Founded in 1954 in Parma, Italy, OCME is among the most reliable and innovative leaders in automated packaging machinery and solutions. OCME’s productions are designed and manufactured in the Packaging Valley, the land par excellence of the world’s most famous packaging machines. Since 2018, the company has become part of Aetna Group, an end-of-line packaging giant with production facilities in Italy, the United States, Brazil, China and Germany.

The Group is also active with 12 subsidiaries in major business areas, employs more than 1,850 people, including more than 280 technicians engaged in after-sales service, and has a 24/7 service network. It has a turnover of more than 400million euros and invests more than 7% annually in R&D.

Interview with Gabriele Folli, Communication Manager at OCME.

Easy Engineering: What are the main areas of activity of the company?

Gabriele Folli: The Parma-based company’s wide and deep experience in the beverage sector meets all customer needs in terms of quality, advanced technology and flexibility. Whatever the container to be filled – PET bottles, glass bottles, Tetra bricks or cans – OCME is able to find the right solution through a team of engineers who develop tailor-made solutions with the customer, with a view to energy saving, system safety and efficiency.

E.E: What’s the news about new products?

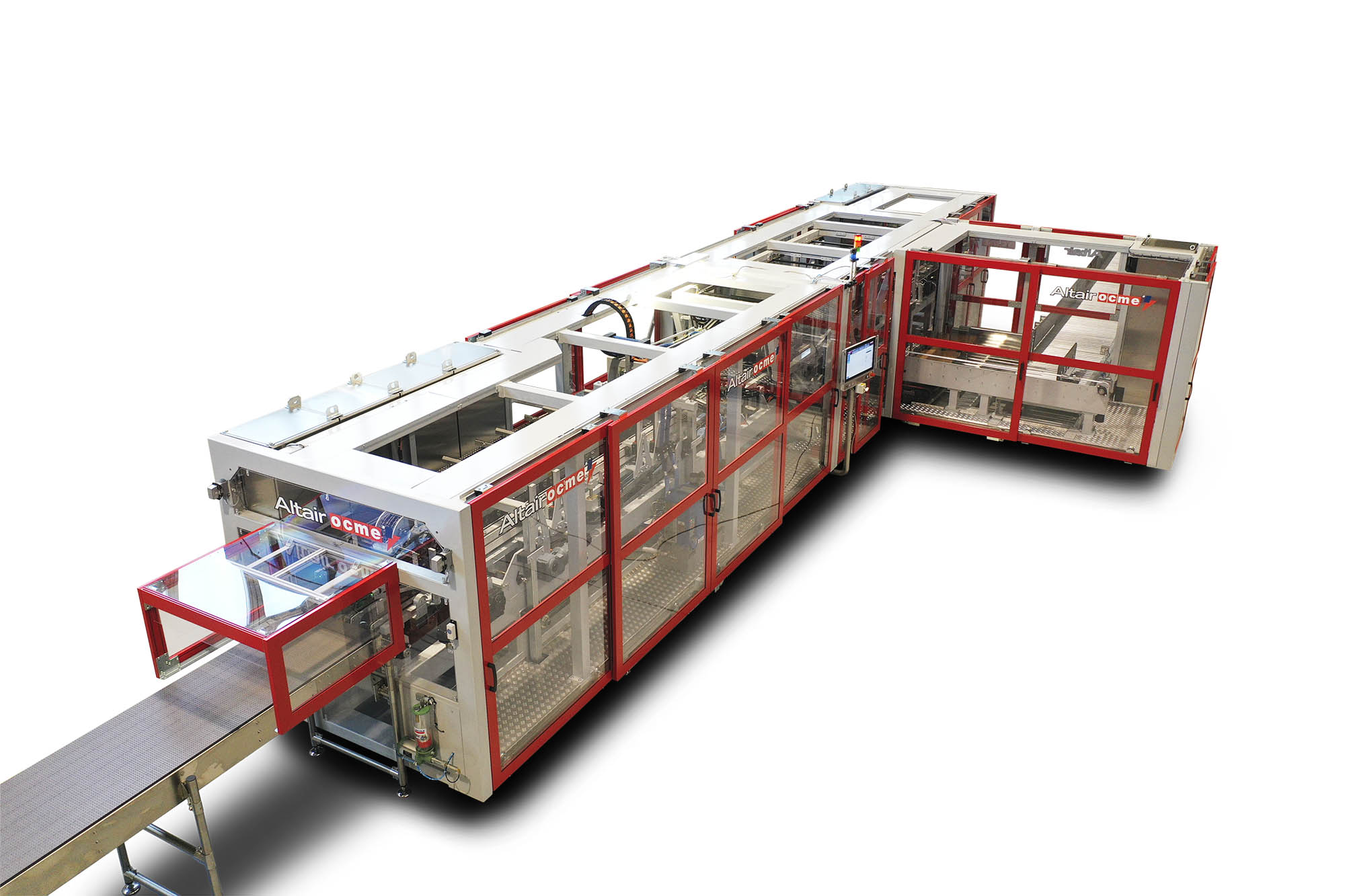

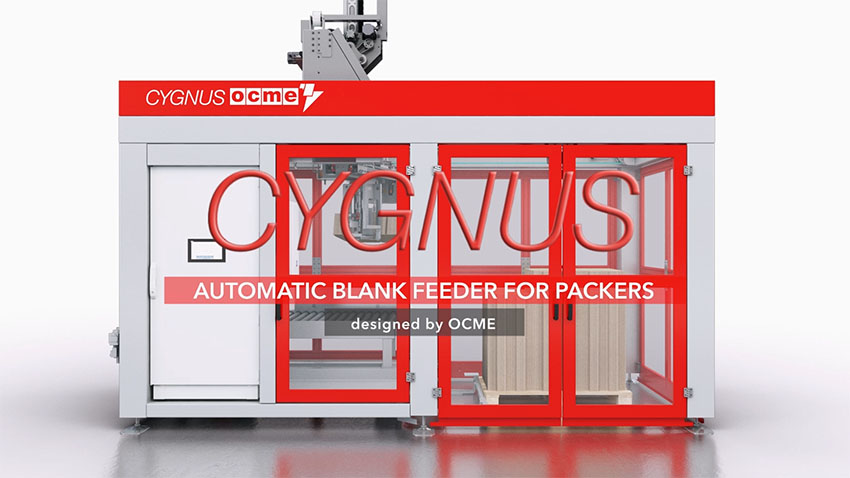

G.F: Two are the latest products: Altair and Cygnus – Automatic Blank Feeding.

Altair is a carton packer which wraps a flat carton blank around the products, and seals the pack with hotmelt glue. Thanks to this system, a single machine can reach a production speed of 100 cartons per minute, world’s fastest wrap-around cartoning machine.

OCME wrap-around carton packers are able to package many types of containers (plastic, glass, round, square, oval, triangular, etc.) and focus on high efficiency and high productivity installations, destined to various product sectors such as edible oil, lube oil and beverage.

Regarding Cygnus – Automatic Blank Feeding, the capacity of the blank magazine can be fed with a robotic blank picking system that move blank into magazine directly from the pallet. The pallet with blanks only needs to be positioned on the conveyor by the fork-lift truck driver who removes the wrapping strap, after which the machine runs completely automatically for a long time. The operator is thus relieved of the need to lift stacks of blanks manually.

E.E: What are the ranges of products?

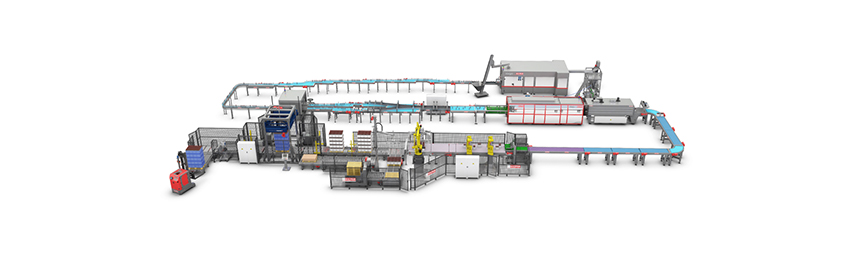

