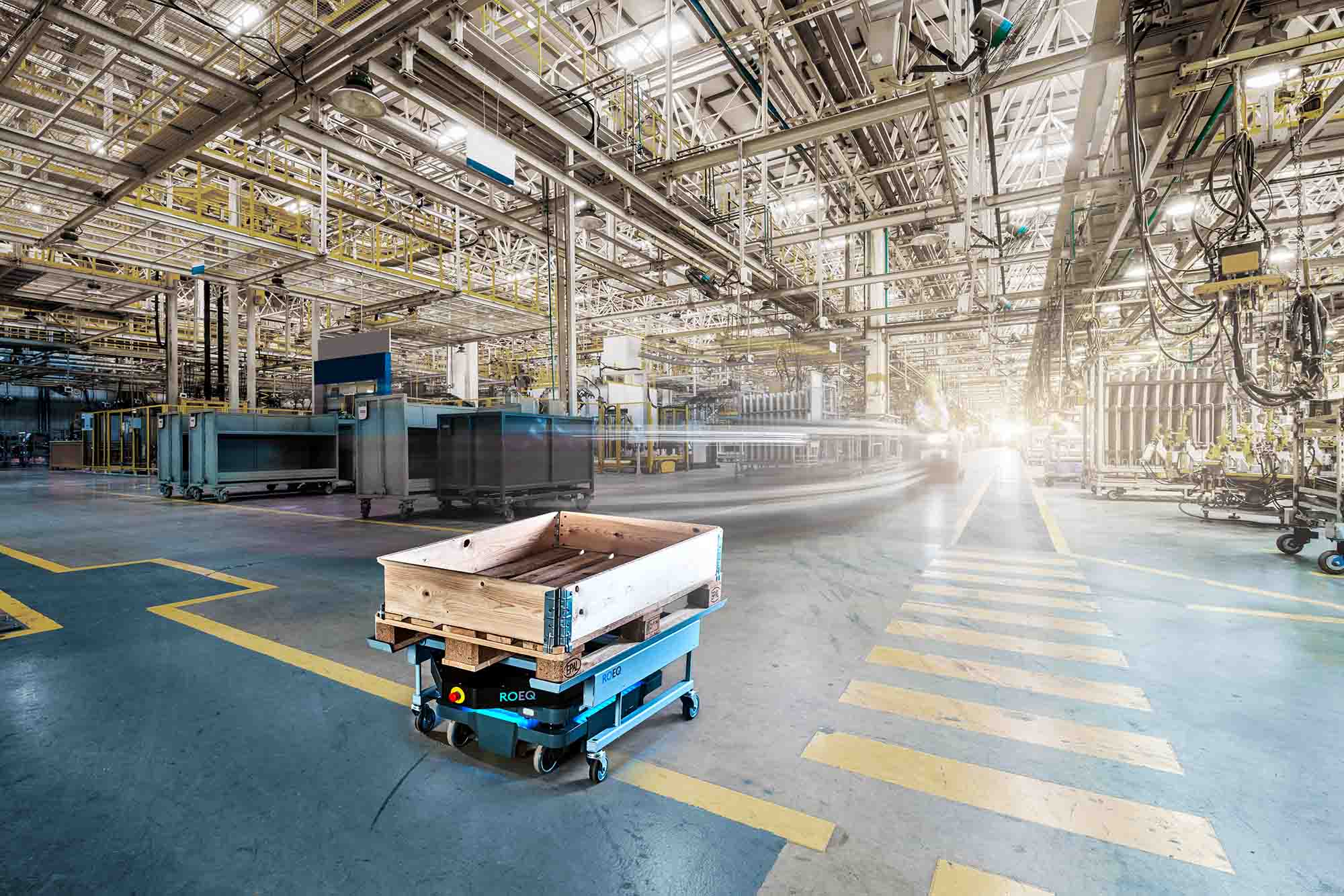

ROEQ is a Danish company founded in 2017 by 3 engineers, Michael E. Hansen, Benni S. Lund and Carsten Sørensen with engineering consulting backgrounds servicing the big pharma companies in the medical industry. During a consulting project for MiR, they found out that there’s a gap in the adoption of autonomous mobile robot (AMR) technology where mobile robotic equipment are required to work as eyes and limbs of the AMR in facilitating intralogistics. This led to the founding of ROEQ where we develop, manufacture and supply cart, rack, lifter and conveyor solutions for the industry segment via our partner network of more than 80 partners spanning across 40 countries.

Coupled with the founders’ extensive experience working with multinational companies in the medical industry, they see that standard and ready to be adopted mobile robotic equipment is the way forward to bridge the stringent requirements and expectations on reliability, safety and ease of use of the multinational companies.

Easy Engineering: What’s the news for 2021 about new products?

ROEQ: We have released 2 more S-Cart variations for our existing S-Cart300 solution depending on the application. We will continue to launch new products in 2021 but we are unfortunately unable to provide more info. prior to the launch date.

E.E: What are the ranges of traded products?

ROEQ: They are our cart, rack, lifter and conveyor solutions for all MiR robot platforms. We have about 30 products offers solutions to solve a large majority of industrial MiR AMR application needs

E.E: At what stage is the market where you are currently active?

ROEQ: The mobile robotic industry space where we are offering standard and ready to adopt solutions that are highly focused on safety, ease of use and reliability is still in the early stage in the market. The market has been used to customizing their own solutions to complete an AGV or AMR application which often means insufficient testing and use in the market, higher cost of development and engineering, longer time to market as solutions could not be showcased or demonstrated easily to interested customers due to the time consuming research and development time.

E.E: What can you tell us about market trends?

ROEQ: We believe that we’ll see an increase adoptions of AMR technology on a global level; particularly in North America and Europe and that mobile robotic equipment will play a crucial role in supporting the success of AMR implementations. It will be the technology of these mobile robotic equipment that supports the success of AMR adoptions and implementations. There will also be a huge focus on having reliable automation, automation that is safe and can work collaborative with workers and technology that is easily accessible to bring down the barriers of accessing new technologies.

E.E: What are the most innovative products marketed?

ROEQ: It is no doubt that ROEQ GuardCom System that works with our top roller modules has been an innovative technology for our customers. It helps to build and make business cases more attractive to implement the MiR AMRs in their production facilities to facilitate the transfer for goods between MiR robot and ROEQ conveyor solutions and the existing stationary conveyors stations in their factories.

E.E: What estimations do you have for 2021?

ROEQ: We have been growing despite the difficult COVID19 times and we expect to see a stronger focus on automation going forward and therefore, expecting ROEQ to follow this upward trend of adoptions and to continue our strong growth we are experiencing in 2020.