Nowi is a semiconductor company based in Delft, the Netherlands, with sales offices in Hong Kong and California. The company specializes in the design of power management integrated circuits (PMICs) for low power energy harvesting. Nowi was established in 2015 by founders Simon van der Jagt and Omar Link after they completed their Master degrees. The company started with developing sensors, which use energy harvesting to last a very long period of time. Over the last few years Nowi has shifted its focus towards semiconductor chipset design for energy harvesting. Nowi has grown exponentially in a short period of time to establish itself as a budding player in the chip design segment. Its team has grown from a few people to almost 30 employees. With a goal to remove power bottlenecks in large scale IoT implementations, it has partnered up with companies like T-Mobile, Huawei and Telink to develop smart solutions. In 2019, Nowi collaborated with MMT, a Swiss smartwatch module manufacturer to develop a module which does not need to be charged by the consumer.

Easy Engineering: What are the main areas of activity of the company?

Nowi: Nowi is primarily focused on Energy Harvesting technology from ambient sources like solar, vibration and thermal gradient. They design power management ICs for low power applications in the mW range. The main advantages of Nowi’s chipset over competing players in the market are:

- Minimum external components;

- Ultra-small PCB area required;

- Suitable for applications with changing environments due to fast maximum power point tracking.

Owing to these advantages, Nowi enables the use of energy harvesting in industry segments like smart infrastructure, consumer electronics, healthcare, retail etc. The company provides end to end integration support to its consumers curated to their specific needs.

E.E: What’s the news for 2020 about new products?

