Nilos GmbH & Co.KG is a well-established manufacturer and service provider in the field of conveyor technology, wear protection and rubber adhesive technology. As the pillars of the organization, people and culture bring their customers and partners the great benefit of a single-hand solution for the tried and tested products and services mainly made in the EU, which they are constantly expanding with innovative solutions.

Easy Engineering: What are the main areas of activity of the company?

Nilos: Nilos supplies customer-oriented solutions and additional products for conveyor belt systems and components with high wear. We find our most important markets in plant construction, mining, power generation, cement and aggregate industry, in transshipment ports, but also in shipbuilding and agriculture.

The safe and constant operation of conveyor systems is of great importance for production in any industry. The system solutions from Nilos ensure the safe operation of these conveyor systems from the moment of installation to the regular replacement of certain components, supported by competent advice and active support in the daily maintenance of the systems by our trained service staff.

The longevity of our products for the conveyor industry and in general wear protection increase the service life of system components, whereby the individual components of the system solutions are perfectly synchronised. General applications are just as much a focus of our developments as special customer-specific needs.

E.E: What’s the news for 2020 about new products?

Nilos: Before the end of the year we will add a new development to the expanded capacity of our rubber-ceramic pulley lagging production that will change the market for wear-resistant drum laggings.

E.E: What are the ranges of traded products?

