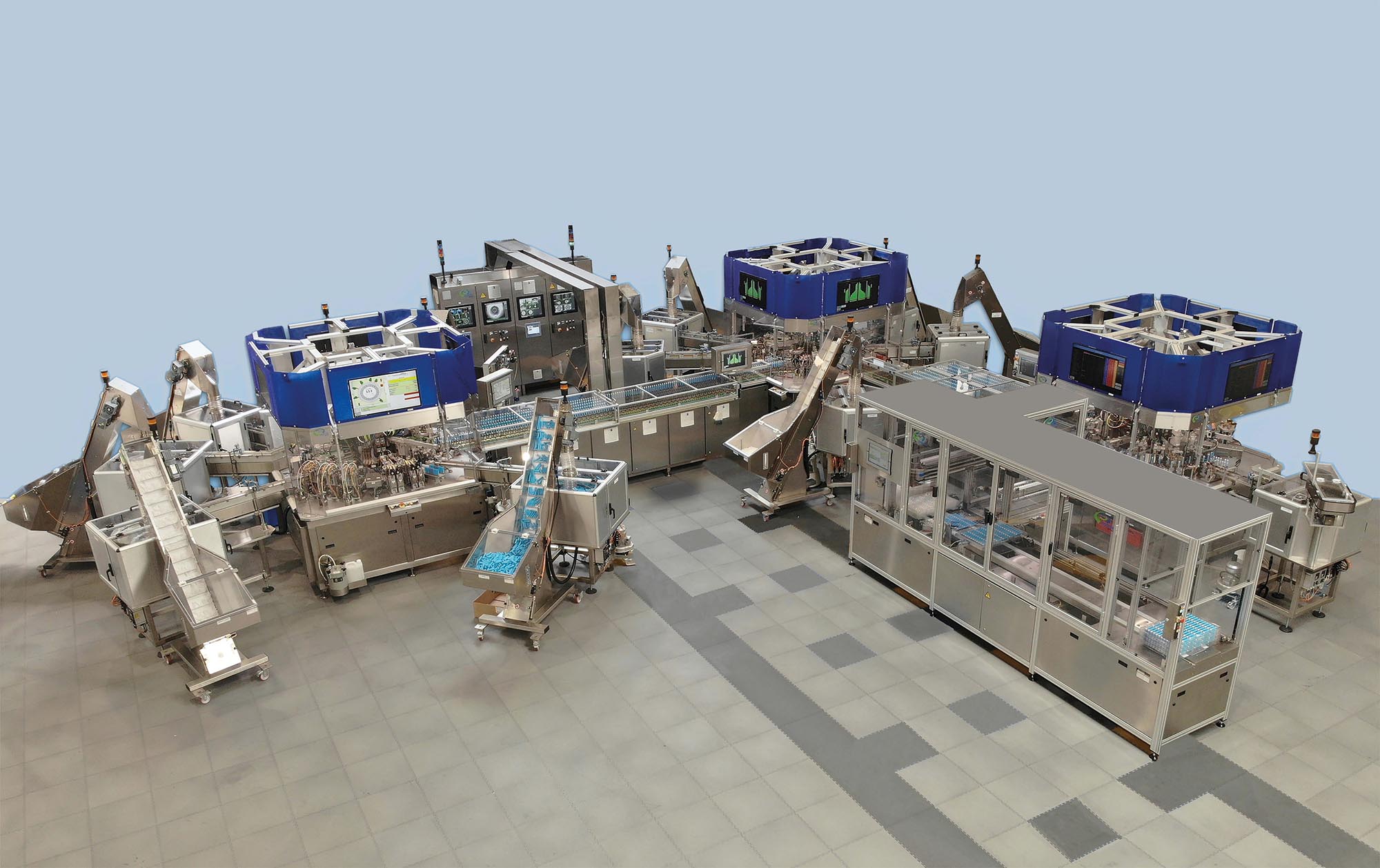

Neyret Group designs and manufactures bespoke high-speed assembly machines. Over the course of more than 35 years as a leader in assembly machines, the company has developed off-the-shelf processes and solutions always driven by constant innovation and tailored to each customer’s individual needs.

Interview with Bruno Neyret, CEO of Neyret Group.

Easy Engineering: What are the main areas of activity of the company?

Bruno Neyret: Mainly, Neyret Group supplies high-end assembly & testing solutions for healthcare, automotive, cosmetic and energy industries. However, we are not limited by any particular industry sector and are able to tackle various projects, thanks to our in-house R&D department and extensive experience in automation solutions.

