Robotnik is a leading European company in mobile service robotics. Its activity is focused on the development and manufacture of autonomous mobile robots and manipulators for different applications in both industrial and academic fields: inspection, mobile handling, inventory, transport or logistics, among others.

Since the start of its activity in 2002, it has sold more than 5,000 robots in 50 countries around the world and has participated in more than 60 European R&D projects.

Robotnik has its own R&D department in mobile service robotics and a multidisciplinary engineering team qualified in various fields such as industrial engineering, mechanics, telecommunications and software development.

Since January 2023, Robotnik is part of United Groups Group (URG) headquartered in Bochum, Germany. United Robotics Group unites young service robotics companies into a unique ecosystem by bundling hardware and software expertise under one roof. URG creates as the CobiotX company the 3rd generation of robotics – robots for humans.

Easy Engineering: What are the main areas of activity of the company?

ROBOTNIK: Our activity, as a leading mobile robotics company in Europe, focuses on the development and manufacturing of mobile platforms and mobile manipulators, as well as the development of engineering projects and R&D projects in mobile service robotics.

Although we have autonomous mobile robots for different areas but the truth is that the 3 areas where Robotnik is strongest are: inspection, mobile manipulation and transport. The fact that our robots have the ability to move and perform tasks autonomously and intelligently makes them particularly useful in these 3 verticals.

E.E: What’s the news about new products?

ROBOTNIK: Robotics is becoming established in many traditional and new industrial sectors. The key to automating processes intelligently and cost-effectively is mobility. What our customers appreciate is that all our AMR and mobile manipulators have the ability to operate in one or different locations and perform single or multiple tasks, as appropriate. This means that the return on investment is quickly measurable.

In addition, Robotnik’s portfolio offers a wide range of robotic solutions to suit every need. For example, the different load capacities range from 50 kg for the RB-1 BASE to 1T for the RB-ROBOUT, including 200 kg for the RB-THERON. Also, you can find different speeds, handling options, sizes, environments (indoor/ourdoor), etc.

E.E: What are the ranges of products?

ROBOTNIK: Our portfolio includes collaborative and autonomous mobile robots for different applications both in indoor and outdoor environments.

Within Robotnik’s robot range you can choose between Autonomous Mobile Robots and Autonomous Mobile Manipulators with different load capacities, autonomy or speed.

Thanks to Robotnik’s experience of more than 20 years in the mobile industrial robotics sector, as well as the versatility of our industrial robots, it is possible to offer a tailored solution for your company.

Mobile industrial robots are a useful tool to create safer, more efficient workspaces and achieve higher productivity.

E.E: At what stage is the market where you are currently active?

ROBOTNIK: At every point in history, humans have developed the tools necessary to carry out their work. Now, mobile robotics is the key to Industry 4.0. It is no longer just about automating industrial processes, but about intelligent automation in which mobile robotics optimizes production and profitability, and makes tasks easier for employees.

Collaborative robotics is not here to replace humans, but to provide better working conditions.

Inspection robotics, which is one of Robotnik’s focusing areas, is an essential work of many industrial sectors: tunnels, refineries, old buildings, electrical substations and other environments that are difficult to access and dangerous for humans. For such inspection tasks, the use of mobile robots such as the SUMMIT-XL or the RB-VOGUI has grown significantly.

E.E: What can you tell us about market trends?

ROBOTNIK: One clear market trend is robotics for inspection.

According to International Federation of Robotics data, robots for inspection tasks such as those operating in buildings and construction environments, for example, grew by 21% in 2021 from the previous year.

This drive is due to the progress of adjacent technologies such as Artificial Intelligence, 5G connections or the Internet of Things. The development of these technologies is important as they enable improvements in robot autonomy and network limitations.

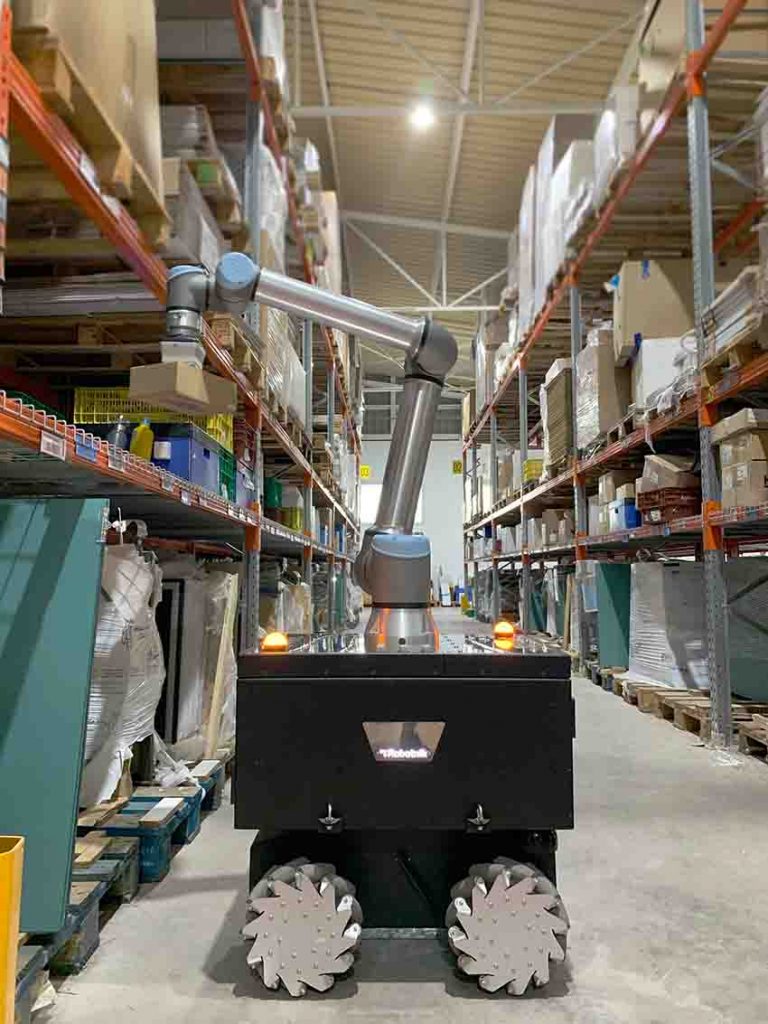

Another trend we detect is with respect to autonomous mobile manipulation, an area in which Robotnik is a pioneer. Mobile manipulators are mobile platforms that integrate a robotic arm and can thus carry out material or part handling tasks in one or multiple locations. For example, the RB-KAIROS+, which are already used in numerous logistics environments to perform tasks such as Pick & Place, Fetch & Carry, Machine Tending, inspection and verification or operations with large parts.

E.E: What are the most innovative products marketed?

ROBOTNIK: Each Robotnik robot is optimally suited to meet specific automation needs, so it is difficult to highlight only a few specific products. But certainly, the RB-KAIROS+ mobile manipulator is unique in terms of development. Its versatility, the omnidirectional mobile platform, the ease of commissioning for the customer and its technical capabilities make it our flagship mobile manipulator.