REDEX Group is a truly European engineering group specialized in supplying advanced solutions for high precision industries with the aim to be always at the top of the few world leaders in each of its high demanding specialties. REDEX Group focuses on three main industries: Machine drives, Strip processing technologies & Precision rolling mills, and gathers REDEX, MEROBEL, BÜHLER, UNGERER and BWG technologies.

REDEX Group’s complete products portfolio is 100% made in Europe.

- R&D and design are fully operated in its German and French technical offices;

- Production is managed in its 3 European high-tech production plants;

- Full commissioning is supported all over the world by its high skilled engineering teams and local fully trained correspondents.

Easy Engineering: What are the main areas of activity of the company?

REDEX: Based on an in depth understanding of all types of metals, from low carbon steel to the most advanced alloys, REDEX Group Strip Processing Technologies business unit offers a wide portfolio of equipment and subassemblies dedicated to the world class OEMS and production plants aiming for the highest added values.

REDEX Group is recognized as a key partner for major precision strip producers. We are truly experienced in supporting our customers all over the world. We export to more than 50 countries, mainly Asia, the Middle East, South Africa, the USA and Europe. And our service centers in Asia, America and Europe enable us to cover support needs: from advice, training, or spare parts, or even to larger investment requirements, on short notice.

Since we have the expertise to provide strip processing equipment and finishing lines, our stated goal is to help each of our customers and partners to get the most out of the technologies in which they are investing, and thus to achieve better performance.

E.E: What’s the news about new products?

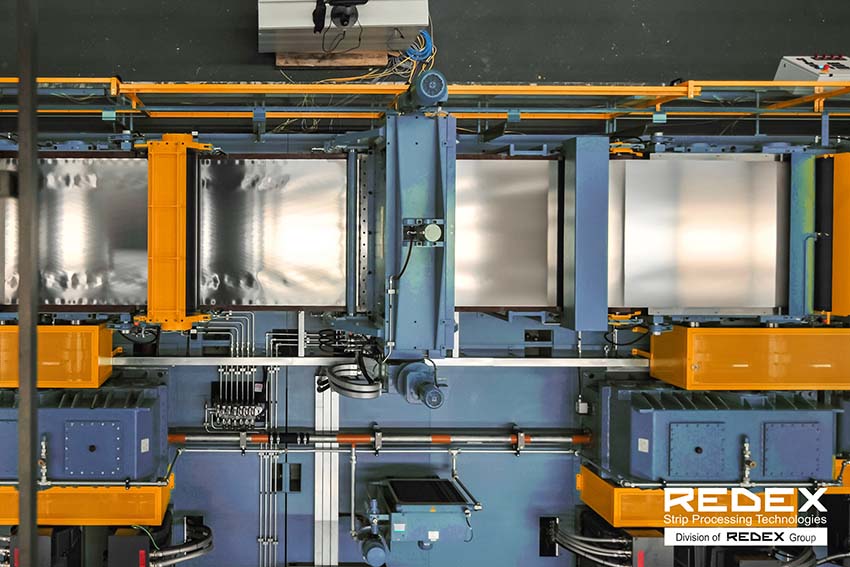

REDEX: New Multi-axes robot for 20 high mills tools handling

Thanks to the REDEX Group’s decades of experience with high precision stainless steel strip producers and its long relationships with leading 20-high mill builders, REDEX now offers ROBEX®, a major innovation to carry out the handling of backup lines from and in 20-high mills safer and faster than conventional solutions.

ROBEX® is the new multi-axes robot, designed and manufactured within the REDEX Group, which provide to customers:

- A long life time of the housing and back-up assemblies

- Reduced shut down for maintenance

- Safety during maintenance operations

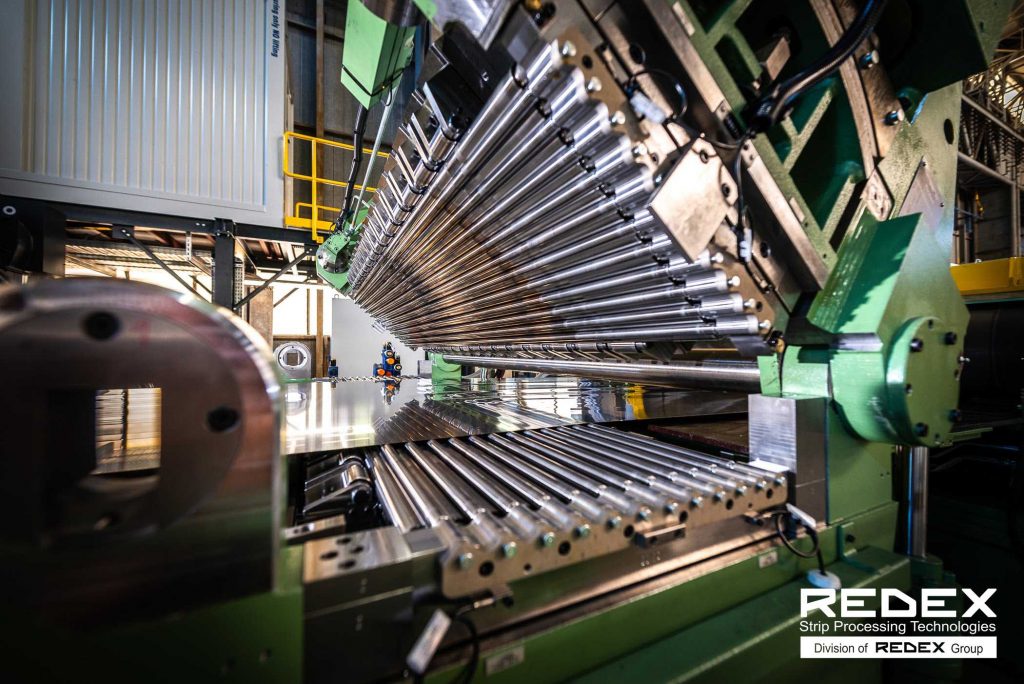

New Multiroll leveler with full automatic new flatness control

Since REDEX Group acquired Ungerer & BWG technologies, our group has the most complete portfolio of solutions for strip leveling.

We have more than one solution for each case and we customize our standard equipment to the customer performance needs.

Taking into account the hundred years of cumulated experience, REDEX Group has been developing a new multiroll leveler dedicated to the hardest or most sensitive foil finishing.

This new equipment has all necessary functions to process any kind of strip width and eliminate all possible deffects.

The leveler is driven in a full automatic mode and doesn’t request any skilled operations due to our latest automatic flatness control called UMS Pro technology.

The flatness results on the strip after processing are 10 times better than the strip at the entry and reach in most of the case 1IU.

E.E: What are the ranges of products?

REDEX: Beyond its own skills and long experience, the acquisition of Ungerer GmbH in 2017, and more recently of the patents of BWG GmbH, and the integration of its most talented engineers into its teams, have made the Redex Group a true European engineering company. In the specific field of steel, the Group’s enriched offer enables it to support its customers in a very large number of specialized processes.

To mention only the most significant ones:

- The most complete range of stretch bend levelling solutions.

- Backing assemblies and maintenance solutions on 20-high mills.

- Entry and exit of processing lines.

- Any type of shears.

- Scale breakers.

- Skin pass mills.

- Cleaning sections.

- Coating section and flotation drying.

E.E: At what stage is the market where you are currently active?

REDEX: The current installed steel production capacity is huge. The very large investments made over the last decade mean that most of the existing equipment is unfortunately not used to its full capacity. And it is foreseeable that future mergers of steel producers will lead to the shutdown of some lines or to the modernization of others in order to increase efficiency and improve quality. The REDEX Group is well suited for this type of mission, with more than 50 qualified engineers working with customers to develop unique solutions to upgrade standard equipment or to bring ageing equipment up to new standards.

E.E: What can you tell us about market trends?

REDEX: We are seeing very strong demand for precision stainless steel strip or copper alloys driven by new technologies such as batteries and fuel cells. Demand for stainless steel & copper alloys continues to grow.

Our customers are also looking for solutions to improve their competitiveness in the market place, including upgrading their existing processing or finishing lines.

Knowing by experience its strong resilience and its innovative capability, we have no doubt that the steel industry will continue to grow and renew itself as much as necessary to solve these challenges and still be in position to supply the world with one of the most necessary products for its development.

E.E: What are the most innovative products marketed?

REDEX: Industry 4.0 is certainly the most innovative solution which will be required by end users.

REDEX Group has started to implement such solutions in our proposal including sensors, data acquisition, IA.

This help end users for predictive maintenance but also to define the right setup of the equipment for the best performances.

We are taking a step forward by giving our customers the possibility to use the data recorded on their equipment, not only for monitoring instantaneous performance, but also and above all to enable them to draw on past experience to improve their processes and efficiency.

E.E: What estimations do you have for 2022?

REDEX: Since the beginning of 2021, steel, copper and aluminum industries have been pulled by a huge demand of the market.

To follow the market, our customers have been looking for more performance: higher productivity, better quality, they asked modernization of their equipment or new dedicated lines to process at higher speed, thinner & highly precise gauges, shiny brightness.

REDEX Group is renown leader in Engineering and able to provide key and advanced technologies for the most demanding industries.

The current order intake has been at a historical level for several months. We are working hard to meet specific needs of our customers despite the lead time increase we are facing on raw material, electric and electronic components. We expect an important increase (2 digits %) of our sales in 2022.