Premier Control Technologies is an instrumentation company specializing in flow and pressure measurement and control, gas systems such as humidification/vaporization and low to ultra-low pump solutions. The company’s product range can be applied to many diverse applications within gas and liquid flow, pressure, temperature and level measurement and control.

Premier Control Technologies is dedicated to not only quality and value but perhaps more importantly to engineering excellence with a passion to collaborate upon unique solutions and “specials”.

Easy Engineering: What are the main areas of activity of the company?

Premier Control Technologies: Our experience is extremely diverse and covers virtually every sector when there is flowing or pressurized gas and liquid. Broadly speaking, our activities fall under eight main categories:

- Applied Science – such as Semicon, vacuum, surface treatment, nanotech, lasers, optical fibres

- Industrial – such as chemical, oil & gas, food & drink, specialty gas, water & waste, agriculture

- Energy – traditional power generation, nuclear, fuel cell and the hydrogen economy, biofuel, solar

- Life Science – pharmaceutical, biotechnology, biochemistry, vetinary, medical, hyperbaric chambers

- Analytical – analyzer manufacturers, sample systems, calibration gas, environmental

- Transport – marine, automotive, aviation, aerospace and space

- Original Equipment – testing, dispensing, dosing, filling, mixing, machines of all kinds!

E.E: What’s the news about new products?

Premier Control Technologies: We are fortunate to have three new products launching this year.

The first is the range of CODA Coriolis Meters and Controllers that are incredibly small an compact, highly specified and, unlike existing products on the market, designed to be virtually immune to transient vibrations. Flow rates are low (less than 1 g/hr to over 100 kg/hr) with accuracy being high (0.2% of Reading for liquids).

The second is our range of flowmeter controlled pumps whereby PID control onboard the flowmeter itself determines the signal to directly control the speed of the pump. Flow rates are therefore extremely accurate, are directly measured and verified, with signal diagnostics being available for system condition and preventative maintenance.

The third range fulfills a gap in the market for extreme applications within gas and liquid flow control. We can now provide solutions to meet highly variable flow conditions, with high pressure and with high temperature. Similarly, we can meet the needs for highly aggressive chemicals and those under super-critical conditions.

E.E: What are the ranges of products?

Premier Control Technologies: Our products include:

Mass Flow and Pressure Control

We help scientists and engineers solve flow problems. When they need fast, accurate readings, PCT are there to help them find a solution and engineer it into their process. Our high level of technical knowledge, combined with our inquisitive nature, ensures that customers get the best solution whilst our empathy and attention to detail makes sure nothing is missed. Our customers work on some of the greatest challenges of the day; we love being part of the solution.

Our mass flow and pressure instruments are fast, versatile, and tough. They make jobs easier and reduce the number of instruments required. People love how easy they are to use and how fast they can be delivered. Our OEM products are focused on high volume, customized solutions with different form factors, communication protocols, or custom features being very welcome. What really sets us apart is the Alicat Lifetime Warranty, unique within the market-place.

There are a great many benefits to the product line although a summary can be seen as:

- 5 millisecond response. Let the customers system respond to changing conditions quickly.

- Multi-parameter. Reduces number of instruments for the application (user) and for stock.

- No warm up time. Speeds the process and makes life easier.

- Multi-communication. Analog and digital on a single instrument lets you plan for the future or integrate with the past.

- Fast lead times. Customers can simply get on with other aspects of their projects.

- Multiple gases on a single instrument. Let the customer reduce number of units needed for stock or future projects.

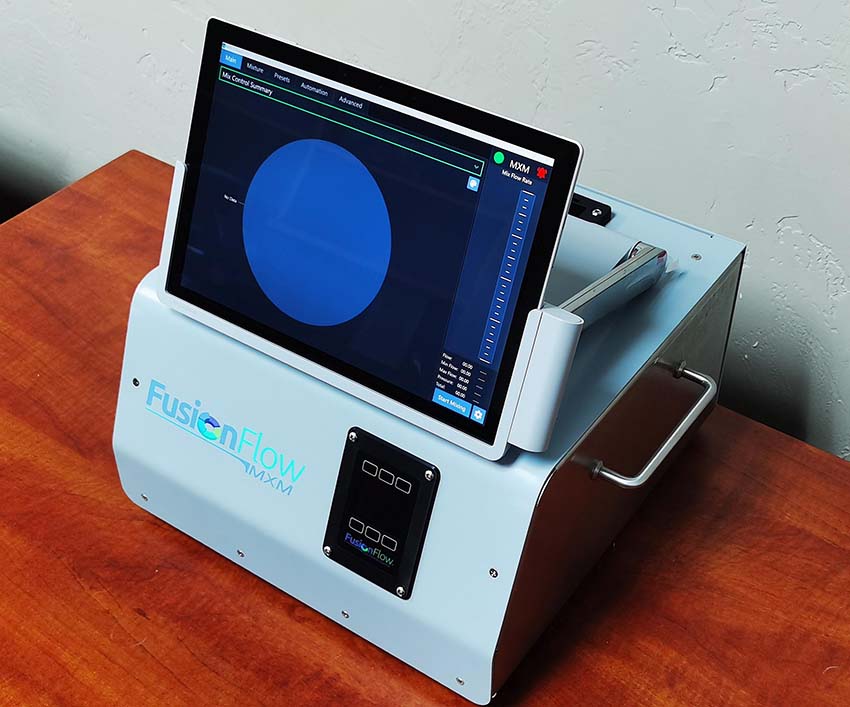

- On the fly gas mixture calibration. Only technology that can do this. Significantly reduces costs for customers.

