pro-micron is a medium-sized company in southern Germany with around 50 employees from a wide range of disciplines. In the field of sensor system solutions, the company has taken a leading position in recent years in cutting force measurement as well as in wireless and passive temperature measurement.

Founded in 2002, the company supports partners and customers worldwide to digitalize their processes and is significantly involved in paving the way towards the smart factory. World-renowned companies such as Bosch and Miele have relied on the expertise of pro-micron GmbH for years.

Easy Engineering: What are the main areas of activity of the company?

PRO-MICRON: The company’s product division is divided into two parts.

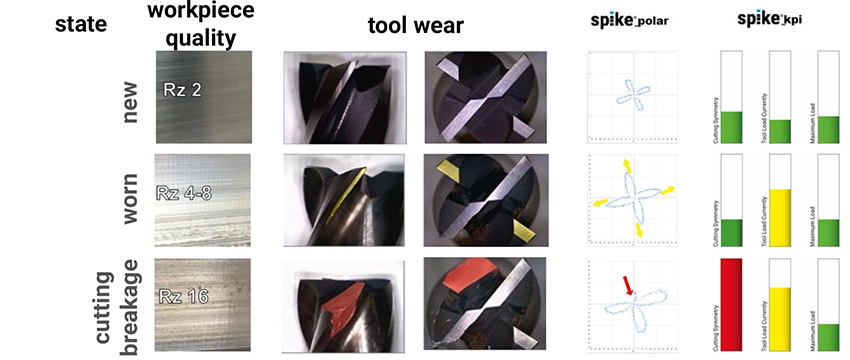

A significant part of the product portfolio of pro-micron GmbH is the product spike®. This is a software/hardware solution for measuring cutting forces. With the innovative spike® solution, pro-micron GmbH offers its customers the tool to make their CNC machine sensitive. Particularly noteworthy is the individual cutting-edge monitoring of spike®, which allows the condition of each individual sheath on the tool to be visualized and evaluated during the process. This solution enables customers to monitor, visualize and optimize their processes. In November 2020, pro-micron was awarded the Bavarian Innovation Prize for its spike®_inspindle.

The second product segment builds on wireless and passive temperature measurement. Here, pro-micron implements solutions in the food & beverage sector as well as in the automotive sector. By using temperature measurement from pro-micron, it is possible to realize temperature measurement at up to six different points without the use of batteries or cables.

E.E: What’s the news for 2021 about new products?

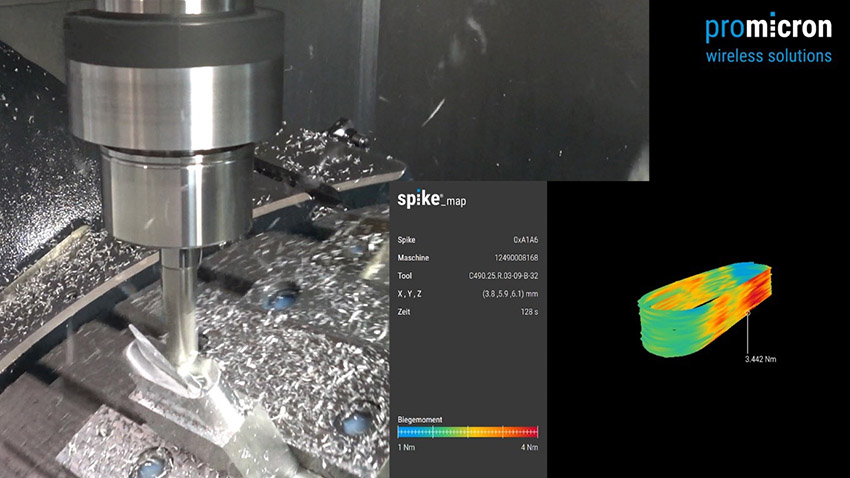

PRO-MICRON: In the area of cutting force measurement, the product innovations for 2021 include the spike®_map, which makes it possible to generate a digital twin of the component during the cutting process. By creating a digital twin in combination with the cutting force measurement, quality monitoring can be introduced inline, which shows the user exactly where his product has a defective surface. This allows the user to react inline and eliminate the need for an expensive and time-consuming downstream check.

