ProCom GmbH is a successful family business. Founded in 1977, its operations comprise two business units: energy and automation.

ProCom Energy offers consulting services for energy production and energy trading. ProCom studies make chances and risks of decisions transparent. With process and IT knowledge, ProCom accompanies the implementation of strategies, all the way through to daily operations. With IT solutions, data services and market information from ProCom, energy portfolios can be optimally managed across all time horizons and markets.

Easy Engineering: What are the main areas of activity of the company?

PROCOM: ProCom Automation has been developing custom automation solutions for machine manufacturers in the cutting and separating industry for over 35 years. The development specialists at ProCom equip machine series with advanced CNC software and hardware, as well as CAM solutions and provide appropriate drive technology from world-renowned manufacturers. The products consist of from parts and software components “Made in Germany”. Sound expert knowledge of various processes such as waterjet cutting, laser and Plasma cutting, foam contour cutting and textile cutting lead to highly efficient and automation solutions adapted to individual requirements. ProCom Automation invests in international markets with future-oriented products and services around industry 4.0.

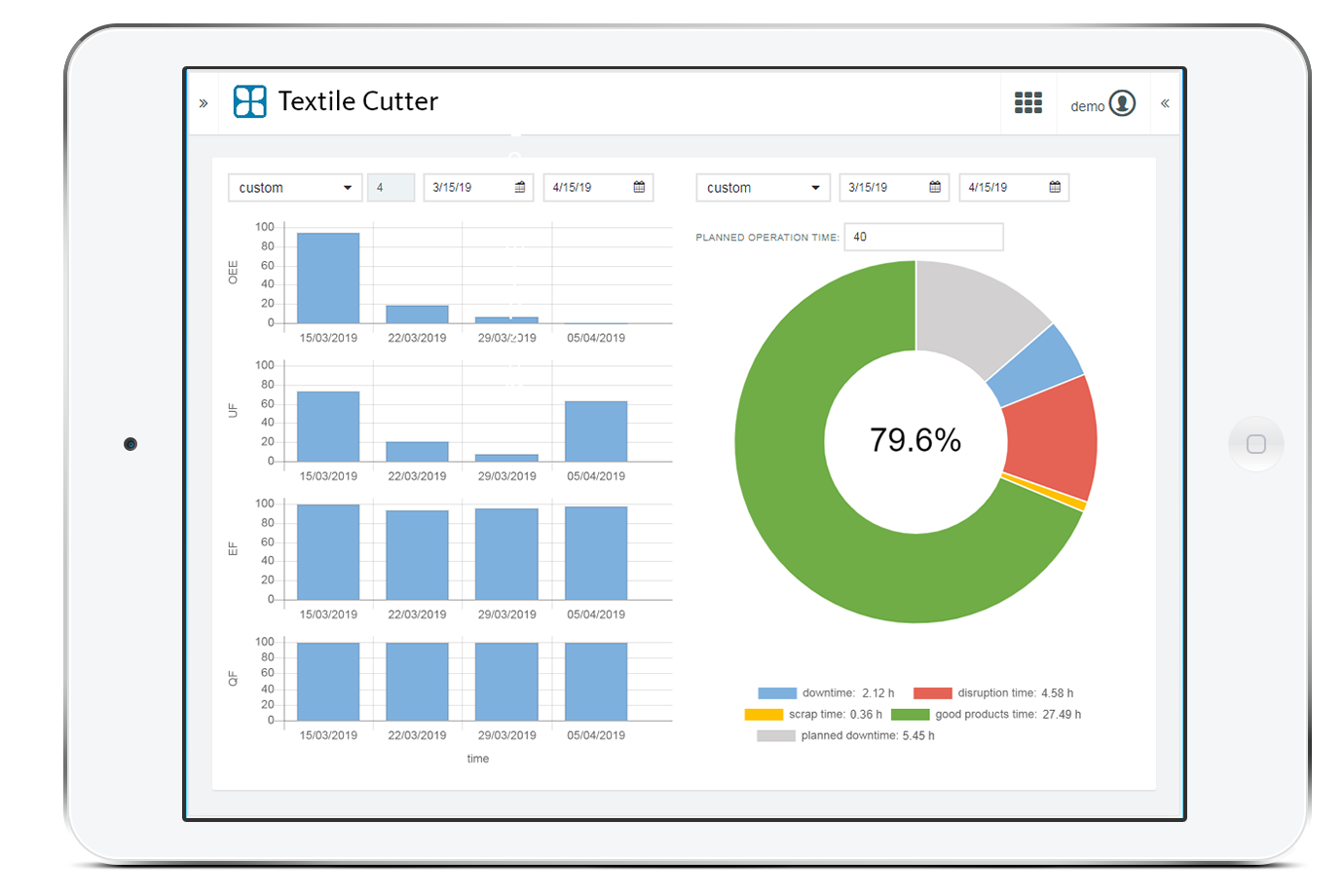

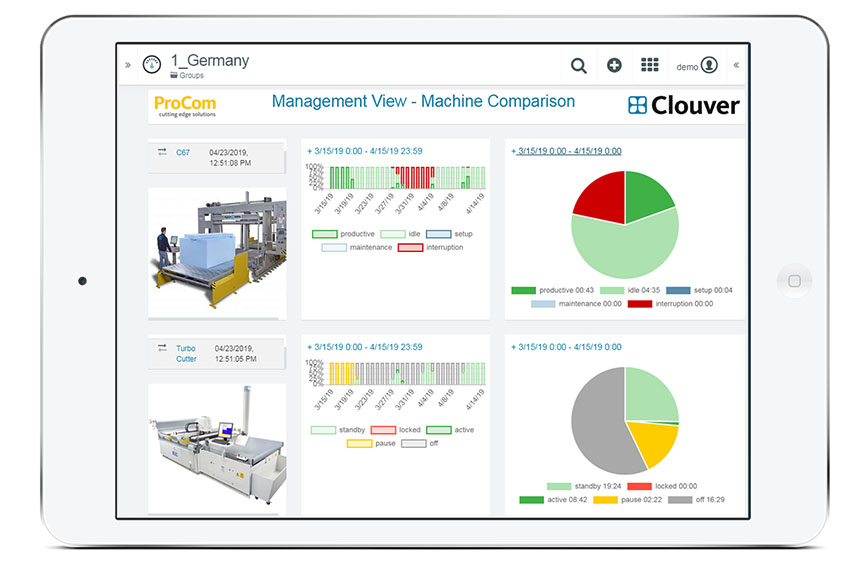

The Industry 4.0 solution Clouver, the production can easily be linked with its digital image in real time and across multiple locations. This makes potentials visible and production more efficient. Clouver helps identify hidden production costs and minimize downtime. Customers thus receive a comprehensive real-time insight into all production processes. With the Dashboard app, users can customize their widgets with the functions that are important to them, in order to achieve the greatest possible work efficiency. The extensive production data can be easily exported, which makes analysis, reporting and production planning much easier.

E.E: What’s the news for 2020 about new products?

PROCOM: A new product is the Clouver SmartKit. It is an addition to ProCom’s industry 4.0 platform Clouver, which enables a quick return on investment, usually within a few months. Instead of the data readout via software interface or gateway directly from the machine controller, the Clouver SmartKit uses intelligent sensor technology. Important data from machines – whether old or ultra-modern – can be quickly determined with minimal installation effort. The machine operator can manually refine this data via a touch panel, for example by selecting reasons for downtime. In Clouver, users then find a live digital image of their production, visually prepared in individually designed dashboards. Initial production optimization measures can then often be initiated immediately, so that users can quickly benefit from higher plant efficiency. Clouver SmartKit offers an quick and easy access to Industry 4.0, especially valuable in times of Corona crisis and economic uncertainties.

E.E: What are the ranges of traded products?

PROCOM: The ranges are:

- Hardware: CNC300pro, CNC300eco, CNC300ET https://procom-automation.de/en/cnc-cam/cnc300/hardware/;

- CNC Software: ergoCNC https://procom-automation.de/en/cnc-cam/cnc300/ergocnc/;

- CAM Software: ergoCAM;

- SPS, PLC;

- I4.0: Clouver, Clouver SmartKit www.clouver.de;

