Optimax provides visual inspection and metrology solutions, focusing on driving efficiency & productivity for clients. Their aim is simple – to ensure inspection and measurement is accurate, reliable, and repeatable, on time, every time.

Interview with Clare Belton, Head of Marketing at Optimax.

Easy Engineering:What are the main areas of activity of the company?

Clare Belton: Specialists, in providing products and services for controlling product quality, typically in the precision manufacturing environment. Dimensional measurement, through tactile and optical methods, is complimented by surface characterization, roughness and force.

We are an automation specialist for the deployment of inspection equipment, releasing precious resource to concentrate elsewhere in the business.

Solution-based, technical advice across industries including aerospace, automotive, precision engineering, medical devices, packaging, and cutting tools.

Complimenting key product offerings, is our fully accredited ISO17025 UKAS calibration laboratory. Service, repairs and training packages also support our valued customers.

E.E: What’s the news about new products?

C.B: It’s all about automation!

With an estimated shortfall of 85 million workers world-wide and an ever-increasing pressure on the bottom line means the demand for automation in visual inspection and metrology has hit an all-time high. Here at Optimax we have seen an increase in interest in our automation portfolio as customers are looking to streamline their processes.

Effective automation in metrology and visual inspection can reduce costs due to the decreased need for a highly skilled workforce and the up-shift in machine autonomy. Machines can run 24/7 with limited human intervention. Saving costs and increasing productivity.

E.E: What are the ranges of products?

C.B: In tactile metrology, the Optivu Dextera system has seen an increase in interest. The Dextera consists of a Deltron CMM and the latest Cobot (Collaborative Robot). By combining these technologies, you can automate your tactile metrology even in uncontrolled environments. The system offers large capacity on a small footprint, which once integrated into your production will give you accurate, repeatable, fully automated, fast tactile metrology.

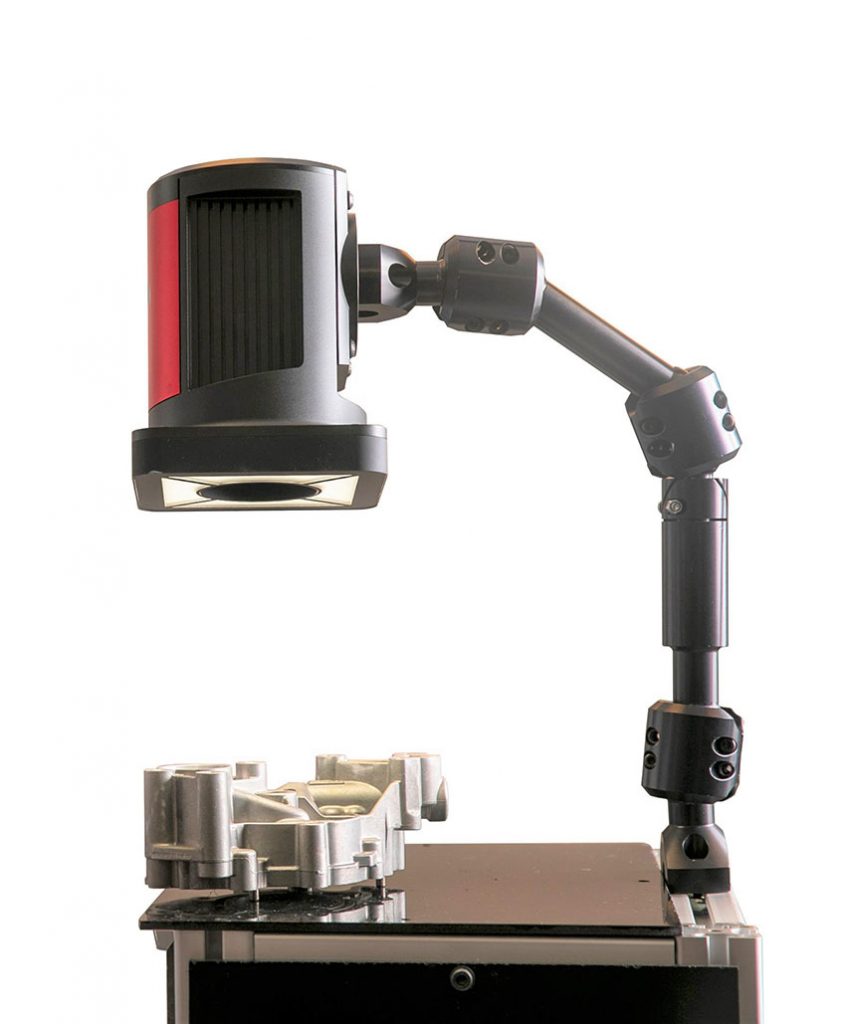

We have also seen demand grow for AI-guided inspection. Optivu Inspekto provides AI -driven visual quality & production inspection, which is easy to use (plug and play!) and integrates into most production systems. The AI capabilities recognize the characteristics of a good part or bad part. This system is revolutionary and low-cost.

Pick and place automation is playing an increasing part in visual inspection and metrology workflows within industry. Integrated Robot’s and Cobot’s can now demonstrate improvements in efficiency and ROI.

E.E: At what stage is the market where you are currently active?

C.B: The issues around global supply chain has meant that here at Optimax we have seen a demand in requests for integrated solutions. Customers are looking to improve workflows and efficiency, whilst still maintaining high standards of accuracy and precision that visual inspection and metrology demands for their applications.

E.E: What can you tell us about market trends?

C.B: Innovative technologies such as automation and AI have seen significant growth and this is projected to continue for 2022 – 2027. Sustainability is also set to be a key factor in buying behavior in the metrology sector.

E.E: What estimations do you have for the rest of 2022?

C.B: Optimax predicts that we will continue to see growth and innovation in the metrology sector as the demand for AI & automation accelerates. We will look to continue to showcase our product portfolio via trade exhibitions, through our website and virtual demonstrations.