With over 40 years’ experience in the mitigation of uncontrolled static discharge, Newson Gale empowers people to understand and control electrostatic ignition hazards; specializing in the design, development and manufacture of hazardous area certified static grounding systems, devices and accessories. The head office and manufacturing facility are based in Nottingham, UK, with subsidiaries in USA, Germany, Singapore and China.

As of 2016 Newson Gale became a part of Hoerbiger Safety Solutions and now operates through channel partners in 53 countries, providing a strategic commercial network that allows shipping worldwide to over 100 countries.

From the loading of road tankers to the emptying of hand-held metal cans, the company has a solution for a broad range of EX/HAZLOC processes that are capable of generating static electricity.

Interview with Damian Gwardecki, Regional Sales Engineer Europe & Andy Farmer, Internal Sales at Newson Gale.

Easy Engineering: What are the main areas of activity of the company?

Damian Gwardecki & Andy Farmer: Newson Gale designs and manufactures a wide variety of static control equipment. Working together with industries where hazardous area (explosive atmosphere) applications are commonplace, such as: paints & coatings, pharmaceutical, oil & gas, specialty chemicals, food processing & environmental services. Our mission is to guide our customers to making an informed decision on the best practice solution with reference to IEC TS 60079-32-1 and NFPA 77 industry standard recommendations and guidance for mitigating electrostatic hazards.

E.E: What’s the news about new products?

D.G & A.F: Earth-Rite® DGS – Dual Grounding System

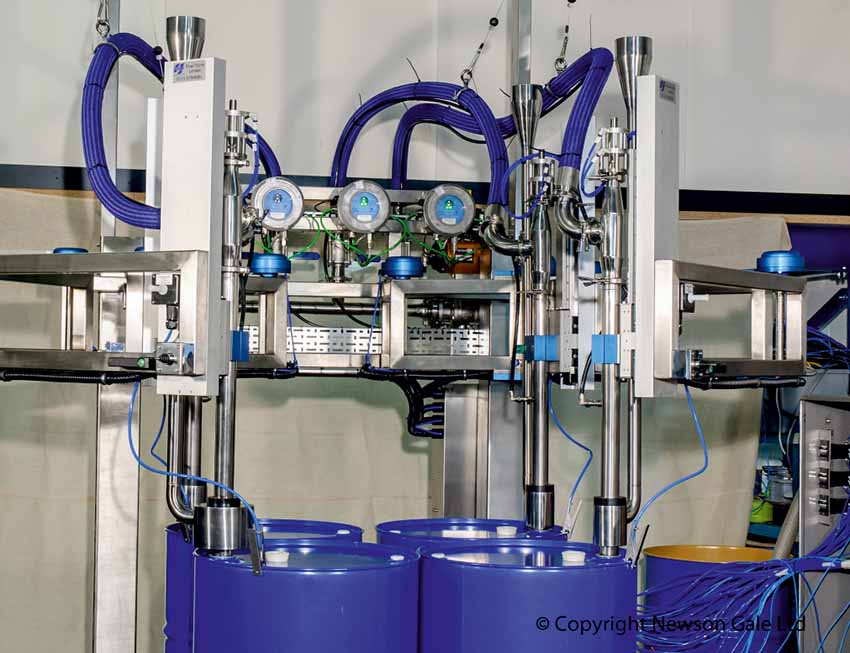

In hazardous environments, simultaneous processes requiring the transfer of flammable or combustible materials are a regular occurrence. Newson Gale launched the Earth-Rite Dual Grounding System (DGS), combining visual indication, interlocking capabilities, and two intrinsically safe monitoring circuits for grounding operations in hazardous area industries.

The system allows operators to ground and continuously monitor two items of metal conductive plant equipment concurrently, such as two bulk transportation vehicles or other metallic vessels like Ex IBCs and metal drums,

Break Away Connector (BAC)

In 2021 Newson Gale released the new Break-Away Connector for use with our patented Earth-Rite® II RTR road tanker recognition and static earth monitoring system.

The Break Away Connector (BAC) fits in-line with the grounding clamp and cable. If the road tanker is driven off prematurely, the grounding clamp and the plug half of the Break Away Connector (BAC) assembly separates from the remaining socket and cable, thus mitigating further damage to the installation. This means that only the clamp and BAC assembly need to be replaced to enable the grounding equipment to be up and running again quickly.

