Since April 2021 INAS Engineering became a daughter company of PolyMerge. Both companies are focused on production equipment for complex polymer products. With their joint forces the company group grew to a supplier of entire production lines for production lines – from injection molding removal handling, over assembly automation, welding, testing equipment to packing and stacking automation.

Easy Engineering: What are the main areas of activity of the company?

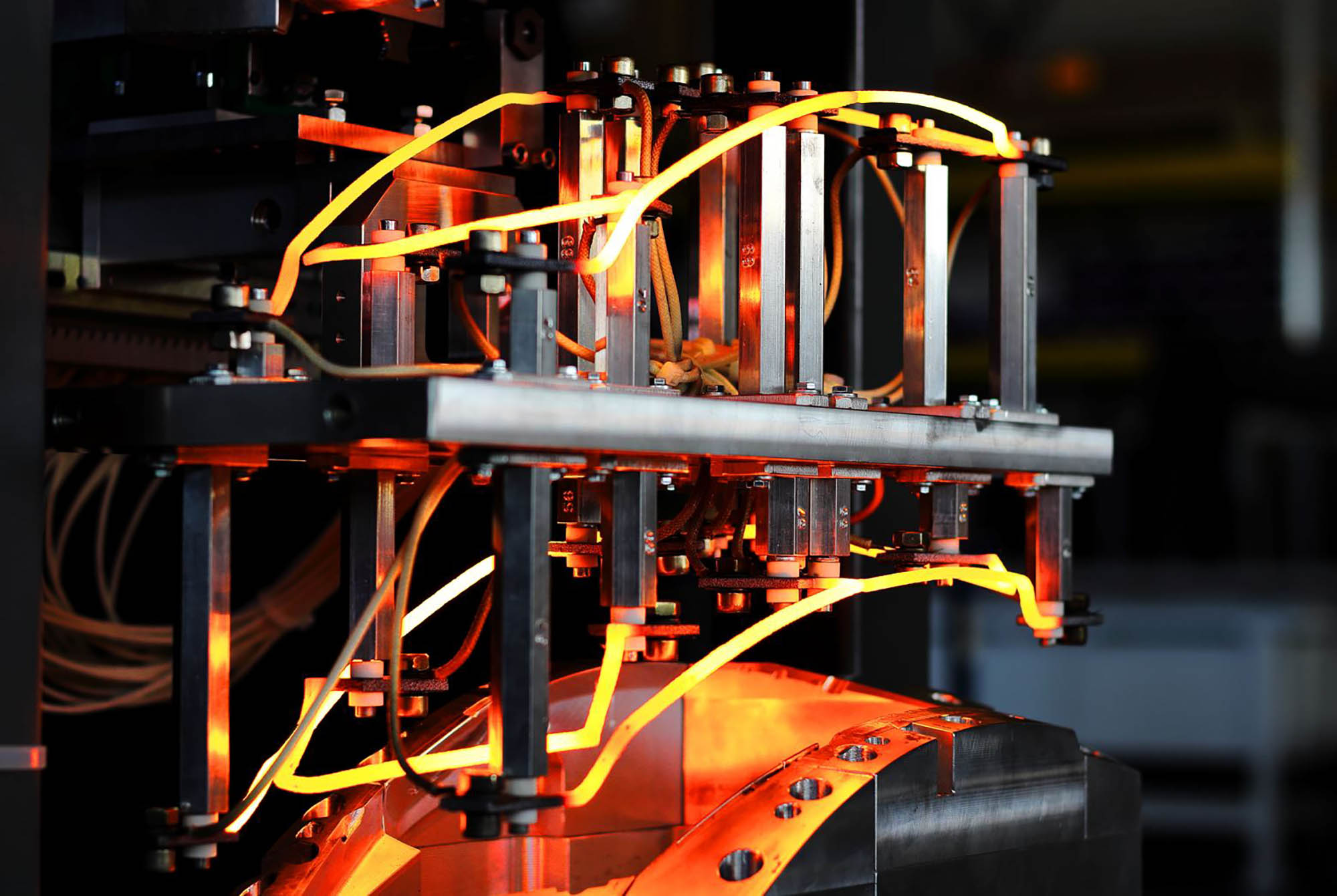

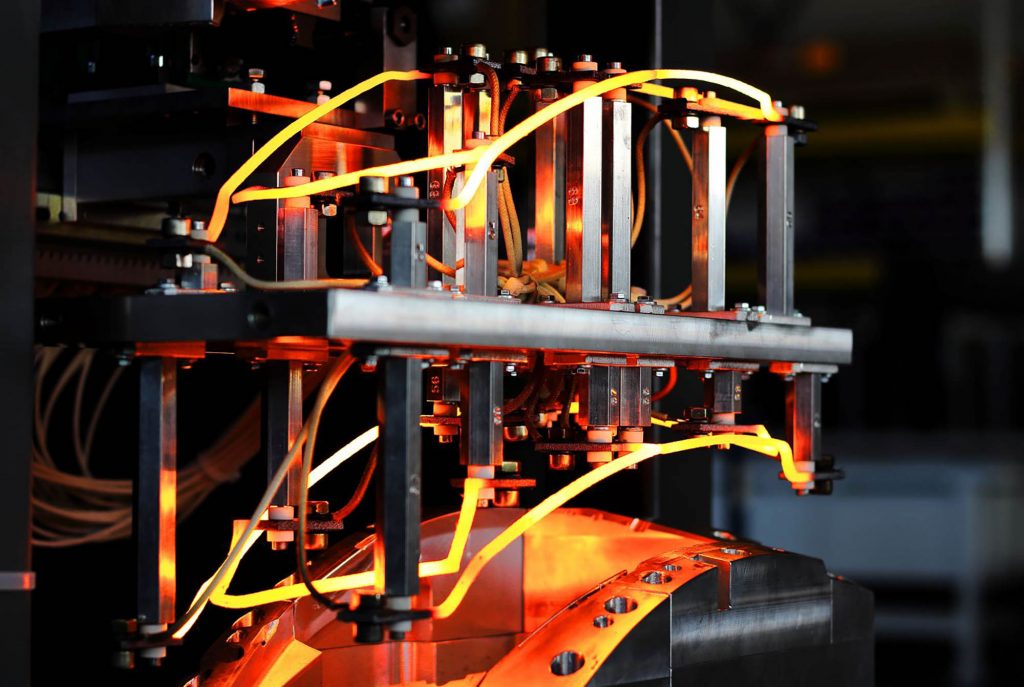

PolyMerge: The core focus of the company is assembly automation equipment and polymer welding. The variety of different welding processes offered is uniquely high. It starts with tailored machines for Ultrasonic Welding over hot plate-, Infrared- and laser welding.

E.E: What’s the news about new products?

PolyMerge: Over the past 2 years PolyMerge applied 3 new patents and developed the products based on this know how. One core patent is the brand-new Infrared welding approach which is based on a unique 3D printing process of ceramic materials. PolyMerge maintained to modify the ceramic substrate to enhance its electrical conductivity.

Unlike to the known processes, the printed emitters offer following advantages:

- Highest geometrical freedom

- High optical performance (by the factor of 16 compared to metal foil)

- High service life

The machines based on this technology are offered under the trade name of InfraMerge.

Another new product the CircleMerge System. The machine carries out a friction welding process with an oscillation of its top tool in a circular manner. The technology is intended as an compromise between ultrasonic and laser welding. The gentle movement allows joining electronic casings and reaches at the same time short cycle time in the region of ~2s. The Technology allows the use of sensors and actors in the top tool.

Further the company just started a cooperation with VAB Wegner in Minden. VAB Wegner owns IP in the field of hot gas welding which offers great advantages in processing of oxidation critical polymers e.g. PA6.6 by the uses of nitrogen as inert protection gas. With this technology PolyMerge is one of very few suppliers with solutions for processing of such high performance polymers.

E.E: What are the ranges of products?

PolyMerge: PolyMerge INAS mainly supplies the automotive industry with production equipment. Most machines go to TIER1 companies producing Fuel tanks, coolant and brake oil tanks, interior applications und exterior products. However, beside the automotive industry customers from the white goods and medical field are supplied.

E.E: What estimations do you have for 2022?

PolyMerge: With the new products and the new possibilities in terms of cost savings and new design, the year 2022 will develop positive for the company. Even much larger companies are active in the marked, PolyMerge INAS gains great attention as a fresh and very innovative full service provider in the field of production line planning, supply and consultancy.