“Product defines the technology” is our company philosophy. For that reason, everything starts from engineering a complete machine or an assembly line. We develop from A to Z an optimal assembly process granting 100% compliant assembled products and a high production output.

Neyret Group develops and integrates mechanical assembly processes, dosing, gluing, welding, printing and labelling stations. These operations may be carried out by manipulators or robots and their quality is necessarily controlled by sensors and cameras as well as the quality of the components and products

E.E: What’s the news about new products?

B.N: This year Neyret Group launched an innovative printing solution for pharmaceutical industry offering high quality and durable printing. This digital printing machine meets medical grade requirements and is much easier in use than standard pad printing machines.

The main advantages of Neyret Group’s machine are the following:

Quick changes. No printing plates needed; files are sent directly to the printer.

Reduced downtime. First, pallets of magnetic conveyors can be added or removed at any time with no tools, every pallet has its unique identification number and is recognized automatically. Second, the machine relies on 4 colors ink cartridges with an automatic purge and does not require any specific ink preparations. Thus, saving a significant amount of time.

This digital printing solution can be completed by assembly processes and adapted to other industrial applications. To learn more about it, watch the following video

E.E: What are the ranges of products?

B.N: Neyret Group have expertise in building index motion and continuous motion assembly machines and have a large machine range starting from pilot machines:

Pilot machine may be used during clinical test stage and allow derisking of all critical steps of the assembly process.

Semi-automatic machine is intended for low and medium production volumes up to 800 products per hour. Parts can be fed manually by operators or automatically with feeder bowls.

Flexible machine is designed for multiple variants assembly thanks to easily interchangeable tools, flexible machines assemble up to 2500 products per hour.

Fully automated assembly machine structure depends a lot on the final product and can be built on different platforms: continuous motion machine (up to 60000 products per hour) or index motion machine (up to 14400 products per hour) mount on turning table or magnetic linear conveyor.

To download our detailed machine presentation with assembled product examples, please follow the link https://www.neyretgroup.com/wp-content/uploads/2021/09/machine-range-overview.pdf

E.E: At what stage is the market where you are currently active?

B.N: The assembly machine market is growing extensively and the demand for automation solutions is actually rising. Most of our clients manufacture medical devices and automotive components, these products have stringent quality standards and should pass various tests in order to ensure final users’ safety. It is barely possible to achieve required quality level only with manual assembly and control. Moreover, demand on this kind of products grows day by day and manufacturers should also be able to sustain high production volumes. High-speed automation solutions resolve both of these challenges and offer to industrial manufactures complete peace of mind, thus effective assembly systems are in great demand.

E.E: What can you tell us about market trends?

B.N: During last years we faced a lot of unforeseen events that affected our lives in a certain way but especially the industrial world. Today every company should be flexible enough to see new opportunities and continue serving their clients, assembly machines manufacturers and their client are not an exception.

Above all, we see that especially now our clients and prospects are looking for a reliable partner able to lead complex automation projects to a successful completion.

Certainly, we see a diversification strategy in our clients approaches, most of manufactures built multiple production sites in order to minimize geopolitical risks. Production plants are mostly located in countries closest to final users, that is so important to keep continuous supply under any circumstances.

Another point to note, more companies start to invest in high-speed automated machines and prefer them to cheaper equipment with smaller volumes. Due to increased raw materials prices, both manufacturing and equipment cost rose, and today it becomes hard to sustain the same profit and growth levels without revising production efficiency and investing in sustainable solutions.

E.E: What are the most innovative products marketed?

B.N: Flexible machines to assemble various variants of products in order to match the market demand, that requires lower batches but still at high speed to minimize cost. Automotive industry and cosmetic/dispensing are that kind of market asking for agility. Neyret Group has produced such kind of machines with feeding vision tracking and built-in adaptative toolings/processes.

E.E: What estimations do you have for the rest of 2022?

B.N: We are constantly developing our group and expanding our capabilities and our team, in last five years we grew five times and went from 9M€ turnover to 49M€. But this year we are particularly focused on a company that have recently joined Neyret Group, Franklin Automation. It is a family company based in the USA, Illinois. Franklin Automation is specialized in index assembly machine manufacturing and you can meet them in person at Assembly Show in Rosemont on October 25-27. We would be glad to see you there!