OCTUM is a system integrator in the field of machine vision, whereas they develop tailor-made solutions for and with their customers. OCTUM is pushing the focus towards the pharmaceutical market and market for medical devices. OCTUM connects its expertise in machine vision with the experience in the highly regulated industry.

Easy Engineering: What are the main areas of activity of the company?

OCTUM: OCTUM follows two technical approaches to find the best solution for our customers. On the one hand we are using smart camera systems to perform inspection tasks in ultra-fast production environment like 600 parts per minute. The challenge of the systems lies in the simplicity of the software sequence in order to keep the time response low. On the other hand, we are working with a PC-based machine vision solution, whereas highly complex algorithms are used to realize difficult measurement tasks. OCTUM developed two software packages for both approaches to fulfil the regulations of the pharma and medical device market.

E.E: What’s the news about new products?

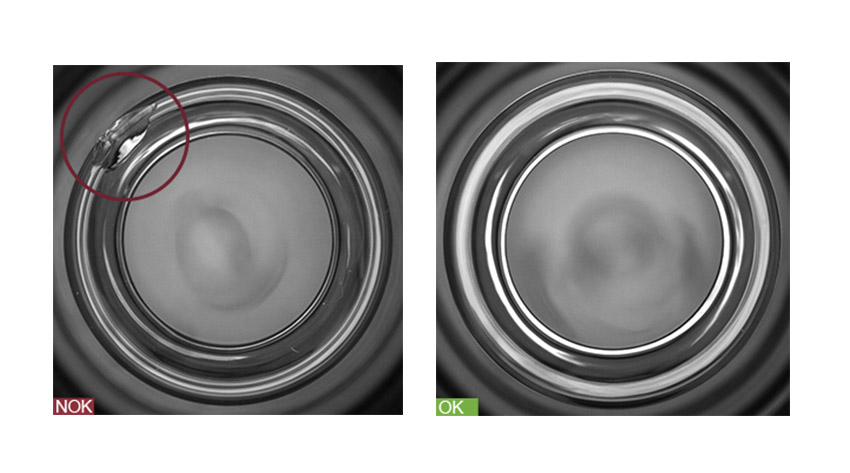

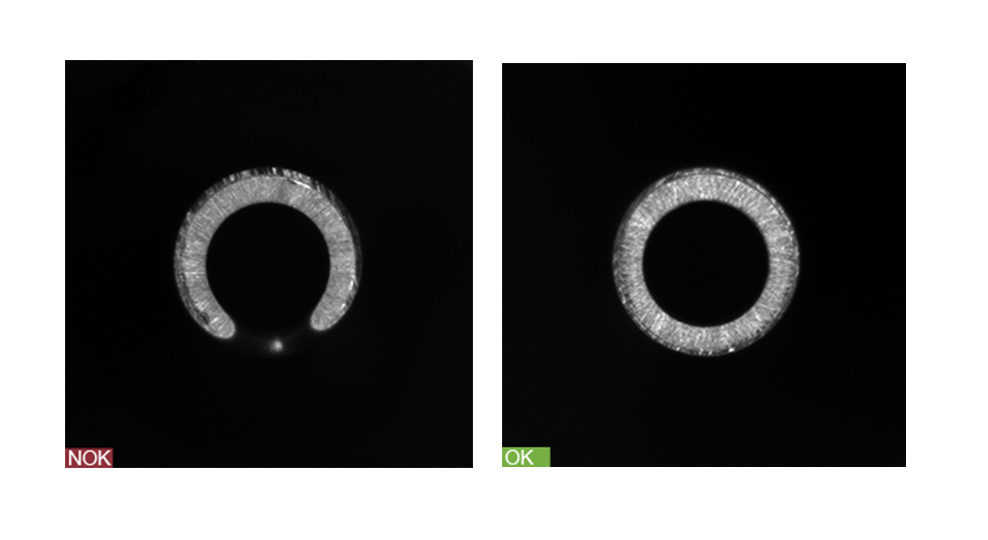

OCTUM: OCTUM delivers in the first stage tailor-made solutions for our customers. If a solution is well accepted on the market and upcoming requirements vary in a small range, OCTUM transfer the customized solution into a standardized system. In the end, we can supply the market in much shorter period of time and increase the quality of our machine vision systems for all of our customers. Therefore, we developed several standard systems ranging from the in-vitro diagnostics with our pipette.inspect going to different stages inside the vial filling lines from particle and material inspection to stopper seat and crimping inspection, calling vial.inspect, which will be labeled at last stage and can be checked with label.inspect. Following this idea, we create a broad and variable setup of inspection systems grouped in our syringe.inspect, which can be implemented into the different stages of the syringe production. After all, the patch.inspectsolution guarantees the quality of different patch shapes applied to the patient. In the early stages, we take care of the particular regulations to all of our applications and for instance implemented an audit trail and an active directory connection in our software packages.

E.E: What are the ranges of products?

