POMDI is a second-generation company, funded with 100% of Spanish capital. Founded in 1972, “POMDI” – Herramientas de Diamante, S. A., is today one of the leading industrial diamond tool manufacturers. Right from the start, POMDI’s aim has always been to offer its clients a wide variety of super-abrasive industrial diamond and cubic boron nitride (CBN) machining solutions for the industrial sector.

POMDI’s mission is to offer cost-effective machining solutions to all current and potential super-abrasive machining users. Our goal is to become the leading point of reference for both our clients and our suppliers whilst creating value for our shareholders, employees and society.

Easy Engineering: What are the main areas of activity of the company?

POMDI: Due to its profound technical knowledge, POMDI is able to provide solutions for many different industrial sectors, the most representative being: automotive, aeronautical, wind power, friction, cutlery, tool machinery, glass, stone, ceramic and optic.

Within these sectors, we strive to supply them with complete solutions for the grinding or machining of different materials, offering a complete catalog of tools for each type of work, always seeking to find the most profitable solution for our clients.

E.E: What’s the news for 2021 about new products?

POMDI: We are currently in a transformation process in which we want to provide our clients with innovative solutions that are not necessarily just tools, but rather devices that can make our tools better, more profitable. We have recently signed a collaboration agreement with an R+D+i research workshop, and we hope to be able to find creative solutions to solve problems in a way that does not exist in the market nowadays.

These improvements include the manufacture of intelligent tools that are able to change parameters in a numerical control machine (CNC machine), thus improving the performance and surface finish of machining.

In addition, we are immersed in a strategic branding process to face the recent future within a totally innovative and creative environment.

E.E: What are the ranges of traded products?

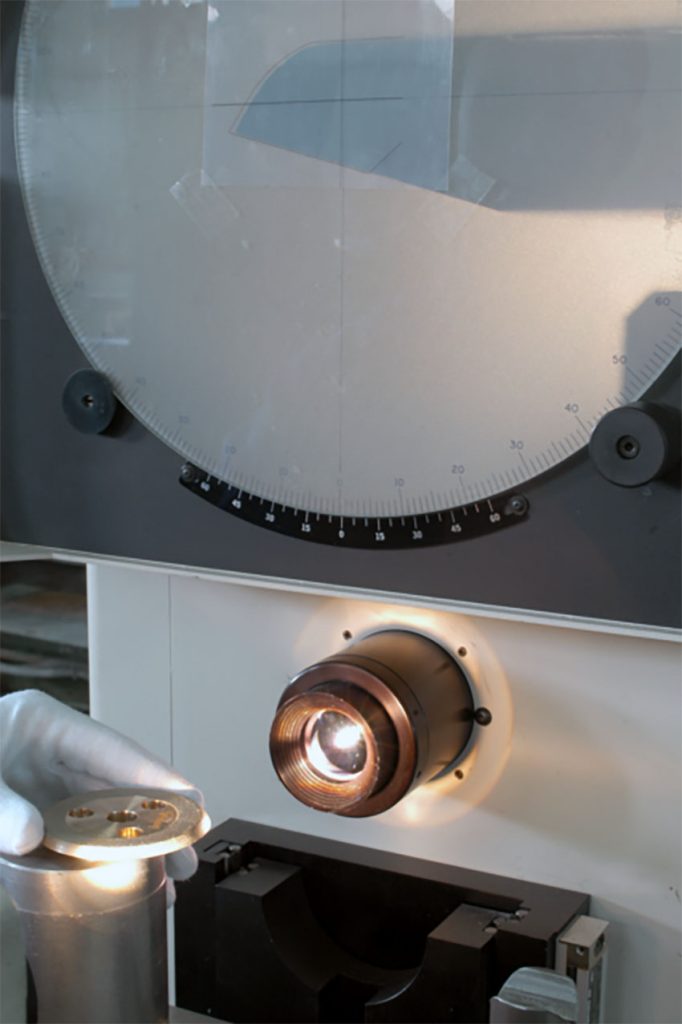

POMDI: We have the capacity to manufacture tools in metallic, resin and galvanic bonding, in any diameter and shape, according to FEPA standards. In addition, we manufacture static and dynamic diamond roller dressers, high precision tools and with very demanding tolerances, used in the diamond grinding of abrasive wheels for precision grinding.

We also manufacture chip removal tools with polycrystalline synthetic diamond (PCD) or polycrystalline cubic boron nitride (PCBN).

E.E: At what stage is the market where you are currently active?

POMDI: As we previously mentioned, we work for very different markets with different behaviours. At the moment, the Automotive and the Aeronautics sector are weaker, due to the electric car market and the COVID-19 pandemic crisis. However, this pandemic is not affecting the Construction nor the Renewable Energy sectors as much.

E.E: What can you tell us about market trends?

POMDI: In the machining industry, there is a trend towards the incorporation of 4.0 Industry and the use of IoT in manufacturing processes. I believe that in the near future the use of analytical data and big data will be very important to improve processes. At POMDI, we are very aware that innovation in this field today will make us much more competitive in the future. There is also a lot of research being done with special materials for additive manufacturing with 3D printers.

E.E: What are the most innovative products marketed?

POMDI: In the stone industry, we specialize in tool sets for polishing kitchen and bathroom countertops on CNC machines. We have a technology that allows us to polish the quartz-based synthetic material with brilliance in just 4 steps, all of them metallic and without the use of resins or abrasive steps, and one extra step of diamond resin for the perfect polishing of natural stone.

In the glass sector, we have patented a magnetic system called 3NEO, where we fulfil three main advantages for cup wheels: a cheaper consumable, tool change in just 2 minutes and a universal system valid for all types of machines, regardless of brand or model.

In the metal sector, we manufacture rollers or diamond dressers to work in plongee or by tracking in CNC machines, reaching extremely low tolerances while attaining the diamond profile.

E.E: What estimations do you have for 2020?

POMDI: Due to the Covid-19 pandemic, in 2020 we have not met the expected objectives. However, in the last 5 to 6 months, the trend has been positive and we predict that 2020 will end upwards. The construction sector is pulling strongly, although the aeronautical and automotive sectors, and of course the hospitality industry, are not. By 2021, we can expect a sustained increase in the economy, and, if the vaccine is effective, we will gradually improve in all sectors, but most likely in 2022, when most industries should be rebounding and accelerating the world economy.