ROCKETSOLUTION is an independent technology manufacturer in the field of intralogistics and specializes in the development of highly standardized, automated storage and retrieval systems of the latest generation. Since March 2021, ROCKETSOLUTION’s highly automated storage system RSX1 has been available on the market. The system is specially designed for the storage of totes and trays up to 50 kg. The RSX1 is flexibly scalable and can be used in different industries and application areas. The RSX1 can be implemented both as the central storage component of an individual intralogistics system (RSX1-Enterprise) and as a standardized fulfilment center (RSX1-Micro).

Interview with André Nowinski, General Manager at ROCKETSOLUTION.

Easy Engineering: What are the main areas of activity of the company?

André Nowinski: With the RSX1 technology, ROCKETSOLUTION delivers an efficient storage and retrieval solution for different warehouse sizes and fields of applications. Thus, the micro-fulfilment solution RSX1-Micro is a fully functional complete system especially suitable for urban warehouses or smaller automated systems e.g., within retail shops. The turnkey, standardized fulfilment center includes conveyor technology and various workstations, material flow control, an integrated warehouse management system. The integrated system solution RSX1-Enterprise, however, is a core high performance storage unit for individually planned and holistic intralogistics systems like comprehensive warehouses, distribution centers or buffer storages.

E.E: What’s the news about new products?

A.N: The RSX1 shuttle combines the advantages of an enormous storage density with a robust handling of standard of market totes while being easily integrated in every system landscape.

E.E: What are the ranges of products?

