Founded in 2013 in Grenoble, France, Primo1D develops and manufactures thread-like UHF RFID tags under the E-Thread™ trademark.

Primo1D debuted on the Minatec Campus of the CEA’s research and development center in Grenoble, which ranks in the Top 5 of Forbes’ most innovative cities in the world. This environment gave Primo1D the benefit of a technological base for the implementation of its processes and equipment, and the qualification of its products.

In 2021, the company moved to a new site to accommodate increasing demand for production of its RFID thread.

Easy Engineering: What are the main areas of activity of the company?

Primo1D: Primo1D offers embedded RFID technology that addresses the challenges of data and data reliability in monitoring the lifecycle of textile and industrial products. The company helps its customers to drive their digital transformation through a technological innovation: E-Thread™.

In their traditional form (label), tags are not totally embedded and undetachable without denaturing assets and without getting degraded during their lifecycle.

Primo1D has rethought RFID tags form factor in order to embed them in many original assets (such as garments, tires, electrical cables, etc.) during manufacturing, in a reliable and durable way.

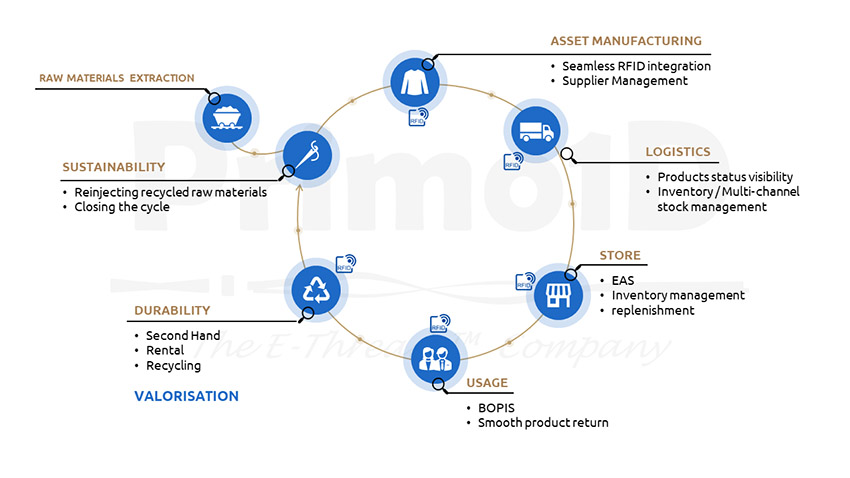

Pieces of connected assets combined with their digital twins can generate value throughout the product lifecycle.

E.E: What are the ranges of products?

Primo1D: Today, Primo1D proposes different versions of the E-Thread™ tag according to the market.

A strip-like E-Thread™ tag, made for textile; this tag is designed to be embedded into garments overlock and is compatible with overlock machines. The strip-like tag can be used for retail in a variety of RFID applications such as brand protection, supply chain management, inventory, omnichannel/BOPIS/Ship from store strategies, loss prevention, product returns, and the circular economy.

Another version of the tag is available for workwear (corporate garments, PPEs, etc.) with lifecycle tracking applications (washing, maintenance, repairing, etc.).

The Primo1D tag for textile undergoes up to 100 domestic washing cycles.

A yarn-like E-Thread™ tag made for industry 4.0; it is designed to be embedded in many industrial assets, such as tires, hoses, electrical cables, pipes, ropes, plastic and composite parts, etc.

This tag can address applications such as unique product identification, authentication, manufacturing and supply chain management, repair, and maintenance up to recycling. The combination of an EPC/RFID unique digital identifier with an embedded, non-detachable and durable product generates its digital twin, reliably linking it to the cloud.

E.E: What’s the news about new products?

Primo1D: In 2022, Primo1D scaled-up to industrial production of E-Thread™ tags and is now able to address big volumes pertaining textile distribution.

This timing matches EU recent communication about the European strategy for sustainable and circular textiles that will introduce mandatory digital passports that embedded RFID can support.

E.E: At what stage is the market where you are currently active?

Primo1D: RFID has already proven itself necessary to the textile market (fast fashion and professional garments and linen). It helps retailers to optimize their supply chain and increase availability in stores, but it also supports professional garments and linen management.

Many sectors of industry are also already working with RFID solutions to connect their assets to the cloud and shift to industry 4.0.

For instance, the tire industry has been working on the use of RFID in tires for a better follow-up of their lifecycle and to bring new business models, such as renting.

More and more sectors are willing to use RFID and take advantage of its benefits, but many of them are limited with classical RFID tags that do not fit the shape of specific assets (electrical cables for instance). With E-Thread™ form factor, Primo1D can overcome these limits in many assets.

E.E: What can you tell us about market trends?

Primo1D: In the 2020’s, particular heed is given to circular economy and waste limitation. RFID has always been an ideal candidate to overcome these issues, as it helps track down assets, optimize their lifecycle, tracking them down along their value chain, and, thus, avoiding the production of unnecessary new assets.

Regarding the textile industry, France (along with the AGEC law) and Europe (along with the circular economy action plan) are pioneers on these issues and businesses abroad are likely to comply in order to keep addressing European markets.

Recycling is one of the main pillars in the circular economy and needs technical efficient solutions to sort materials. Primo1D’s embedded RFID is an affordable key solution to offer sorting automation as a digital passport.

E.E: What estimations do you have for 2023?

Primo1D: For the next month, we will keep delivering our customers with different version of our solution and we will pilot new POC to expand our market and accelerate adoption of our technology.