Magnetic Clamp (VESX50-IP)

Newson Gale have also designed a two-pole grounding connector that utilises the power of magnetism and the reliable strength and sharpness of tungsten carbide teeth to provide a strong low-resistance connection (≤10 Ohms) to any ferrous metal surface e.g. body of a drum, tote, hazardous area suitable IBC, etc. This will allow ferrous metal drums to be filled, the cover fitted, complete with extract connection over the open top, and still be grounded with the two-pole magnetic grounding clamp.

Fully compatible with the Newson Gale Bond-Rite® and Earth-Rite® range (PLUS, DGS, & MULTIPOINT II) of monitoring systems that provide the customer with visual indication and interlock capability. By installing this clamp and these systems the end users are able to comply with the international standards, guidance and/or recommended practices IEC TS 60079-32-1, NFPA77 and API RP 2003 in achieving a metal-on-metal to ground connection of ≤10 Ohms before the process starts and therefore are able to mitigate static build up, and auto-ignition within a flammable atmosphere.

E.E: What are the ranges of products?

D.G & A.F: The Cen-StatTM range of ATEX & FM-approved clamps and cables offers reliable mechanical static earthing measures, without visual indication or interlocks. These pressure-type clamps have sufficient strength to penetrate any protective coating, rust, or spilled material to ensure contact with the base metal with an interface resistance of less than 10 Ohms.

The stainless steel (SS 304) body provides optimum levels of mechanical protection whilst retaining a high level of chemical resistance. Stainless steel is also highly resistant to rust, preventing the possibility of thermite reactions during contact with aluminium.

The Bond-Rite® Range provides enhanced safety and security by continuously testing the connection of the clamp to the container or other conductive item of plant in a complete loop made through the designated grounding point, to a 10 Ohms threshold. 6

The Bond-Rite is specifically designed for lower-risk processes in areas where:

- Interlocking is not possible or required

- Operation is manual, or operators are present during the process

- Process times are minimal (not permanent)

The intrinsically safe circuitry of the Bond-Rite® Range allows flexible installation and usage throughout all zones/classes & divisions within hazardous area industries enabling each product to achieve a high equipment category rating for Zone 0 / Class 1, Div. 1.

Options for both mains-powered and certified 9v battery-powered system are available.

The Earth-Rite® Range: all systems in this range can interlock with process control equipment (PLC/SCADA, etc) and upon detecting a non-permissive monitoring signal (above 10 ohms grounding circuit) energise their relays, allowing the contacts to switch position, breaking a control circuit and preventing further accumulation of hazardous static charge within an EX area.

Systems in this range include:

Earth-Rite® PLUS – For use on Railcars, LACT units, Skids, Portable metal vessels / drums, hazardous area suitable IBCs.

Earth-Rite® FIBC – For use on Type C FIBC bags to monitor the continuity through the static dissipative threads.

Earth-Rite® RTR – For road tanker earthing and capacitance detection, installed on site.

Earth-Rite® MGV – For mobile verification of a road tanker / vacuum truck, mounted on the vehicle.

Earth-Rite® DGS – As per Earth-Rite® PLUS, where two separate items require independent monitoring and interlock.

Earth-Rite® MULTIPOINT II – Multi-channel monitoring, with 8 separate monitoring channels and interlocks, with additional group relay. For use on multiple portable items, or larger inter-connected assemblies such as industrial sieves, micronisers, etc. with potentially isolated components.

E.E: At what stage is the market where you are currently active?

D.G & A.F: COVID19 Pandemic together with the conflict in Ukraine has had an affect on business but the markets where we are active are currently growing.

E.E: What can you tell us about market trends?

D.G & A.F: Our team around the world have conducted training sessions and we can now start to see that the risks associated with static electricity are considered very serious. We can see the increasing interest in our safety solutions which has led to many more sales of static earthing monitoring systems.

E.E: What are the most innovative products marketed?

D.G & A.F: Over the past year we have seen a massive interest in our Earth-Rite® II MULTIPOINT II, a multi-channel ground monitoring system. In 2022 Newson Gale released the Earth-Rite® DGS, a dual grounding system which enables the end user to simultaneously monitor up to two conductive plant items at the same time.

E.E: What estimations do you have for 2022?

D.G & A.F: 2022 looks very positive for Newson Gale and we are expecting further growth in Europe, Africa and Asia.