Created in 2006, RX Solutions has developed a broad range of high performance of X-ray radioscopy and microtomography systems and offers also fast CT scanning and inspection services.

The RX Solutions’ micro and nano CT systems are recognized for their high performance, their flexibility and reliability. They are widely used by academic research labs as well as by industrial companies for non-destructive tests in R&D, quality assurance or production process control.

Easy Engineering: What are the main areas of activity of the company?

RX Solutions: X-ray CT technology, provided by RX Solutions has become, an essential technology for non-destructive 3D characterization. It is widely used in many industries, such as aerospace, spatial, medical devices, plastic injection, composite material or additive manufacturing where X-ray CT contributes to shorten the product development cycle in R&D, to accelerate failure analysis and to improve quality assurance and production process control.

X-ray CT technology is of interest for industrials that produces parts with high added value or that are critical from a safety point of view. These parts often have internal structures that are inaccessible to traditional inspection systems.

E.E: What’s the news about new products?

RX Solutions: X-ray CT is an innovative market, on hardware and software aspects. The performances on both sides have steadily increased in recent years and continue to be, even if it faces on some points physical limitations.

Scanning times are now reaching reasonable durations. Computation times have been considerably reduced thanks to the use of GPU-type graphics cards to parallelize the calculations. In some cases, this has reduced them from hours to minutes. The resolutions offered by micro-tomographs are now also perfectly adapted to the most common manufactured parts.

