prosimalys is an engineering service provider for the metal forming and forging industry, founded in spring 2020 by the long-time Hirschvogel Automotive Group Vice President of Advanced Engineering, Dr.-Ing. Hans-Willi Raedt. The company provides services in the field of simulation, materials and analyses.

Interview with Dr.-Ing. Hans-Willi Raedt, Managing Director and Shareholder of prosimalys.

Easy Engineering: What are the main areas of activity of the company?

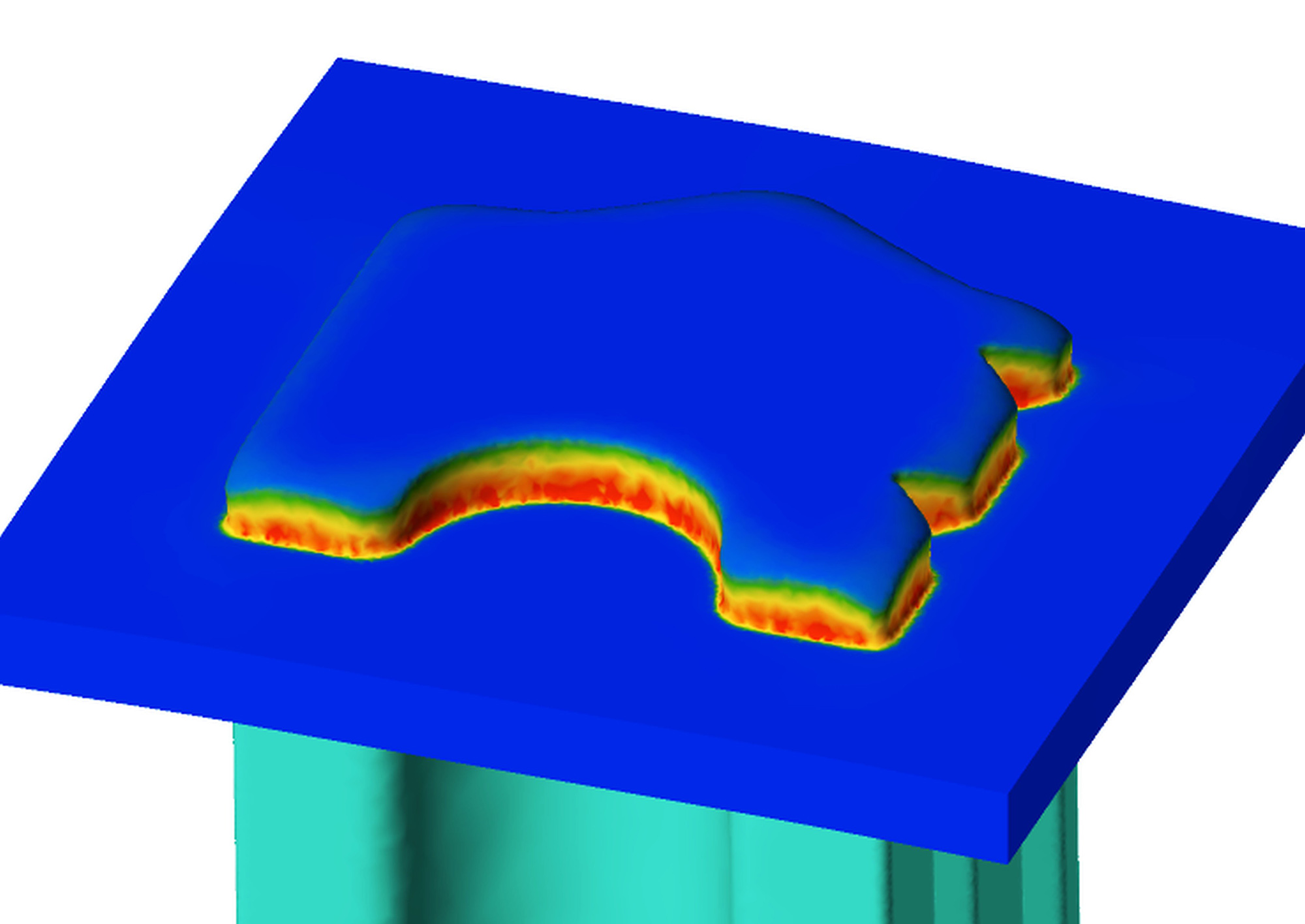

Hans-Willi Raedt: prosimalys provides engineering services like simulations, consultancies about forming and forging processes and material related questions.

E.E: What’s the news about new products?

H.W.R: prosimalys services are in high demand. The metal forming and forging industry is pressed to save cost and currently very strongly energy. With the right choice of metal material / steel and an according design of the manufacturing route, a lot of gas energy can be saved and product can be manufactured at reduced cost.

Dr.-Ing. Hans-Willi Raedt, Managing Director and Shareholder of prosimalys.

E.E: What are the ranges of products?

H.W.R: prosimalys provides consultancy services concerning forming and forging processes, concering forming and forging materials, delivers simulations of metal forming processes and sells the simulation package QForm UK in Germany and surrounding countries.

E.E: At what stage is the market where you are currently active?

H.W.R: The market served by prosimalys has been active for a very long time. The manufacturing industries in forming and forging are well developed. However, the application of knowledge from materials via the manufacturing processes with regard to the final product shows a very promising growth potential.

E.E: What can you tell us about market trends?

H.W.R: The target industry of prosimalys has always needed to save cost. Currently, it is highly pressed to save energy, mainly in the form of gas used for heating and heat treatment processes. Advanced knowledge of steel material and manufacturing processes with regards to the properties of the final product is in high demand.

E.E: What are the most innovative products marketed?

H.W.R: Saving energy, gas, mass, assembly space and cost at the same time.

E.E: What estimations do you have for 2022?

H.W.R: prosimalys expects further growth by applying its comprehensive knowledge about materials, simulations and the industry.