. The market for our sensor technology still has great growth potential.

E.E: What can you tell us about market trends?

NCTE: As a pioneer in the field of non-contact torque measurement, we have important know-how. In addition, we are driven by constant innovation and, together with our customers, we always want to develop new solutions. Especially with megatrends such as the industrial Internet of Things (IoT) or e-mobility, the potential applications for our technology are only just beginning. Internationally, NCTE can still greatly expand its presence. We will do this through internationalization and by focusing on sustainable future markets such as e-mobility, agricultural technology and Industry 4.0. In addition to Europe, our regional focus will be on China and North America.

E.E: What estimations do you have for 2021?

NCTE: Over the past few years, NCTE has developed from a startup into a manufacturer, specialist and innovator with series production. In the process, average sales increase of over 20% have been achieved. This year, we want to continue to grow significantly in our core segments. To this end, we are expanding both direct sales and our international dealer network. Our goal for our sustainable technology is to be established with all global players and OEMs. When someone thinks of torque sensors, they should immediately think of NCTE.

NCTE AG

Ralf Müller

+49 (0)89 665 619 – 44