PAUL MASCHINENFABRIK is a medium-sized family business from Southern Germany, which is internationally active and manufactures and sells machines and equipment for industrial woodworking and prestressed concrete technology.

Easy Engineering: What are the main areas of activity of the company?

PAUL MASCHINENFABRIK: On the one hand, we manufacture circular sawing machines for sawmills, flooring manufacturers, furniture manufacturers, window manufacturers and many other woodworking companies. In addition to circular sawing machines, our scope of supply also includes state-of-the-art scanners for automatic detection of wood defects but also automation solutions.

On the other hand, we manufacture machines for the production of prestressed concrete.

E.E: What’s the news about new products?

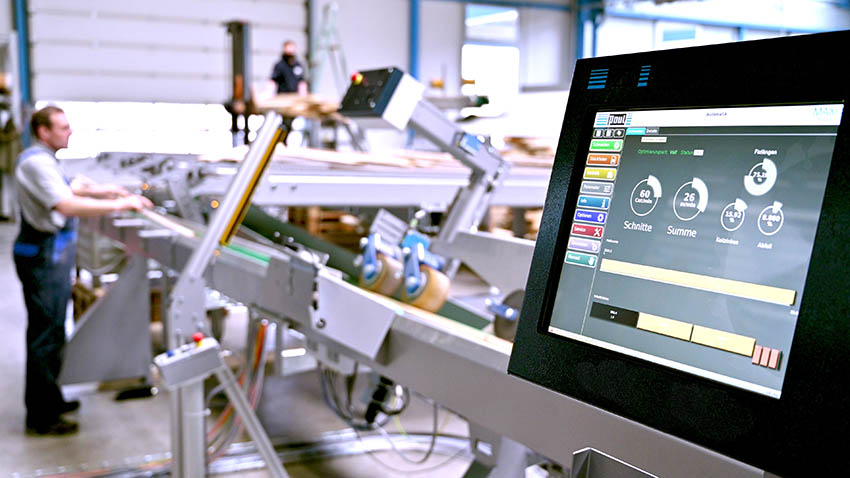

PAUL MASCHINENFABRIK: One of the latest developments is our fully automatic scanner for the detection of defects in solid wood workpieces, which can also be used for longitudinal sawing. Scanners are no longer a novelty in woodworking. When boards are sawn to length, scanners have been used for many years.

However, when board material is sawn lengthwise into strips, scanners have usually been very expensive. However, we have developed a system that pays for itself after a short time and significantly increases the wood yield.

E.E: What are the ranges of products?

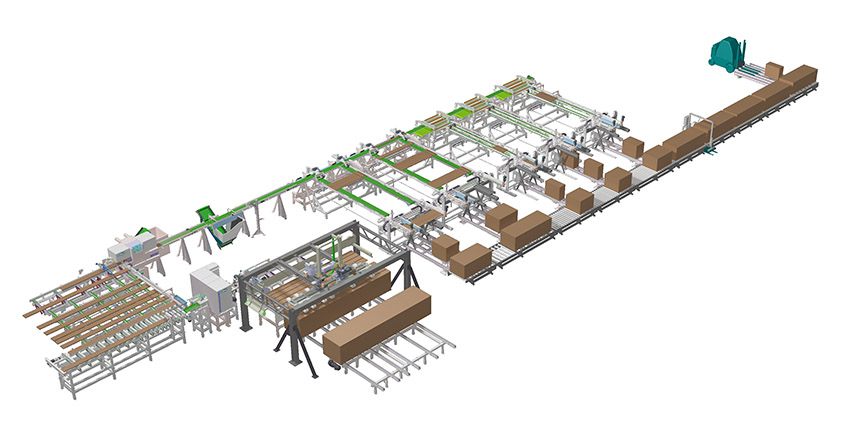

PAUL MASCHINENFABRIK: We supply both small stand-alone machines, which are operated manually, up to complete and fully automatic production lines for very large outputs. Our customers include companies with one employee as well as large international corporations.

Our products include cross-cut saws, CNC controlled cross-cut systems, double edging circular sawsre saws, panel saws, automatic feeding systems, stacking systems, conveyor systems and scanners.

In the prestressed concrete division, we supply prestressing jacks, strand jacks, clamping wedges and many other accessories.

E.E: At what stage is the market where you are currently active?

PAUL MASCHINENFABRIK: Our markets are already very well developed and strongly occupied. They are traditional industries with a long history. It is becoming increasingly difficult for our customers to find qualified employees. Therefore, the trend is clearly moving towards more and more automation.

Of course, the issue of sustainability also plays a major role, which is why wood yield is also gaining in importance.

E.E: What can you tell us about market trends?

PAUL MASCHINENFABRIK: The topics of the future are certainly automation solutions, digitalization, sustainability and energy efficiency.

E.E: What are the most innovative products marketed?

PAUL MASCHINENFABRIK: In our industry, fully automatic image processing (scanner technology) and the use of automatic robots is certainly a major trend that will become increasingly important in the coming years. In scanner technology, the trend is toward artificial intelligence and learning systems.

E.E: What estimations do you have for 2022?

PAUL MASCHINENFABRIK: Despite Corona, we had a very strong year in 2021 and expect the markets to calm down somewhat next year. Nevertheless, we believe that 2022 will also be a good year.