Piva Group was set up in 1986 to manufacture insulation panels, doors and windows made of various combinations of materials, aluminium and PVC for the building trade. Piva Headquarter is located in Roncanova di Gazzo Veronese, in the Province of Verona (Italy) and in the same area are dislocated 5 more operational centers.

The production departments and the offices occupy a total area of about 120,000 sqm, where more than 800 people work with passion and scrupulous dedication, paying particular attention to functionality, aesthetics and details of the windows created.

The search for new techniques to develop innovative products has made the Piva brand well-known not only in Italy but also in international markets, consolidating its international dimension with the opening of subsidiaries in Spain, the USA and the Czech Republic.

Today Piva is a prestigious name in the building trade thanks to its production versatility, its product quality and its corroborated experience.

A Company always ready to match its customers’ needs, where Future is the watchword.

Interview with Dr. Alessandro Piva, C.E.O. Piva Group S.p.A.

Easy Engineering: What are the main areas of activity of the company? / What are the ranges of products?

Alessandro Piva: Piva Group is composed by 3 main Departments:

Mondial Infissi

Manufacturing of windows and doors in aluminium and PVC for modular construction (modular housing units, insulated mono-blocks, prefabricated boxes).

Pannelli System

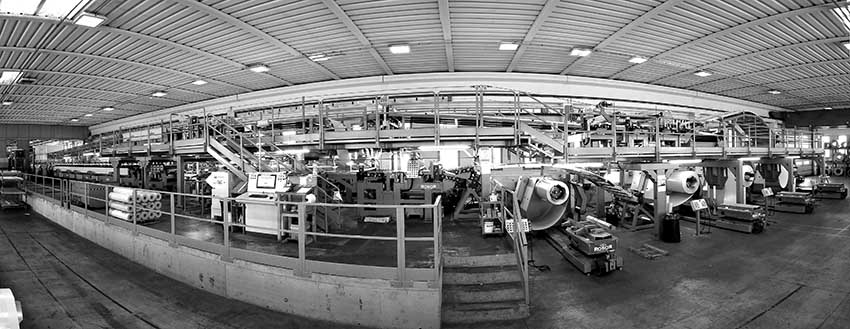

European leader in the manufacturing of insulated sandwich panels for walls and roofs, both in continuous and discontinuous production line. In continuous production we manufacture polyurethane panels; in discontinuous production we manufacture sandwich panels in polyurethane, polystyrene and mineral wool.

Residential Division

We design and manufacture PVC windows and doors of different geometries. Our solutions, ranging from classic to modern, are made with care and precision thanks to innovative accessories and high-quality raw materials.

E.E: What’s the news about new products?

A.P: On the one hand, we can say that we don’t have a proper new product because the peculiarity of our Company is to create products based on our customers’ needs (the so-called tailor-made process). All the products that our Technical Department is developing are not exclusively Piva Group products, but products that Piva modifies and updates according to the requests of our customers.

On the other hand, we are working to expand our line of Thermal Break Aluminum doors and windows, introducing increasingly high-range products, both on the residential/civil market and in the modular sector.

E.E: At what stage is the market where you are currently active?

A.P: Piva Group is active in a Market that enjoyed an impressive euphoria in the first part of the year, even though the price of the raw materials was incredibly high. To date, these prices are still high because they are led by the cost of gas and energy, especially in energy-intensive departments such as glass, painting and profile extrusion.

However, even though the Market has lost its initial euphoria, we can say it’s still a good Market and Piva Group will close well in 2022 – last year, the three business areas where we are operating in Italy (PVC, Aluminum and Panels) recorded an aggregate turnover of over 130 million euros, while for the current year the projection is to reach 160 million.

Nevertheless, for the year 2023 the forecasts are less optimistic, due to the trend in costs for energy and raw materials; although the cost of raw materials is falling, the increase in energy costs will not allow us to replicate the business volume we had in 2022.

E.E: What are the most innovative products marketed?

A.P: We are focusing on some products that occupy a market niche, namely the tourism, hospitality and camping sectors. We are studying customized solutions for our clients, in a very specific sector that we have never investigated. This is a market that requires production close to the places where the final products are then delivered and assembled, to ensure constant service and post-sales assistance, which is why we have activated a few production sites in various areas of Europe.