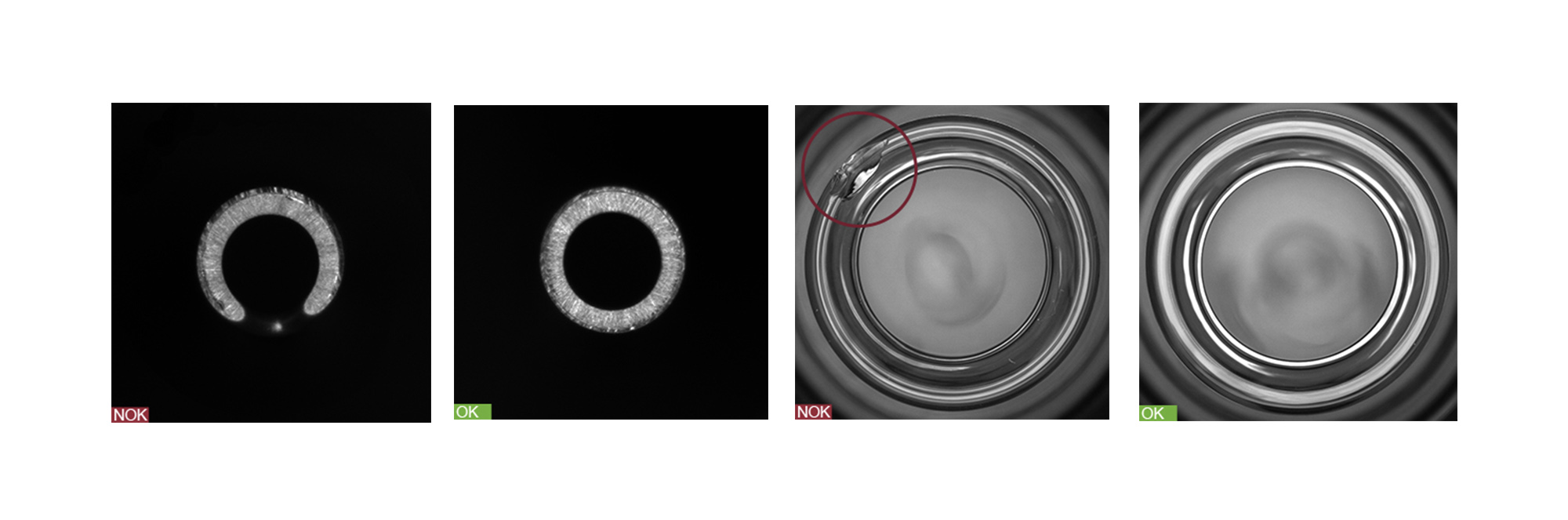

OCTUM: The focus of our solution lies on automated inspection systems to realize a 100% quality assurance in regulated industries. Within this scope, OCTUM wants to develop the best solution for the customers using classical two-dimensional machine vision concepts. Following the demand to find the best solutions, OCTUM tests constantly other machine vision approaches like laser triangulation or structured light scanner against the customer requirements.

E.E: At what stage is the market where you are currently active?

OCTUM: In the near past, the manufacturers became more aware of the machine vision systems build into their production lines due stronger regulations of computerized systems. As a consequence, the regulations became more and more challenging. The amount of time needed for the qualification of the systems onside of the machine builder is equal or sometimes larger than implementation into production line itself. Based on this circumstance we are continuously optimizing our life time documents. Therefore, a small team was established two years ago, who prepare the customized documents and monitor the development of the guidelines in the regulated markets.

E.E: What can you tell us about market trends?

OCTUM: Looking into the future, the deep learning approach will be present in the quality assurance inside the production process. This approach allows the machine vision community to perform highly challenging tasks like surface inspection on varying background or reading of characters on structured surfaces. I want to point out that the deep learning tools can be seen such as regular tools inside the machine vison tool set like the edge detection or the OCR. Following this, the parameterized or trained neuronal network acts deterministic on the same input data. Hence, the entire system can be validated and used inside highly regulated market like the pharmaceuticals and medical devices.

E.E: What are the most innovative products marketed?

OCTUM: Recently, we developed on our own invest a new approach to inspect pipette tips within a multi camera setup. The innovations are the fast-processing time and the 100% inspection of pipette tips regarding the eccentricity. State of the art is a measurement of random sample, whereas the pipette tip needs to be rotated to allow different views to the object. Based on this, a complex algorithm is used to calculate the eccentricity. We extended this setup by a second camera and simplify the post-processing to enhanced the total processing time. Beside the technical solution, all of our systems generate a huge amount of data. We give the manufacturers access to this huge data set by using the visualization for our SQL database. In sum, the measured data become easily accessible and trends during the production are visible in early stages. Based on this, the production line can be readjusted and the rejection rate decreases.

E.E: What estimations do you have for 2022?

OCTUM: The corona pandemic impeded the exhibitions irrespective of the industrial sector in the last two years. I am positive about new innovations, which have been developed behind scenes. Hence, I am expecting a broad spectrum of new product releases in the upcoming road shows and trade fairs. From OCTUM’s side, we used the early past to develop a new software product for machine vision systems allowing to implement the deep learning approach for beginners as well as for experts. I am confident that we will show first insights at the end of this year.