Plastics Recyclers Europe (PRE) represents the voice of the European plastics recyclers who reprocess plastic waste into high-quality material destined to produce new articles. Recyclers are an essential part of the solution for the plastic waste crisis. They drive the circularity of plastics and the transition towards circular economy.

Plastics Recyclers Europe has been working relentlessly to put plastics recycling in the spotlight of the public debate. For over 25 years, it has promoted recyclates use and high-quality recycling across Europe, and beyond.

The company’s mission & vision is making plastics fully circular by advancing highly efficient plastics recycling & producing high-quality recycled plastics in Europe by:

- Advancing circularity of plastics through increased quality plastics recycling & use of recycled materials in high-end products;

- Improving recyclability of plastic products;

- Harmonising the recycling standards & practices across Europe;

- Supporting a genuine transition towards circular economy.

Interview with Emilia Tarlowska, Public Affairs and Communications Manager at Plastics Recyclers Europe.

Easy Engineering: What are the main areas of activity of the company?

Emilia Tarlowska: With over 25 years of experience, PRE is a well-established body within the EU political arena representing European plastic recycling companies. Our organization has put plastics recycling at the center of the public debate.

Via working on various projects PRE looks for solutions which can help advance the recycling and promote the best practices while ultimately seeking to increase quality collection, sorting, recycling and recyclates uptake in Europe.

The organization produces market studies and reports covering a wide range of topics including production, trade, collection, reprocessing and recycling of the main plastic waste streams in Europe.

We collaborate with the actors from across the value chain to harmonize and improve circularity of plastics with the long-term objective in mind. This includes businesses, policymakers, academia, and different institutions in Europe and beyond. We work with organizations including: The Association Of Plastics Recyclers (Apr), New Plastics Economy’s Global Commitment, Circular Plastics Alliance European Plastic Pact, Un Treaty On Plastic Pollution and many others.

Emilia Tarlowska, Public Affairs and Communications Manager at Plastics Recyclers Europe.

FLAGHSIP INITATIVE OF PRE– to drive recyclability and recycled content uptake: RECYCLASS

Non-profit, comprehensive cross-industry initiative that works to advance plastic packaging recyclability and to establish a harmonized approach towards recycled plastic calculation and traceability in Europe. Activities within RecyClass include the development of Recyclability Evaluation Protocols and scientific testing of innovative materials which serve as the base for the Design for Recycling guidelines and the free Online Tool. RecyClass offers Recycling Process Certifications, Recyclability Certifications for plastic packaging and Recycled Plastics Traceability Certification for plastic products. Certification of recycled content is based on the chain of custody model ISO 22095, EN 15343.

Flagship event of PRE:

Our organization is co-organizing the Plastic Recycling Show Europe – the focal event of the plastic recycling industry as well as the Plastic Recycling Awards Europe.

E.E: At what stage is the market where you are currently active?

E.T: We represent recycling companies who treat plastic waste coming from households, retailers, and industry.

E.E: What can you tell us about market trends?

E.T: Plastics recycling in Europe established itself, over the past decades, as one of the important tools in solving the plastic waste crisis. Being one of the best alternative feedstocks to virgin plastics it reduces Europe’s dependency on natural resources while decreasing CO2 emissions by up to 90% when compared to the primary material.

Recycling emerged back in the 1980s with in-house, post-industrial waste recycling and soon expanded into reprocessing post-consumer waste. A good example here is the recycling of flexible plastics (LDPE), where in the past only commercial waste was recycled, and the recyclates used back into the niche and rather low-end applications whose life-cycle would end after being recycled only once.

Today post-consumer recycling is already an established practice with high-qualities available and high-end applications which means that, for example, flexible packaging coming directly from your home is now turned back to the same or similar products and can be recycled many times over. Recycled flexible packaging is used also in the construction sector to produce, for example, protective and waterproofing membranes.

Another example is Polyethylene terephthalate (PET). It is one of the most widely used recycled plastic and at the same time the most widely recycled polymer to be destined for food contact applications. Just a few years back recycled beverage bottles (PET) were used mostly to produce fibers (for strapping or clothing, for example), today their biggest outlet is packaging. It is used, for example, back in the same, high-value products as bottles and trays (including food contact applications) – which both can be used for food contact packaging.

With innovation and technological developments, we have achieved today high-quality recycling which enables us to produce high-end products with recycled plastics having almost the same properties and characteristics as the products with virgin plastics.

The figures show that over the past two decades plastics recycling has been steadily growing and just within 5 years it grew by more than 60%.

