Nel PreTech Corporation is a 3D & CT Scanning Laboratory offering value-add engineering and metrology services.

Interview with Dave Nelson, President of Nel PreTech Corporation.

Easy Engineering: What are the main areas of activity of the company?

Dave Nelson: We operate as an end-to-end industrial scanning, metrology, and engineering services partner. The main areas of activity are 3D industrial scanning, x-ray computed tomography, reverse engineering, CMM inspections, and advanced NDT services. We set ourselves apart from typical inspection labs by focusing on our people who are trained and trusted experts in the fields of physics, metrology, and mechanical engineering. A quality process accredited to ISO 17025 protects the customer and our advanced technology platform of performance driven technologies provide them the very best in metrology and measurement related services.

E.E: What’s the news about new services?

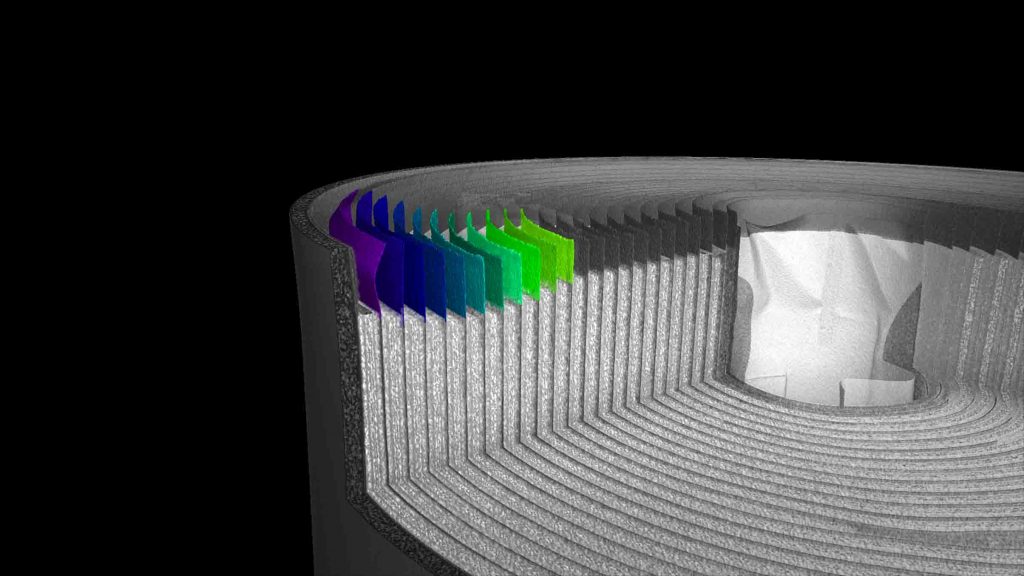

D.N: Computed tomography (CT) scanning is a technology disrupter and it is dramatically changing the way products are developed, manufactured, and brought to market. Like anything else, to realize the full benefit, it requires thoughtful integration and the right people to execute and manage it.

E.E: What are the ranges of services and technologies used?

D.N: The range of services are widespread and can include flaw detection, failure analysis, assembly accuracy, capability studies, porosity analysis, wall thickness analysis, dimensional inspection, layouts, color maps, STL’s, engineering support, material analysis, process optimization, and reverse engineering. From an environmentally controlled lab to cutting-edge equipment like the Zeiss Metrotom 800, Zeiss Metrotom 1500, and the ATOS Q structured blue light scanner, we’re able to help manufacturers improve product quality, manufacture better, and reduce recalls.

E.E: At what stage is the market where you are currently active?

D.N: The computed tomography (CT) scanning and 3D scanning market is well past emergence and, in my opinion, at the beginning of its rapid growth stage.

E.E: What can you tell us about market trends?

D.N: Broad market acceptance of industrial CT scanning and 3D scanning is gaining traction and companies are slowly minimizing the role of, replacing some, and/or completely abandoning older more traditional product measurement/testing techniques.

E.E: What are the most innovative services marketed?

D.N: The back-end services post CT scan are the most innovative. Major advances in software processing power, built in analysis functionality and automation are creating seemingly “Sky is the limit” service offerings. Post CT scan services that allow for the analysis of internal material structures are at the top of the list such as porosity, FEA analysis, fiber orientation and a host of related offerings.

E.E: What estimations do you have for 2023?

D.N: Widely recognized economic headwinds (ex: inflation, interest rates, supply chain problems, slower corporate earnings, rising cost of business etc…) are creating near term challenges. These challenges are somewhat mitigated by our aggressive marketing and new client on-boarding. However, to a larger degree, innovative and disciplined companies will continue to embrace game changing technology expenditures for longer term health. Also, emerging markets such as EV and additive manufacturing will also enter the 2023 market in a bigger way to help offset many of the short-term economic challenges.