- drive technologies: Bosch Rexroth system integrator.

E.E: At what stage is the market where you are currently active?

PROCOM: With respect to the coming huge effects of digitalization, networks of things please keep an eye on that and be aware that every business even yours will be affected.

Gartner’s hype cycle describes a 5-stage pattern that almost all new technologies follow:

- A technology trigger introduces new possibilities, which capture imagination and create a rapid rise in expectations. (“IoT is a breakthrough!”);

- Industry 4.0 quickly became a buzz word and reached a peak of inflated expectations – the “hype” overshoots the reality of what’s possible;

- Reality comes into the game. Expectations drop like a rock;

- But technical development moves on and chance steadily improve, people begin to figure out realistic applications. This is the slope of enlightenment: Industry 4.0 is useful in these cases…”;

- Welcome to the plateau of productivity. “Digitalization is a fact of life. Here’s how we use it.”

E.E: What can you tell us about market trends?

PROCOM: We are at the point where people figure out that IoT becomes not only useful but also necessary to keep alive within competitive markets.

One of our clients has done his first steps within digitalization years and years ago. He runs a lot of machinery within his facility. One of his statements was “How can people operate their machinery without a monitoring tool? For me it is important to make decisions based on facts and discuss with the production manager and operators more than based on a smart guess”.

Software systems need to be connected. Time for isolated solution is over. It is never to late to start digitalizing and it is a good idea to keep up. Corona taught us who is digital survives.

E.E: What are the most innovative products marketed?

PROCOM: ProCom delivers solutions, therefore, we prefer to give you our most recent success story as an example. It is about a mattress manufacturer who owns multiple facilities all over Europe. Because he is based in Spain travelling is a challenge and a potential risk. He started to connect all his facilities and it’s most important machinery to Clouver last year. From now on he monitors his machinery while being at home safely. His local operators welcome that monitoring. They receive direct feedback from what they do “live KPIs” and started a positive challenge between shifts. Positive because they like to do a good job, while creating “green status bars” by keeping machines running according to what is scheduled. If something is going wrong they are able find out what happened and solutions. Of course, trainings were given to everybody involved while introducing Clouver to make them feel comfortable.

“It is about saving our subsidiary and improving our processes continuously. We all stay together to compete globally”, says the facility manager.

E.E: What estimations do you have for 2020?

PROCOM: 2020 was tough for economy and society. We are convinced Digitalization is the key. Corona will leave steadily but digital companies will stay. “75% of all efforts are about defining the digital business concept. Just a fraction part is about turning it into reality” says Matthias Winkelhoch, Key Account Manager IoT. “ProCom’s target is to support companies on evaluations and turning individual business concepts into reality. 2021 will be another busy year for all of us. Let’s get started!”.