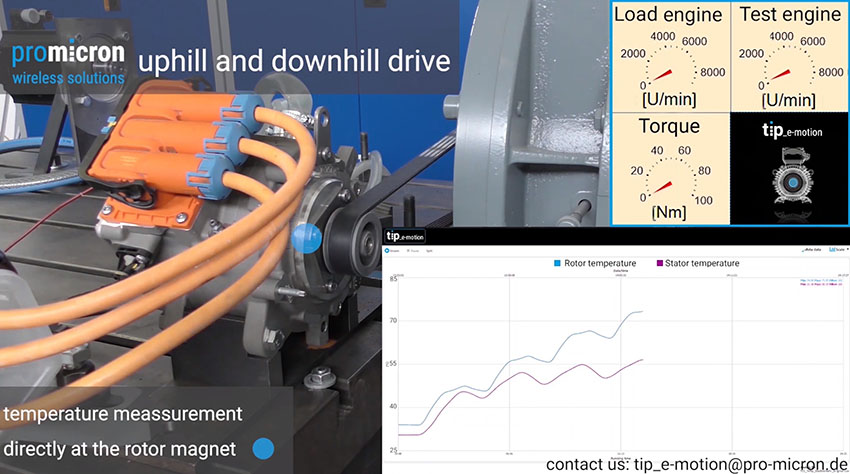

Another new product is tip_e-motion. This is a system for temperature measurement in electric motors. The special feature here is that pro-micron has succeeded in mounting the sensor directly on the rotor shaft in the magnetic field. With this innovation, the electric motor can be monitored to prevent overheating and a possible total loss of the motor.

E.E: What are the ranges of products?

PRO-MICRON: pro-micron offers a wide range of products in the field of sensor systems from smart cutting force measurement to wireless and passive temperature measurement.

In the area of smart cutting force measurement, pro-micron offers its customers both inline monitoring spike®_easyinline and the spike®_expertline solution for optimising cutting processes. By using sensor technology, pro-micron has succeeded in giving its customers a tool with which they can digitalize their processes with the help of sophisticated analysis software and artificial intelligence. Through this application, costs in production and development can be reduced and thus costs saved.

In temperature measurement, pro-micron offers its customers individual solutions. With the tip product, pro-micron’s partners and customers can measure the temperature at up to six measuring points. The special feature of tip is that the system does not require a battery or wiring and thus enables the user to measure temperatures in places where it was previously impossible or difficult to do so.

E.E: At what stage is the market where you are currently active?

PRO-MICRON: Digitalization is a true megatrend and pro-micron is in the midst of it. We offer our partners and customers solutions with which they can digitalize their company or product. Our product spike® in particular offers its users the path towards Industry 4.0 and the smart factory. What can you tell us about market trends?

E.E: What are the most innovative products marketed?

PRO-MICRON: All our products captivate with an innovative character. As already mentioned, we are very proud of our award, which we received in November 2021. The Bavarian Innovation Award shows us that we are on the right track and that with all our products we offer our partners and customers solutions with true added value.

Innovation is very important to us and we work very closely with universities and research institutes. We would like to particularly emphasize our cooperation with the Kempten University of Applied Sciences, which operates its Technology Transfer Centre on our premises. Close contact with customers and partners along the value chain plays an important role for us. Understanding the needs of our customers and the active exchange with research institutes offers us as a company an unbelievably high level of innovation.

E.E: What estimations do you have for 2021?PRO-MICRON: We see the current crisis as an opportunity for digitalization. The last year has shown many companies how fragile analogue processes often are and how they can be significantly improved through innovative and sustainable technologies. That is why we are looking positively into the future and look forward to further exciting projects together with our partners along the machining value chain