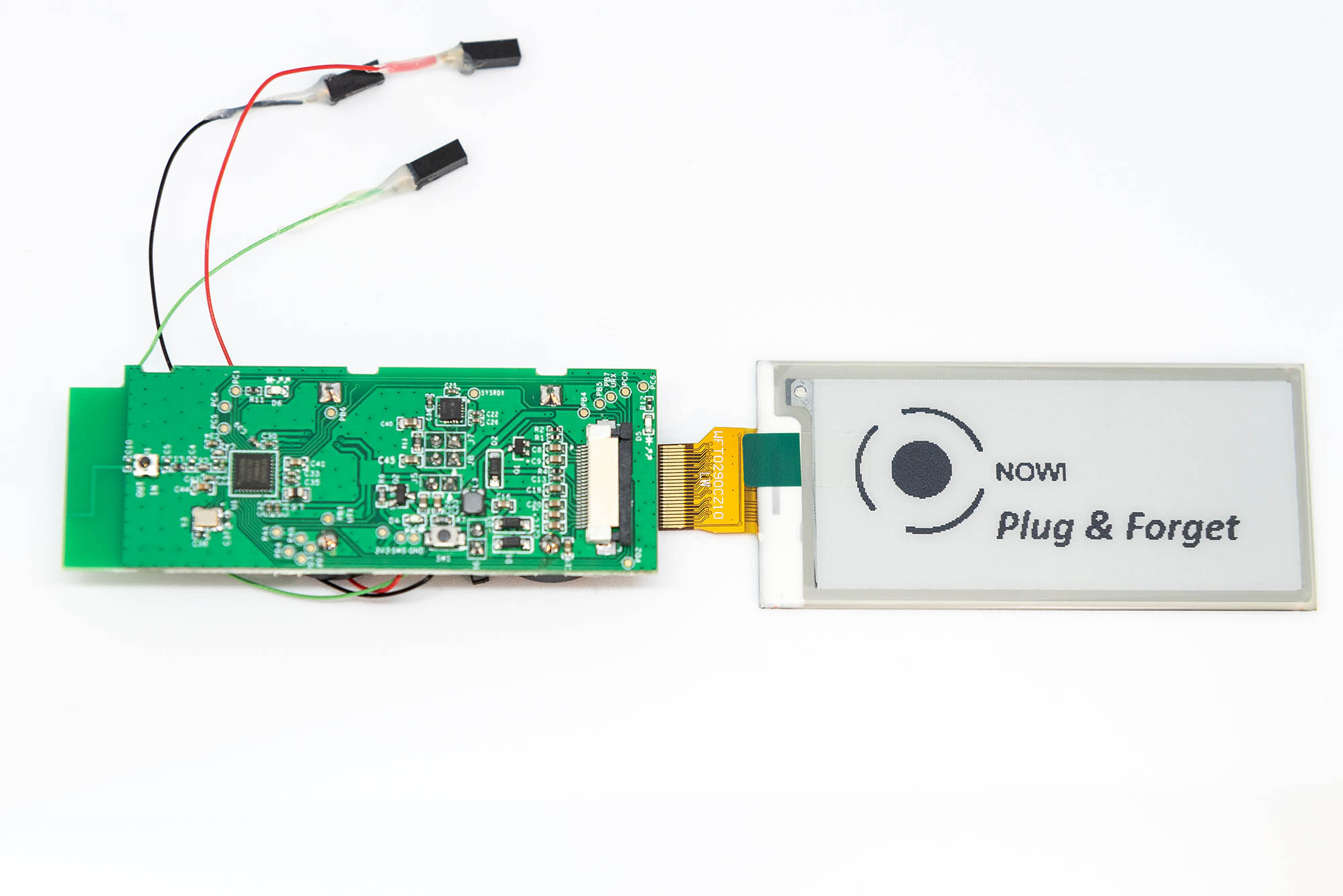

Nowi: Nowi unveiled the NH2D0245, their new PMIC for low power energy harvesting. Production ready NH2 is now available for integrating into customers’ solutions. The new chipset has already found its way into battery free electronic shelf labels by Telink Semiconductor and Hisilicon’s NBIoT module.

E.E: What are the ranges of traded products?

Nowi: The core competency of Nowi lies in PMIC design, and it supports primarily two kinds of customers.

OEMs: The Nowi chipset is provided to OEMs for integrating it into their product. During the integration stage, Nowi supports the OEM by suggesting the right harvesters, batteries and other components suitable for the application.

Chip Manufacturers: Nowi’s chipset design layout is also licenced to semiconductor companies to incorporate it in their SoC.

E.E: At what stage is the market where you are currently active?

Nowi: The industry as a whole is striving towards a greener future, which includes the widespread adoption of energy harvesting. Nowi’s solution is used in various markets such as Smart Infrastructure, Consumer Electronics, Healthcare etc. Some of these markets like retail, consumer electronics and healthcare are very mature and developed, but have started incorporating energy harvesting in their solutions. Other markets like smart infrastructure are currently developing and widely adopting energy harvesting solutions to enable Plug & ForgetTM sensor systems. Nowi is helping the industry to reduce the reliance on batteries and incorporate energy harvesting.

E.E: What can you tell us about market trends?

Nowi: The market is gravitating towards green solutions. Energy harvesting is being accepted across the spectrum and Nowi is enabling this transition. If one looks at consumer electronics, companies are investing in solar powered wearables, remote controls, game controllers. On the other hand, smart infrastructure is highly dependent on energy harvesting to have functioning sensor arrays without interruption. Nowi has partnered up with T-Mobile in the past to install road monitoring sensors in the Netherlands. Critical infrastructure like roads, bridges, commercial buildings cannot be closed off for extended periods for sensor battery replacement. Companies like Huawei, Nokia, Ericson are investing heavily in IoT solutions and developing various network topologies that are independent, energy efficient and can run uninterrupted for many years with energy harvesting. The medical industry has recently started experimenting with energy harvesting in order to enable long lasting sensors for under the skin. Energy harvesting is finding its way into industries ranging from infrastructure, industrial automation, automotive to home automation and consumer electronics.

E.E: What are the most innovative products marketed?

Nowi: There has been a plethora of consumer products utilising energy harvesting. A specific smartwatch that uses the temperature gradient between the user and the environment. The watch then does not need to be recharged and can in theory function without interruption. Another product that caught our attention is the solar energy harvesting multisensor which is touted as the best sensor for smart infrastructure. It is a combination of accelerometer, magnetometer, thermometer, illumination and humidity sensor which functions indefinitely without any battery change required.

E.E: What estimations do you have for 2020?

Nowi: The energy harvesting sector has been gaining pace for quite some time now and it is reaching a tipping point where it is possible to harvest enough energy to power certain sensors and applications. The coming years are going to be interesting for this field when we see widespread implementation of smart infrastructures and automations.