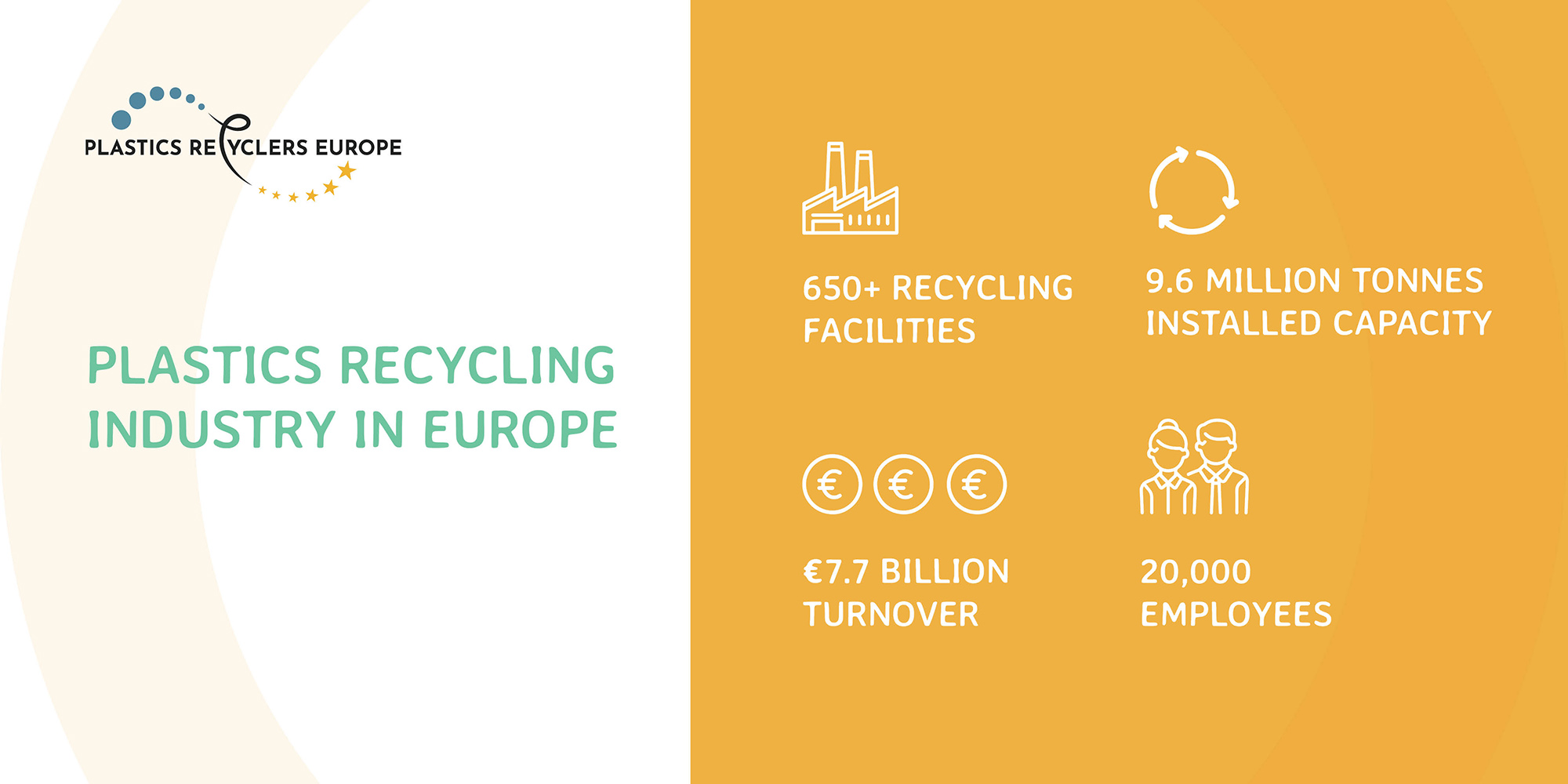

Back in 1996, the total installed recycling capacity was estimated, roughly, at 200.000 tones. Today it equals over 9.6 million tones.

Beverage bottles and trays (PET), flexible plastics (LDPE), and containers (HDPE) are the plastic waste streams with the highest collection and recycling rates in Europe.

Although there are some differences in systems, performance, and availability of infrastructure across the EU countries, there is a growing trend toward sharing and using best practices and new technologies to further increase the quality, efficiency and effectiveness of plastic recycling processes.

The future growth of the installed capacities will vary depending on the type of waste stream but, taking into considerations the EU recycling targets, these numbers are set to substantially expand thanks to the new policies, targets and economic incentives but also to thanks to the commitments of the value chain actors to increase plastiscs’ circularity.

For example, the polyethylene (PE) stream has one of the highest potentials to reach the EU recycling targets. In particular, flexible plastic recycling is projected to triple by 2030 if the additional collection and high quality sorting tonnages are unlocked and other bottlenecks are overcome. It means that it could substitute even 36% of the virgin demand.

Plastics recycling is part of the puzzle of solving the plastic waste crisis. Surely, it cannot play its role alone but rather must work hand in hand with solutions like prevention, reuse and design for recycling.

One thing is certain robust policy, technology and collaboration across the value chain will continue driving plastics recycling.