PennPac is a leading flexible packaging film supplier, servicing customers in a number of industries – from food & beverage to consumer healthcare. PennPac services both US and Canadian markets, focusing on quality and reliability.

While most film manufacturers and extruders are strategically aligned to produce large quantities of packaging film(s), converters and end-users prefer to manage just-in-time inventory or spot buys. By offering a “service oriented” business model with slitting assets and warehouse capacity, PennPac provides customers with timely service and sourcing flexibility. As marketing initiatives and product specifications evolve, PennPac is capable to adapt with short notice.

In 2021, PennPac expanded its operations with a new state-of-the-art facility in Piedmont, South Carolina. This strategic location is the first phase in executing their aggressive brand awareness, delivery time, and cost reduction initiatives. With additional capacity, the company is able to provide customers with competitive pricing and the ultimate program flexibility.

PennPac’s continued growth stems from the continuous re-investment in people and equipment, coupled with customer-centric business philosophy. For over 20 years, PennPac has focused on team building and employee retention allowing the company to excel and maintain their commitment to safety, quality, and efficiency.

Easy Engineering: What are the main areas of activity of the company?

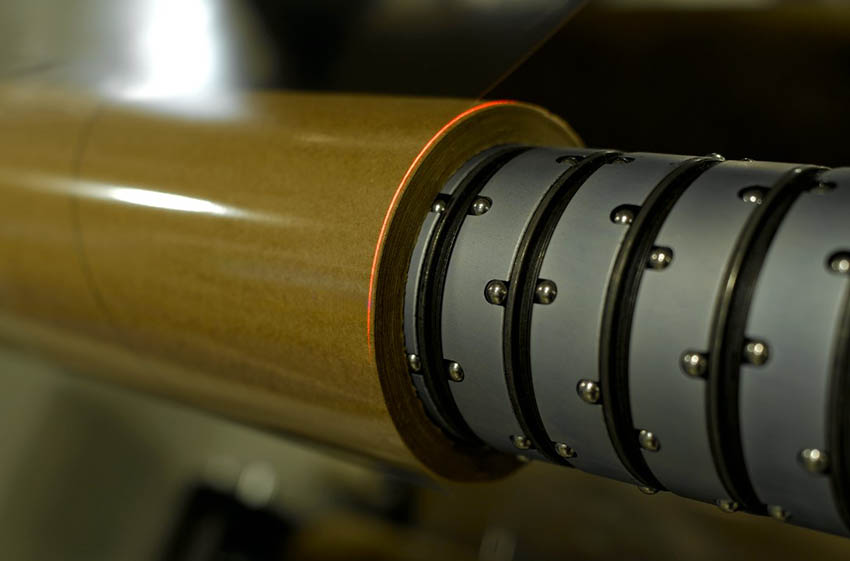

PennPac: PennPac’s core competency is slitting, rewinding, and warehousing raw flexible packaging materials. Within our facilities, PennPac utilizes 14 various slitters to reduce the web width and diameter of mill rolls. Most mill rolls are over 7 feet wide and have over 10 miles of film on them, weighing in at close to a ton!

Additionally, PennPac offers contract/toll slitting programs to customers that do not have the time, facility space, nor the resources to handle secondary slitting operations. Printers and laminators send us their WIP (work in process) to convert to finished goods, warehouse, and seamlessly ship directly to their customers. All of our assets are capable of handling both printed and unprinted film(s)

E.E: What’s the news about new products?

PennPac: PennPac is proud to announce our new product line consisting of High Barrier (HB) packaging films. HB films offer a maximum level of barrier protection when compared to other mono-layer films. At PennPac, we offer HB films containing Ethylene Vinyl Alcohol copolymer, commonly called EVOH. The film is a 9-layer structure utilizing the EVOH for barrier properties and nylon, polypropylene (PP), and polyethylene (PE) for strength.

The flexibility that EVOH provides makes it a popular barrier material for many different food applications, as well as non-food applications such as cosmetics and pharmaceuticals. This material can most commonly be seen in your local grocery store’s meat/poultry/fish coolers. It often has a colored, printed back and a crystal clear flexible front to show freshness of your favorite cuts of meat and fish!

E.E: What are the ranges of products?

PennPac: Our range of products continue to be of the nation’s leading custom sized flexible packaging options, focused around Biaxially Oriented Polypropylene (BOPP). In addition to our flagship line of BOPP, we also offer Metalized OPP, PET, White Label films, Cast OPP, along with many other specialty films. All film offerings are available on either 3” end-user cores, or 6” converter cores.

PennPac has a number of processes in place to support quality and food safety management systems to ensure we meet or exceed industry standards and FDA regulations. All of our internal procedures ensure that customers not only get fast order delivery, but also receives a quality product, every time.

E.E: What can you tell us about market trends?

PennPac: Market trends tend to vary based on marketing and sales activities within our industry. Typically, raw material cost, availability, and packaging design push market trends in many directions. For example, seasonality drives marketing and design trends based on geographic location. Thus, a package or film structure may vary with climate. As such, PennPac is able to work closely with our customers to provide timely solutions to their ever-changing flexible packaging needs.

E.E: What estimations do you have for 2023?

PennPac: As PennPac approaches the end of Q1, we estimate that consumer demand, technological advances, and supply chain diversification will continue to prove the packaging market a very intense and competitive landscape. We are confident with our position in the industry and look forward to an exciting 2023 providing reliable flexible packaging solutions!