- Tough. Drop it, throw water through it, just don’t worry about it.

- No conversion factors. No additional errors from actual gas usage versus calibration gas.

The product line consists of:

- Coriolis Flow Meters and Controllers

- Mass Flow Meters and Controllers for Gas.

- Bidirectional Mass Flow Meters and Controllers for Gas.

- OEM Mass Flow Controllers for higher quantity applications

- Single Valve Pressure Controllers for flowing systems.

- Double or Multiple Valve Pressure Controllers for non-flowing, dead-ended systems.

- OEM Single and Double Valve Pressure Controllers

- Flow Meters and Controllers for Liquids.

- Bi-directional Flow Meters and Controllers for Liquids.

- Gas Mixing Systems.

Precision Pressure Control

Our pressure control products deliver reliable performance for some of the world’s most complex process conditions. Our dome-loaded, multiple-orifice technology works in a radically different way, providing solutions for difficult problems in a broad range of industries, including catalysis, oil and gas, fuel cells, and biopharma. The product line consists of:

- Specialist Back Pressure Regulators with exceptional rangeability

- High Pressure and High Temperature Back Pressure Regulators

- Ultra-Low Flow Back Pressure Regulators

- Vacuum Regulators

- Pressure Reducing Regulators

- Solutions for Super-Critical Fluids

- Solutions for Multi-Phase Flow

- Solutions for Very High Viscosity Fluids

- Special Flow Solutions for near impossible applications.

Pump Solutions

Our Pump Series is specifically designed with highly configurable options to meet high-precision applications as seen within science and research whilst also ensuring straight-forward, cost sensitive, solutions for Original Equipment Manufacturers.

The Series, as a whole, covers peristaltic, syringe, micro-piston and micro-gear pumps with flow rate capability ranging from 0.001 microlitres through to 35 liters per minute. Whilst pressure capability is usually determined by the tubing used our piston pumps are rated to 6.8 bar and our micro-gear pumps to 14 bar.

Typical applications cover virtually every segment of industry from Biotechnology and Pharmaceutical, Food and Brewing, Chemical, Water Treatment and Electronics Manufacturing through to Emissions Monitoring, Analytical and the Semiconductor Industry. Examples of where our pumps have been used include laboratory fluid transfer, biopharma filtration, filling and dosing, analyzers, dialysis machines, CEMS systems, IVD machines and so many more.

Mechanical Pressure Control

We offer a comprehensive range of pressure regulators for both liquids and gases with single stage and two stage pressure regulation for low and high pressure processes covering low and high flow rates. Demanding applications such as D.I. water or ultra-high purity gases can also be considered within the range. Options are available for automatic changeover regulators and systems. The core benefits can be seen as:

Safety – Probably the single most important feature of the range. The unique push and lock adjustment handle is pulled “out” when the user is looking to vary the pressure setting but pushed “in”, and therefore locked, during normal day to day use. This eliminates inadvertent re-setting of the pressure and any resulting safety and process issues.

Quality – With its roots firmly within the semiconductor industry, the manufacturing plant lives and breathes quality as a way of life. All regulators are oil-free and are assembled, cleaned, inspected and packed within clean-rooms.

Technical Capability – The range is very strong with solutions for gas and liquids, pressures up to 10,000 psi (700 Bar), temperatures up to 320 C, 316L stainless steel wetted parts, optional Monel diaphragm and an Ultra High Purity range with VCR connections, 5 Ra surface finish, a springless design, tied diaphragm and captured vent.

- Special Solutions

- Gas Mixing Systems

- Dosing Systems

- Blending Systems

- Vapor Generation Systems

- Humidification Systems

E.E: At what stage is the market where you are currently active?

Premier Control Technologies: We are fortunate to be active within a great many markets and whilst several have not yet picked up to pre-pandemic levels most are already there. Three particular areas where we have been especially busy are (a) the Hydrogen economy including tanker and dispenser flow verification and, of course, fuel cells, (b) the design and testing of ventilators and (c) pharmaceutical/vaccine development and production. The high technical specification and beneficial price point of each our mass flow controllers, Coriolis controllers and peristaltic pump solutions ensures that we are ideally placed to meet the needs of these markets.

E.E: What can you tell us about market trends and what estimations do you have for 2022?

Premier Control Technologies: As mentioned above, we are very fortunate that our flow and pressure expertise is applicable across a great many markets. As we continue to listen to what our customers are asking and as we continue to innovate, we see a very bright future ahead of us. Traditional markets are growing, new markets are emerging and the national focus on science and development is certainly helping.