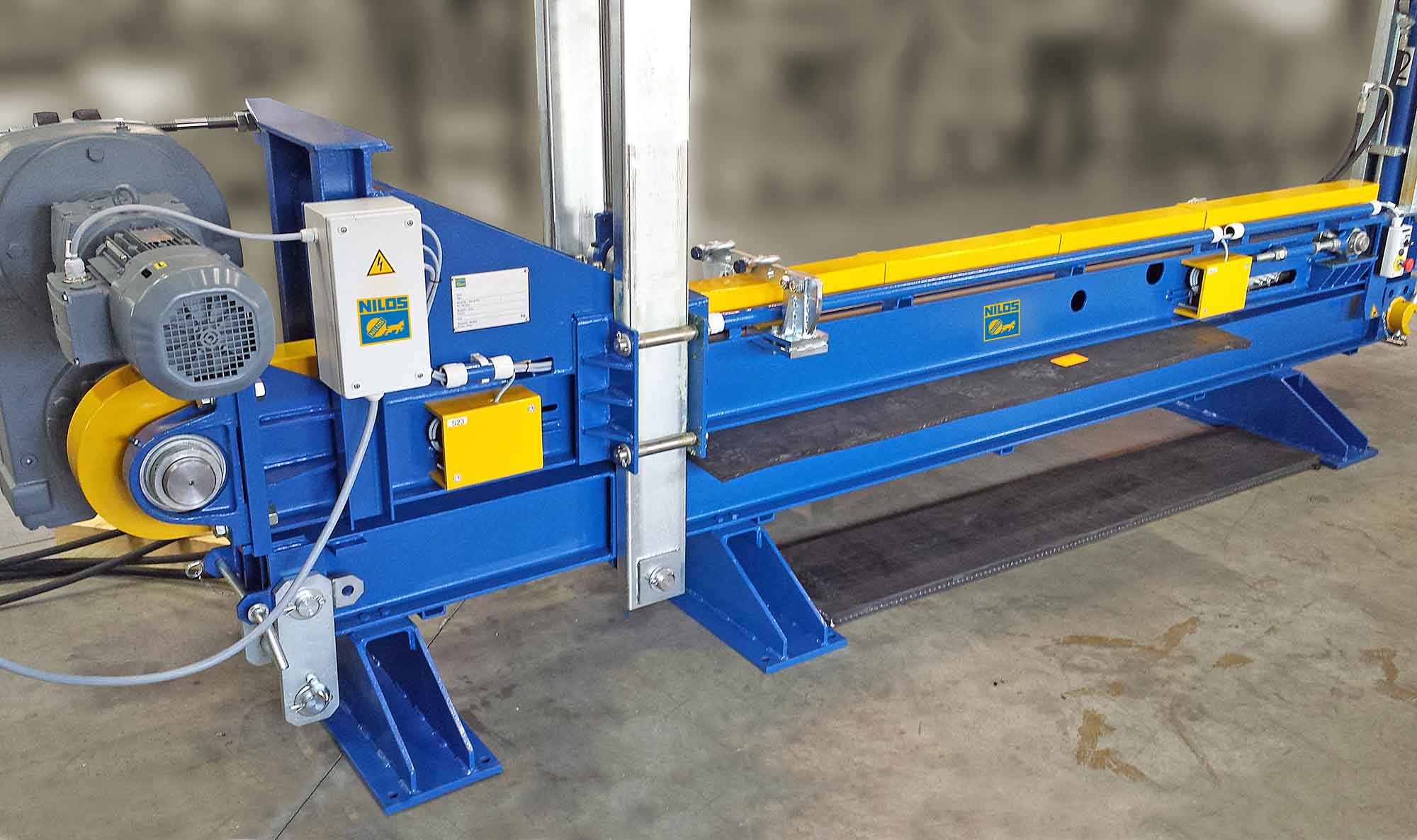

Nilos: We offer a complete range of conveyor system components, ranging from high-quality portable vulcanizing presses to endless splicing material for conveyor belts, all of which are developed in-house. A professional in-house R&D department ensures fast development. More than 95% of our processed materials are produced in our own plant in Germany.

Standardized idlers, drive pulleys and corresponding wear-resistant pulley laggings are complemented by various rubber adhesive systems that harmonize perfectly with our special rubber-metal adhesive layers and thus guarantee a long-lasting operation. Wear protection material made from high-quality rubber and state-of-the-art ceramic components are specifically designed to guarantee the maximum service life of the conveyor systems. In addition, we supply our materials flame retardant or self-extinguishing.

The tools required for the safe installation and processing of system components support our customers as well as our service staff with the assembly of the system solutions. The focus is also on sustainability, which with the Rotocut steel cord cutter has reached new dimensions in the safe and environmentally friendly cut of steel cord conveyor belts.

E.E: At what stage is the market where you are currently active?

Nilos: The resources of our planet will continue to have a far-reaching influence on the sustainability of everyday life in the future. From a global perspective, mining is just as important as agriculture.

We see great development potential in our markets, even if an end is in sight, especially for coal mining in the domestic market. It is therefore particularly important for medium-sized and small companies in Europe to position themselves more broadly for the future.

With decades of experience, Nilos is constantly working to continue providing our customers with future-oriented products with European quality. To this end, Nilos and all linked partners face the ever-increasing demands of sustainability, which is already reflected in the use of green energy.

E.E: What can you tell us about market trends?

Nilos: Growing interest in battery technologies with the still necessary lithium extraction and many other minerals as well as the steadily growing recycling industry are subject to enormous pressure for the use of operationally safe and at the same time environmentally friendly technologies and products in order to ensure the transportation of bulk materials also in the future.

The situation-related breaks in supply chains have just shown how important it is to have one’s own quality-related in-house design and manufacturing, and we are proud to guarantee our customers the necessary availability at all times. More and more of our customers have already realized this and are demanding the available European quality in order to ensure their own productivity.

E.E: What are the most innovative products marketed?

Nilos: As a market leader in the field of portable vulcanizing presses with our mechanical engineering, we have introduced a number of innovative products to the market in recent years, such as the Rotocut for safe cutting of steel cord conveyor belts. With the RBK-R70 rubber-ceramic pulley lagging, we already have a market-leading champion who will receive additional support soon. The made in Germany high-class splicing materials fit nearly all conveyor belt types around the world and have also convinced many international customers to source from NILOS.

E.E: What estimations do you have for 2020?

Nilos: Even if the pandemic is currently making any forecast difficult, we can already foresee that the consistent expansion of or so called “Nilos and Friends” Network has developed positively for us and our partners. We have expanded production capacities, strengthened existing partnerships, and researched new ones. This will continue to develop beyond the turn of the year. We are excited to be part of the move into the future and create new innovations mixed with proven technologies.