G.F: Our solutions are various and available to be “tailor-made”, accordingly on different request from each sector. OCME manufactures high quality packaging machines with different performance and configuration. OCME is not a simple supplier but the trusted partner for the end-of line solution, including fillers only for viscous liquid, a wide range of secondary packaging solutions, palletizing and internal logistic machines for any market.

E.E: At what stage is the market where you are currently active?

G.F: The Company creates high-performance solutions tailor-made to market and customer needs, with an extreme focus on circular economy issues. These are the main characteristics of a company of the latest generation such as OCME, dedicated in its DNA to the dynamics of Industry and Company 4.0, where digitalization and process automation become key elements to address the needs of the packaging world in an increasingly green-oriented key.

E.E: What can you tell us about market trends?

G.F: Aetna Group, with its Robopac and OCME brands on top, is a global reality, capable of bringing Made in Italy technological excellence to the world. We look to 2023 as the year of efficiency and productivity improvement and we aim for a future with a 360° sustainable growth perspective, creating a balance between economic, social and environmental levers.

E.E: What are the most innovative products marketed?

G.F: OCME, together with Robopac, is the main brand of the Aetna Group which offers a wide range of solutions and services for the end-of-line packaging industry: from semi-automatic wrapping machines, to automatic machines, shrink wrappers and case packers. A versatile and diversified offer that creates significant added value thanks to the synergic work of the individual business units.

E.E: What estimations do you have for the rest of 2022?

G.F: 2022 was certainly a complex year, but one that will nevertheless be remembered as the year of restart. After the upheaval imposed by the pandemic, we returned to the presence at the most important international trade fairs, to the warmth of human relations with our global community and to the value of interpersonal relationships, which are also fundamental in industrial development. The year has certainly rewarded us by recognizing us as a strong, organized and present reality, a global reality capable of bringing the technological excellence of Made in Italy to the entire world: the recent Drinktec made this even more evident, noting how Aetna Group, with Robopac and OCME, was the only major market leader capable of bringing plants running at real speed.

In the next future we will continue to invest: in Research & Development, to grasp and anticipate our customers’ needs; in training, which is essential for the growth of human resources; in acquisitions, such as the recent German company Meypack (in June 2022), to further strengthen our mission of internationalization.