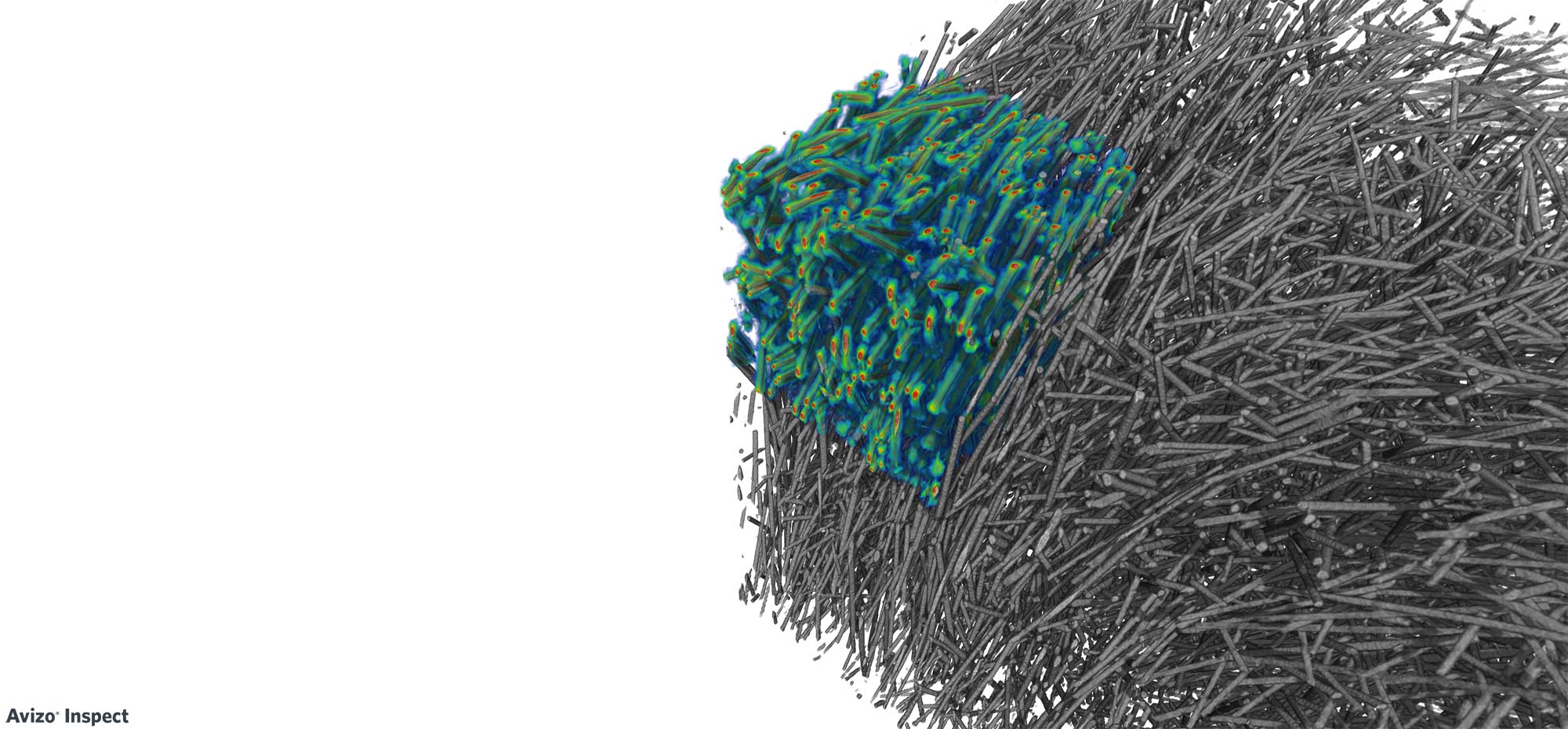

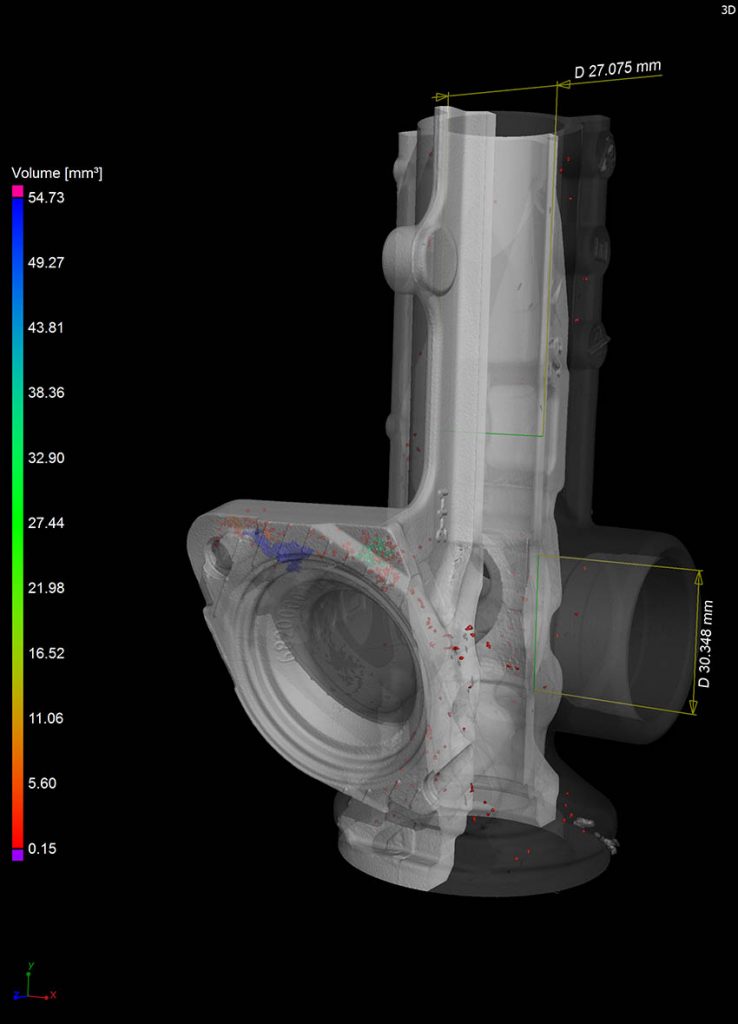

The range of analyses that can be performed by dedicated software is constantly expanding. For example, it is possible to carry out porosity analyses or to simulate fluid transport or mechanical stress phenomena using the digital model of a real part obtained by tomography.

X-ray detectors will continue to evolve to become more efficient, faster and more sensitive. Spectrometric detectors will provide additional information. Detectors of this type are currently being evaluated and integrated at RX Solutions. The X-ray generators also continue to progress by specialising (high energy or high resolution) depending on the application.

E.E: What are the ranges of products?

RX Solutions: RX Solutions offers complete and powerful X-ray CT systems with the finest level of detail: resolution down to sub-micron level, covering both industrial and academic applications. RX Solutions CT systems portfolio covers a large scale of analysis, from Microfocus (4 μm) to Nano focus (0.4 μm) to satisfy a broad spectrum of applications.

E.E: At what stage is the market where you are currently active?

RX Solutions: X-ray computed tomography is a growing market, whose precursors were academics who equipped themselves about ten years ago, followed today by many industries, which see all the potential of this technology to improve and reinforce their quality processes.

E.E: What can you tell us about market trends?

RX Solutions: There is a continuing growth of the X-ray CT market as this technology offer a multitude of advantages, such as obtaining the internal structure of an object nondestructively, validating extremely accurate internal geometries, allowing comparisons to reference models and being able to scan any type of part with all shapes and sizes with extremely high resolution.

There is an increasing interest in applying CT technology into many industries such as Aerospace and defense, automotive, medical devices, plastic injection and many more. The primary drivers include customers demanding higher quality inspection controls that cannot be provided by optical or traditional measuring technologies and a desire for improved product quality, opening up new customer bases.

E.E: What are the most innovative products marketed?

RX Solutions: X-ray CT is a non-destructive testing technique that provides information about both the internal and external structure of a part. It enables material health checks to be carried out while verifying the positioning of the various elements of an assembly and carrying out dimensional measurements. The images delivered are very easily interpreted without specific expertise.

As a multiscale technology, X-ray CT can be used to assess a complete assembly as well as the microstructure of tiny components, in a single equipment.

Furthermore, X-ray goes from R&D labs to manufacturing plants, as a holistic means to fully inspect and qualify assemblies and parts. RX Solutions’ X-ray CT systems can also be used on a production line. They can be combined with automatic loading and unloading devices as well as Automatic Defect Recognition (ADR) software. The entire scanning and analysis process of our equipment is already automated. However, it is possible to design a system specifically for an application. Note that it is important to ensure that the cycle time of the tomograph is in line with the cycle time of the part to be inspected. An automatic tomography system installed inline requires a relatively high investment. It is therefore more suited to the inspection of parts with high added value There is a continuing growth of integrated metrology within new manufacturing plants, in many different manufacturing fields.

E.E: What estimations do you have for 2022?

RX Solutions: With the intensification of growth in the different markets addressed by X-ray CT technology, we expect a continuous growth on 2022. X-ray CT as the major benefit to be integrable at each step of a product life cycle. There is a continuing growth of integrated metrology within new manufacturing plants, whatever the industry and X-ray CT is the only technology to visually inspect in a non-destructive way the internal features of assemblies and components.