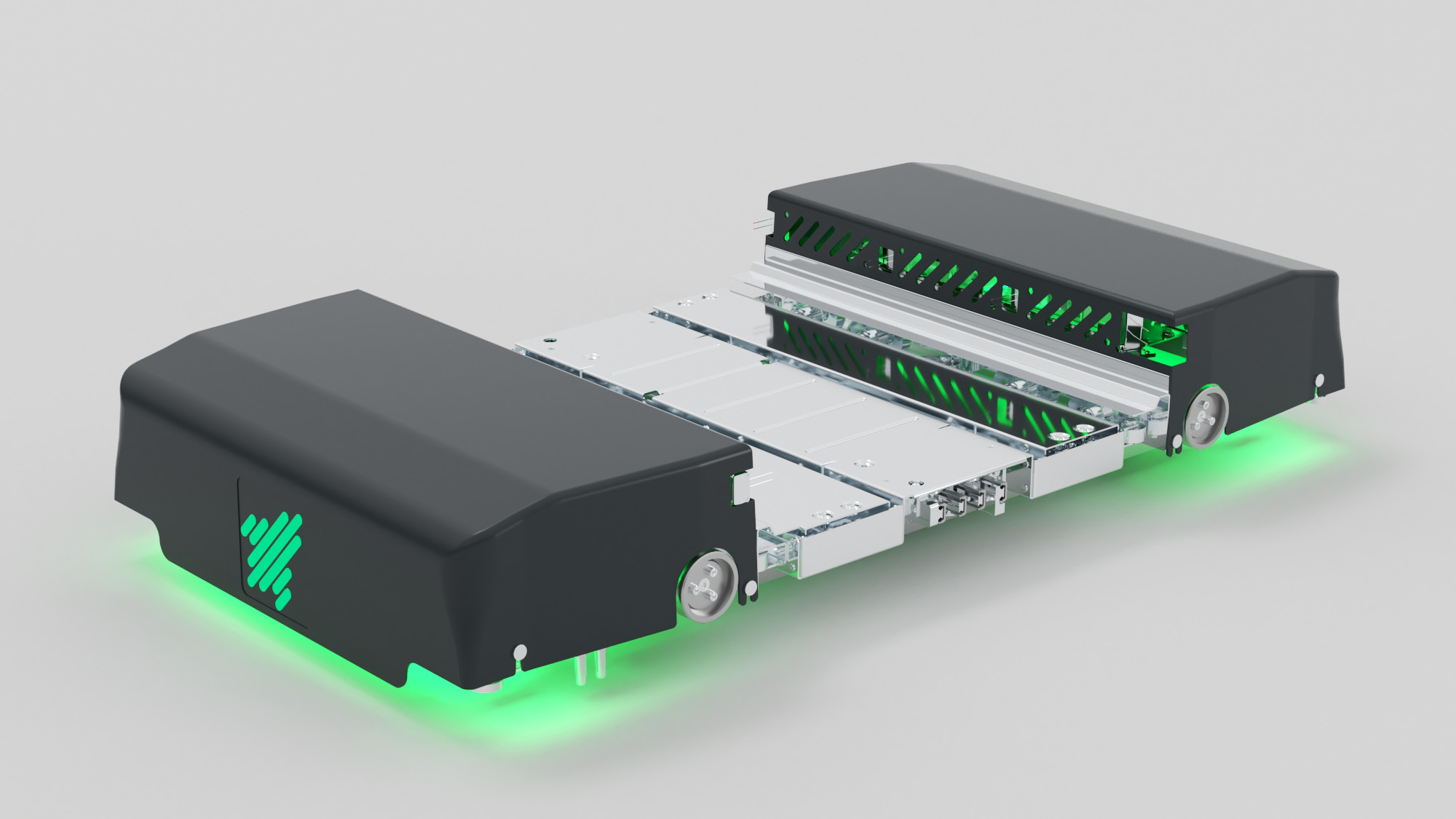

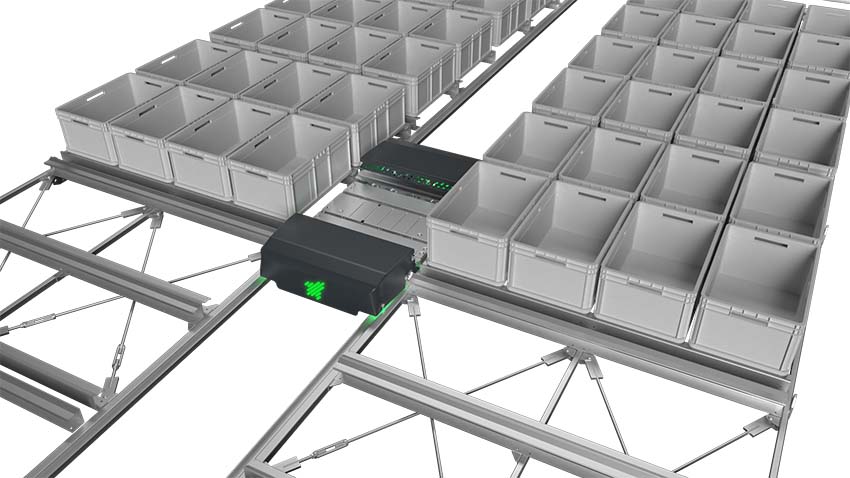

A.N: The four core components: RS-Rack, RS-Shuttle, RS-Lifts and RS-Software form the innovative RSX1 shuttle system by ROCKETSOLUTION. The configurable and expandable racking system RS-Rack with a maximum height of 30m, low floor requirements and its intelligent, space-saving access concept is the basis. The RS-Shuttles are high-performance shuttle vehicles that travel within this racking system. They can effectively pick up small parts weighing up to 50kg and handle the orders from one or more storage levels, depending on the performance requirements. The RS-Lifts can be positioned anywhere in the rack, and the number of lifts can be scaled according to the required system performance. Tote transfers between shuttle and lifts are done in a way that conserves space and without the need of additional conveyor technology. The system is rounded off with the future-proof RS-Software that comes with a standardized, highly flexible IT interface to external material flow and warehouse management systems already covering all sequencing requirements. A modern app-based user interface facilitates handling. IoT data is provided via MQTT.

E.E: At what stage is the market where you are currently active?

A.N: Intralogistics is a rapidly growing market worldwide with huge potential to contribute to the sustainable protection of our environment. High performance in the smallest space – that is the demand of today’s storage solutions in intralogistics. At the same time the desire for improving profitability grows as well. Thus, achieving higher profits while increasing durability is the challenge. ROCKETSOLUTION wants to solve today’s and future economic and ecological challenges and offers excellent solutions to optimize the intralogistics sector.

E.E: What can you tell us about market trends?

A.N: New game changers in the retail such as click & collect services and same-day delivery, which are essential for the industrial networking and securing of supply chains underline the need for secure and reliable technology. Seasonal fluctuations and unexpected growth in the face of tougher competition require high system performance and the ability to scale. At the same time, individual IT interfaces and complex control systems are becoming organisational as well as economic knock-out criteria due to a diversity of application fields of automation technology.

In summary, the following requirements must be met by innovative, future-proof automation solutions in intralogistics:

- Maximum space efficiency

- High performance

- Process reliability / reliable system availability

- Easy integration (IT interfaces & building structure)

- Scalability (size & performance)

E.E: What are the most innovative products marketed?

A.N: ROCKETSOLUTION’s RSX1 offers flexible storage solutions for all types of industries and applications. The shuttle vehicle’s unique load handling device and ultra-compact design allow for greater lateral bin density, reduced aisle width and quadruple-deep storage. As a result, the required size of the shuttle warehouse can be reduced by half. All RSX1 components such as racking, adaptable lifts and innovative shuttle vehicles reduce unnecessary empty space within the storage system. It also conserves resources and increases efficiency and profitability in small parts storage.

E.E: What estimations do you have for 2022?

A.N: We finish our first installations and hand them over to our customers. So even from this perspective 2022 is a great milestone for Rocket solution. Beside that we see a huge interest from customers, planning consultants and integration partners fueled by live presentations like Logimat tradefair. This gives us the possibility to get new people on board and to roll out RSX1 into the next markets.