PCB Arts is an engineering office from the heart of Germany in the field of electronics development. The team consists of hardware & software development enthusiasts who are dedicated to excite customers with high quality solutions.

As a young company, continuous improvement through innovation is one of their driving values. On the way as a development service provider, PCB Arts has created products from their own needs with the intent to improve the lives of other engineers.

In addition to engineering services, their portfolio now also includes a vapor phase soldering system “Vapor Phase One” and an Edge-AI system “EdgeKit”.

Easy Engineering: What are the main areas of activity of the company?

PCB Arts: As stated, our two main pillars are engineering services and the Vapor Phase One, our self-developed, open-source, vapor phase soldering oven.

Due to the cooperation in numerous international projects, we look back on an exciting project history.

Our portfolio includes not only digital but also analog circuit development. Generally, we develop your PCBs in Altium or Circuit Studio. After we have developed a prototype and it arrives at our facility, it is tested for functionality and verified in our Pre-Compliance EMC lab. This reduces ‘time to market’ and certification costs to a minimum.

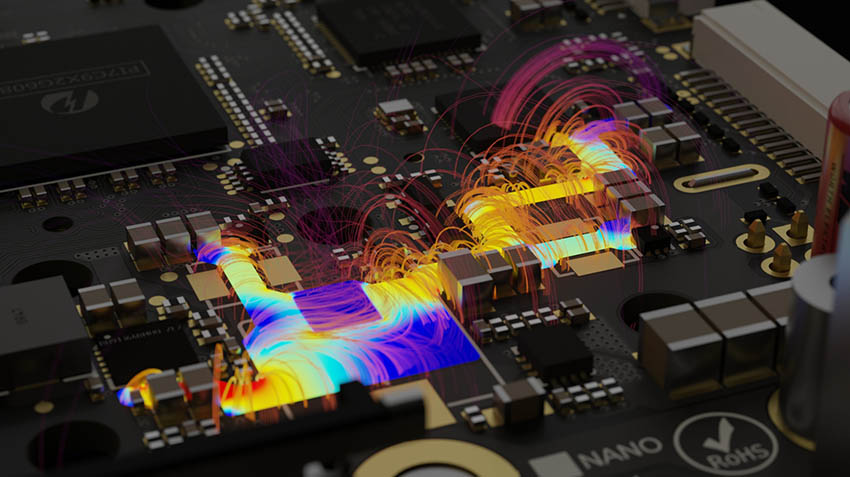

To ensure function, operational reliability and compliance with the specification under numerous environmental influences, simulations are key. In addition to temperature simulations and tolerance analyses of components, this also includes the simulation of parasitic influences. In this way, potential problem areas can be identified and eliminated even before the first prototypes are produced. We simulate in LTSpice and Elmer.

E.E: What’s the news about new products?

PCB Arts: From a product perspective, the release of the Vapor Phase One is a milestone in our history for sure. As an engineering office, we experienced firsthand the advantage of vapor phase soldering and unfortunately the lack of affordable tabletop devices that fulfill our requirements.

So, long story short, we created our own product and are happy to support engineers all around the world. This was an exciting journey for us, going all the way from the idea over a crowdfunding campaign to certifying the VPO for international markets.

E.E: What are the ranges of products?

PCB Arts: The Vapor Phase One offers development engineers as well as small to medium sized prototyping service providers one of the gentlest soldering processes in the industry. In contrast to infrared or convection processes, assemblies with high thermal mass, fine pitch structures or temperature-sensitive components can be processed without any problems.

Here is how it works: Vapor phase soldering – also called condensation soldering – is based on similar physical principles to a heat pipe. An inert liquid is brought above its boiling point, causing a vapor phase to form just above the surface. This liquid is a specially developed medium called Galden® that boils between 230 °C and 240 °C, depending on the type. This newly formed vapor transports energy from the heat source to one or more “heat sinks”. In this case, these heat sinks are your PCB, your components and the applied solder paste. The vapor condenses on the cooler surfaces first, so it transports a greater amount of energy to those areas and gently heats your board. The solder paste melts as soon as your PCB reaches the appropriate temperature. Also, the maximum temperature it can reach is limited by the boiling point of the Galden®.

E.E: At what stage is the market where you are currently active?

PCB Arts: As components become smaller and more complex, vapor phase soldering is becoming increasingly important. Furthermore, we experience from customers that the product life cycles and thus also the development cycles in the electronics industry are getting shorter. This requires more prototyping, for which Vapor Phase Soldering is perfectly suited. Especially due to the increased complexity, defect-free soldering is becoming more and more important.

E.E: What estimations do you have for the rest of 2022?

PCB Arts: We are pleased to experience that more and more customers in Europe and the USA are realizing their projects with the help of our products. Through cooperation with regional distributors, the Vapor Phase One is accessible to everyone. With the help of customer feedback, we are always working to improve our products and are looking forward to exciting projects to come!