ROBUSO is family-run company in 4th generation. Since 1919, high-quality scissors for industrial use are handmade in Solingen. For many decades, ROBUSO has specialized in the production of scissors for the composite market.

In addition to their handmade shears, the company offers a very wide range of many other cutting solutions: from hand-held electric or battery machines to OEM/build-in machines to CAD cutters for fully automatic digital cutting.

Easy Engineering: What are the main areas of activity of the company?

ROBUSO: We have been very strongly represented in the composite market for many decades. Our biggest customers are the worldwide manufacturers of rotor blades for the wind power industry.

Other very successful markets are the maritime and automotive industry, but also safety clothing and aerospace.

Outside the big composite cosmos, we supply our shears wherever natural fibers are cut.

These are e.g. manufacturers of textiles, alteration tailors, theaters, etc.

With the purchase of 2 Solingen companies, in the past 1 ½ years, that manufactured hair scissors, ROBUSO is a little back to the roots. Hair scissors and razor blades were the first products ROBUSO made before specializing in industrial scissors. Now we are very proud to distribute the hair scissors of the brands NTS and Stancanelli through our subsidiary NTS-Solingen.

E.E: What’s the news about new products?

ROBUSO: It is not directly a new product, but our very popular ROBUSO battery powered shears have received many small upgrades.

In addition to the improved BA45 blade, which promises an even better cutting result and an even longer service life when cutting glass and carbon fiber, the replaceable Li-Ion battery has also received an even higher capacity and power (18V/6Ah).

What can our ROBUSO battery shears do?

This great machine cuts (depending on the installed blade) easily several layers (composite) material. An extreme example are our customers from the wind power industry. In the production of rotor blades, the machine cuts between 10 and 15 layers of fiberglass with a grammage of 1,200 gsm at a time. Although this places extreme demands on the machines, it is possible …

For customers who do not have to cut so many layers at once, there has been the little brother of the ROBUSO cordless shears for some time. Our ROBUSO Power Cutter R1. This machine weighs only 1.25Kg which means half weight compared to the „big” BA45, but it is still able to cut up to 5,000 gsm of e.g. glass or carbon fiber.

Of course, we also have blades for these machines to cut e.g. Aramid or Dyneema.

You can get a good impression of the machine with our product videos, which can be found in our YouTube Chanel “ROBUSO1919” or directly here:

E.E: What are the ranges of products?

ROBUSO: We are manufacturer of our ROBUSO scissors in Solingen, Germany and that for more than 100 years.

Our scissors are produced by skilled workers with many small production steps by hand. This characterizes our quality and we are very proud of it.

A ROBUSO scissors is, before it leaves our house, among other things, tested several times for a good, easy and smooth opening and closing of the scissors. Another important part of our quality control is the cutting control. All of our shears for the composite market are tested on aramid without exception, to ensure that even customers with the most difficult materials receive a good and satisfactory cutting result.

Our shears are forged from C60 carbon steel and hardened to a hardness of approximately 60 HRC (Rockwell). This makes them very hard and very durable. For an always precise cut, up to the tips, all scissors for technical textiles, are always micro-serrated. This micro-serration prevents the fibers from slipping away from the cutting edge during cutting.

In addition to our shears, we offer many great machines to make cutting even faster and more effective.

The previously mentioned ROBUSO cordless shears are just one option of many:

We are German partner of the company GUNNAR from Switzerland.

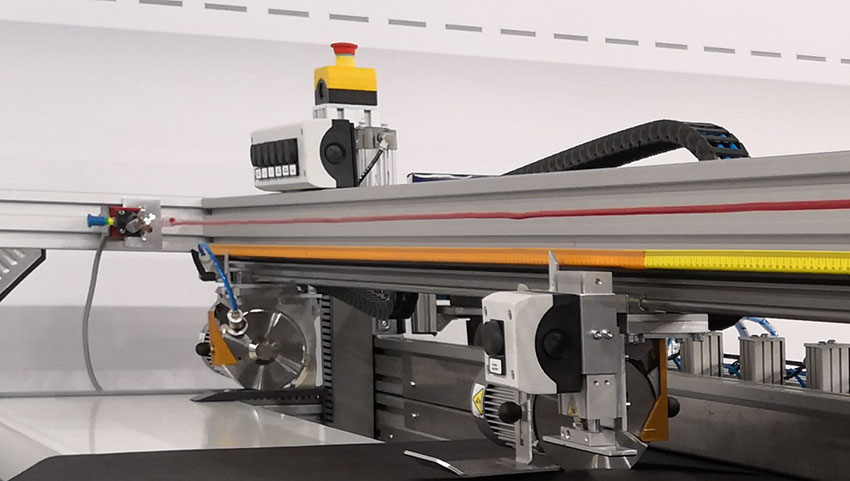

Together with GUNNAR we distribute the Novex, a machine for digital cutting in single ply cutting of composite materials.

The fantastic thing about the Novex is the great modularity of the machine. The machine can grow with the customer’s requirements.

With a special nesting software, it is possible to arrange the parts to be cut on the material in a space-saving way. This alone allows material savings of up to 30% per year. Depending on the material costs, this can almost finance the entire machine.

A great argument for every production manager to convince his purchasing department to buy.

Furthermore, we have been a partner of RASOR for several years now. Among other things, RASOR specializes in the construction of OEM/build-in machines. This has opened up many great new markets for us. If material is to be cut to length from a roll (cross cut) or the material is to be trimmed on the sides, the RASOR machines are a very great solution, which we have already integrated into existing systems many times together with our customers.

So, we offer cutting solutions for pretty much any material.

Glass and carbon fiber (also prepreg), aramid, PBO, Dyneema and many more.

Challenge us and send us your materials. We will find a solution to cut it!

E.E: At what stage is the market where you are currently active?

ROBUSO: The pandemic is actually causing all of our markets to ride a roller coaster. Markets that were just on the upswing suddenly drop again due to supply bottlenecks of materials, etc.

We will have to endure a few more difficult months before we will see a halfway normal situation on the markets again.

E.E: What can you tell us about market trends?

ROBUSO: New materials are being found all the time to further advance lightweight construction and thus possibly become even more environmentally friendly.

We are receiving an increasing number of requests for cutting solutions for basalt or flax. On the other hand, more and more companies are trying to recycle composite materials in a reasonable way.

This results in new challenges for us.

E.E: What are the most innovative products marketed?

ROBUSO: In the area of our shears, we are trying to extend the life time of the shears more and more with a wide variety of coatings. We also regularly put the grinding patterns to the test in order to obtain an even better result with minimal changes, if necessary. For this purpose, we work very closely with our customers from the industry. This has already resulted in many great new models in the past.

As far as the machines are concerned, we are trying to increase the performance even further by using better and better batteries, while at the same time reducing the weight so that the machines become even more ergonomic.

E.E: What estimations do you have for 2022?

ROBUSO: We hope that the pandemic will finally come to an end in 2022 and that the economy will recover and stabilize.

For this time, we expect huge growth in all areas. We are already preparing for this today with increased production of stock goods in order to be able to cope with the great rush on our products.

Contact us if you want to improve your cutting process with a better cutting result and/or a longer life time of your products.

You do not know what the right cutting solution is right now? Just send us your sample material!

We also have a very nice online shop where you can place your order directly! Of course, we ship worldwide.

You also can add and contact us via LinkedIn.

ROBUSO STAHLWARENFABRIK BUNTENBACH & SOHN GMBH

Gleisdreieck 13, 42651 Solingen, Germany

Stephan KRUEGER

Tel.: +49-212-233625-0

Shop: www.robuso.de